Narrow-hysteresis submicron-scale shape memory alloy film and preparation method thereof

A memory alloy and hysteresis sub-technology, which is applied in the field of narrow hysteresis submicron shape memory alloy film and its preparation, can solve the problems of large phase transition lag and hinder the application of Ni-Ti alloy, and achieve the effect of increasing the working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

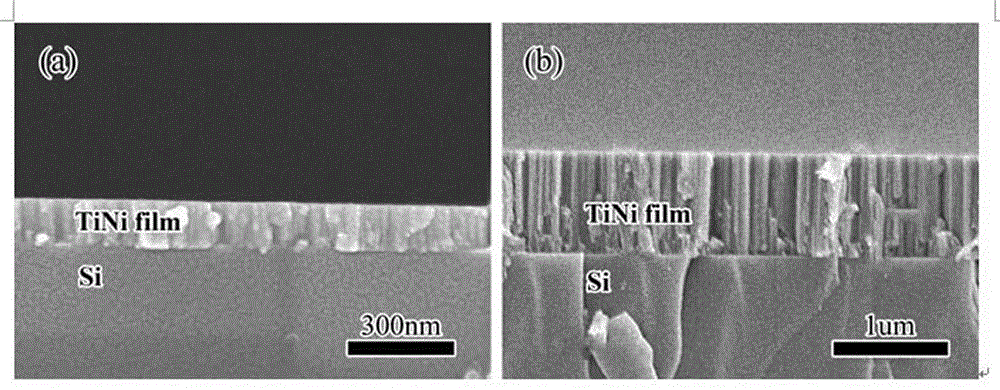

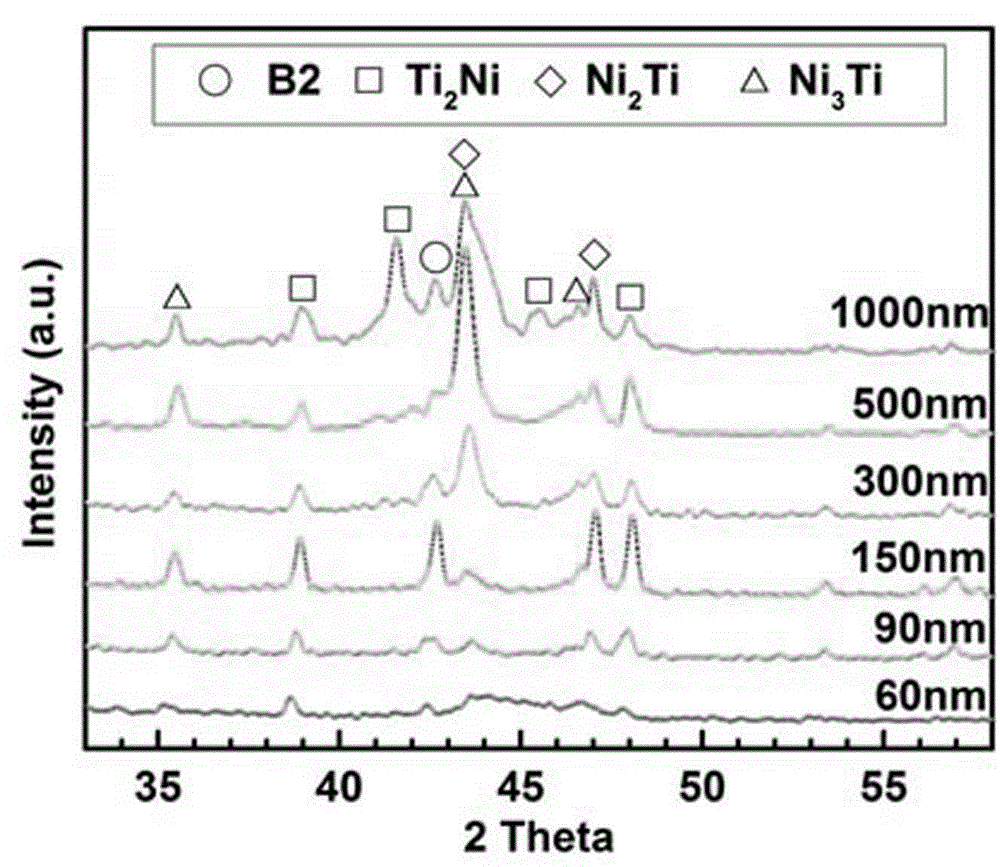

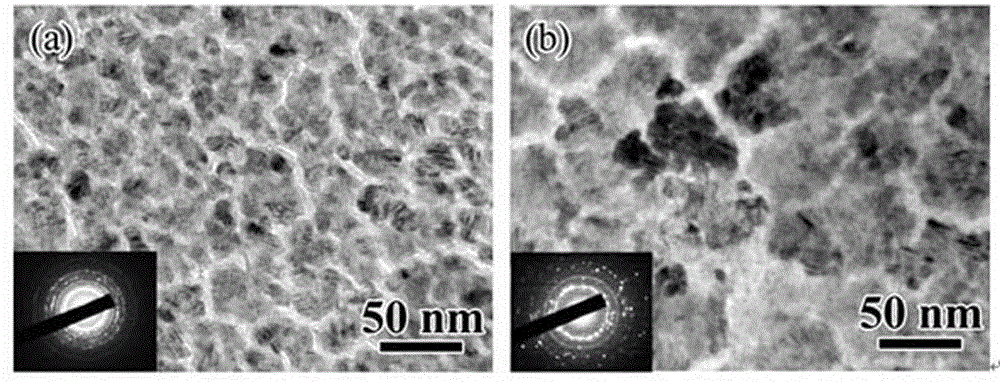

[0022] The narrow hysteresis and submicron shape memory alloy thin film of the present invention is composed of two elements, Ni and Ti, wherein the atomic ratio of Ni element is 48-49%, and the atomic ratio of Ti element is 52-51%.

[0023] 1. Put the p-type (111) oriented Si single wafer in an acetone solution and ultrasonically clean it for 30 minutes to obtain a clean Si surface for growing thin films;

[0024] 2. Fix the cleaned Si substrate on the disk fixture, and then place it on the co-sputtering table of the sputtering platform;

[0025] 3. Select pure metal Ni and Ti targets, and the atomic percentage of purity is 99.995%. Place the target on two DC target platforms, and adjust the inclination angle of the two targets to 45 degrees to ensure that the center of the target is aligned with the co-sputtering platform;

[0026] 4. Use the mechanical pump to pump the cavity of the magnetron sputtering equipment to a vacuum higher than 6 Pa, then turn on the molecular pum...

Embodiment 2

[0035] The difference between this embodiment and the first embodiment is that the deposition time of the Ni-Ti thin film in step 8 is 29 minutes, and the rest of the steps are the same as those of the first embodiment.

Embodiment 3

[0037] The difference between this embodiment and the first embodiment is that the deposition time of the Ni-Ti thin film in step 8 is 40 min, and the rest of the steps are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com