Method for preparing high-purity transparent silica micro powder for pouring sealant

A technology of silica and potting glue, applied in the direction of silica, silica, etc., can solve the problems of poor wettability, easy ion migration, poor electrical properties, etc., and achieve good crack resistance, high transparency, and good transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

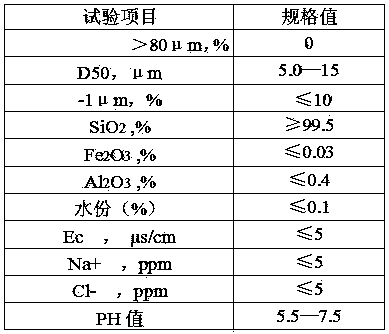

[0020] Embodiment 1, a kind of preparation method of the high-purity transparent silicon dioxide micropowder that is used for encapsulant, its steps are as follows:

[0021] (1) Raw material selection: use manual crushing to obtain quartz blocks with a particle size of ≤10cm and a particle size of 20-50cm as raw materials, and SiO in the quartz block raw materials 2 Content≥99.7%, moisture≤0.1%, Fe 2 o 3 ≤0.03%, Al 2 o 3 ≤0.03%;

[0022] (2) Pre-crushing of raw materials: two raw materials with a particle size of ≤10cm and a particle size of 20-50cm are put into a dry ball mill for crushing according to a weight ratio of 1:1, and a semi-finished powder with D50= 5μm is obtained;

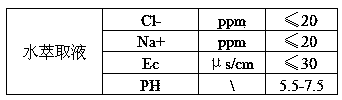

[0023] (3) Powder block preparation: add the aforementioned semi-finished powder into the wet ball mill, and add pure water into the wet ball mill. The weight ratio of semi-finished powder to pure water is 2:4. After grinding for 10 hours, D50= 5 μm slurry, wherein the slurry with a particle siz...

Embodiment 2

[0025] Embodiment 2, in the preparation method according to embodiment 1, its steps are as follows:

[0026] (1) Raw material selection: use manual crushing to obtain quartz blocks with a particle size of ≤10cm and a particle size of 20-50cm as raw materials, and SiO in the quartz block raw materials 2 Content≥99.7%, moisture≤0.1%, Fe 2 o 3 ≤0.03%, Al 2 o 3 ≤0.03%;

[0027] (2) Pre-crushing of raw materials: two raw materials with a particle size of ≤10cm and a particle size of 20-50cm are put into a dry ball mill for crushing according to a weight ratio of 1:5, and a semi-finished powder with D50= 30μm is obtained;

[0028] (3) Powder block preparation: add the aforementioned semi-finished powder to the wet ball mill, and add pure water to the wet ball mill. The weight ratio of semi-finished powder to pure water is 8:10. After grinding for 40 hours, D50= 15μm slurry, wherein the slurry with a particle size of less than 1μm≤10%; put the slurry into a wooden barrel covered...

Embodiment 3

[0030] Embodiment 3, in the preparation method according to embodiment 1, its steps are as follows:

[0031] (1) Raw material selection: use manual crushing to obtain quartz blocks with a particle size of ≤10cm and a particle size of 20-50cm as raw materials, and SiO in the quartz block raw materials 2 Content≥99.7%, moisture≤0.1%, Fe 2 o 3 ≤0.03%, Al 2 o 3 ≤0.03%;

[0032] (2) Pre-crushing of raw materials: two raw materials with a particle size of ≤10cm and a particle size of 20-50cm are put into a dry ball mill for crushing according to a weight ratio of 1:3, and a semi-finished powder with D50= 20μm is obtained;

[0033] (3) Powder block preparation: add the aforementioned semi-finished powder into the wet ball mill, and add pure water into the wet ball mill. The weight ratio of the semi-finished powder to pure water is 5:8. After grinding for 25 hours, D50= 10μm slurry, wherein the slurry with a particle size of less than 1μm≤10%; put the slurry into a wooden barrel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com