Hydrophobically associating dimethyl diallyl ammonium chloride cation flocculating agent and preparation method thereof

A technology of dimethyl diallyl ammonium chloride and cationic flocculants, which is applied in the chemical industry, can solve problems such as not being able to meet the requirements of sewage treatment, and achieve low production costs, stable performance, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

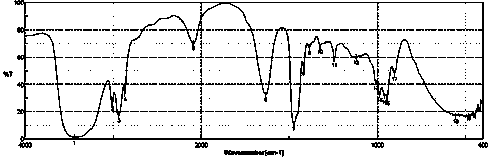

Embodiment 1

[0030] Weigh 270 g of 65% DMDAAC solution, 13.00 g of 1% disodium ethylenediamine tetraacetate, 1.68 g of ammonium persulfate and 7.82 g of deionized water in 1000 ml with four ports equipped with mechanical stirring, thermometer, condenser tube and nitrogen inlet In the flask, nitrogen was passed through to remove oxygen for 30 minutes under stirring, and the reaction was carried out at 45°C and 55°C for 3 hours respectively, and then at 70°C for 24 hours, and an appropriate amount of deionized water was added to the discharge. The solid content is 39.97%, [η]=0.98 dL / g of the unrefined sample, M=15.12×10 4 , [η]=1.02 dL / g of refined sample, M=16.12×10 4 .

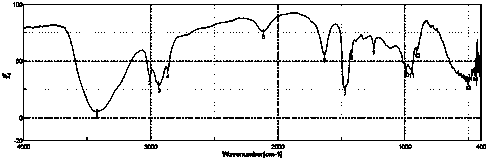

Embodiment 2

[0032]Put 270.00 g of 65% DMDAAC solution, 15.50 g of vinyl isobutyl ether, and 13.00 g of 1% disodium edetate in a 1000 ml four-necked flask equipped with mechanical stirring, thermometer, condenser tube and nitrogen inlet, and stir After deoxygenation with nitrogen for 30 min, add 15.00 g of 1% V-50 solution and heat to 50 °C, react at this temperature for 6 h, and then react at 75 °C for 20 h, adding an appropriate amount of water to control the viscosity of the system , The solid content of the final product is 40.0%. Kinematic viscosity at 25°C > 60000 mpa s, intrinsic viscosity [η] of the product is 1.01 dL / g, M=15.83×10 4 , [η]=1.06 dL / g, M=17.05×10 4 .

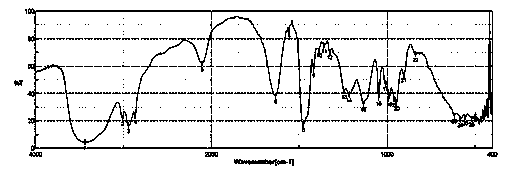

Embodiment 3

[0034] Mix 90.00 g of 65% DMDAAC solution, 2.86 g of diethylene glycol divinyl ether, 3.60 g of 1% disodium edetate, and 0.18 g of ammonium persulfate in 250 ml with mechanical stirring, thermometer, condenser and nitrogen In the imported four-neck flask, after stirring with nitrogen for 30 min, add 5.80 g of 1% sodium bisulfite solution and heat to 45 °C, react at this temperature for 6 h, and then react at 75 °C for 20 h , during which an appropriate amount of water is added to regulate the viscosity of the system, and the solid content of the final product is 33.5%. The intrinsic viscosity [η] of the product is 0.77 dL / g, M=10.57×10 4 , the [η] of the refined sample is 0.79 dL / g, M=10.98×10 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com