Passive phase-change material cooling system for power battery of electric automobile

A phase change material, power battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of complex flow channel structure, extra power consumption due to leakage, large mass and volume, etc., and achieve heat dissipation effect. Ideal, simple system structure, improve the effect of effective output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

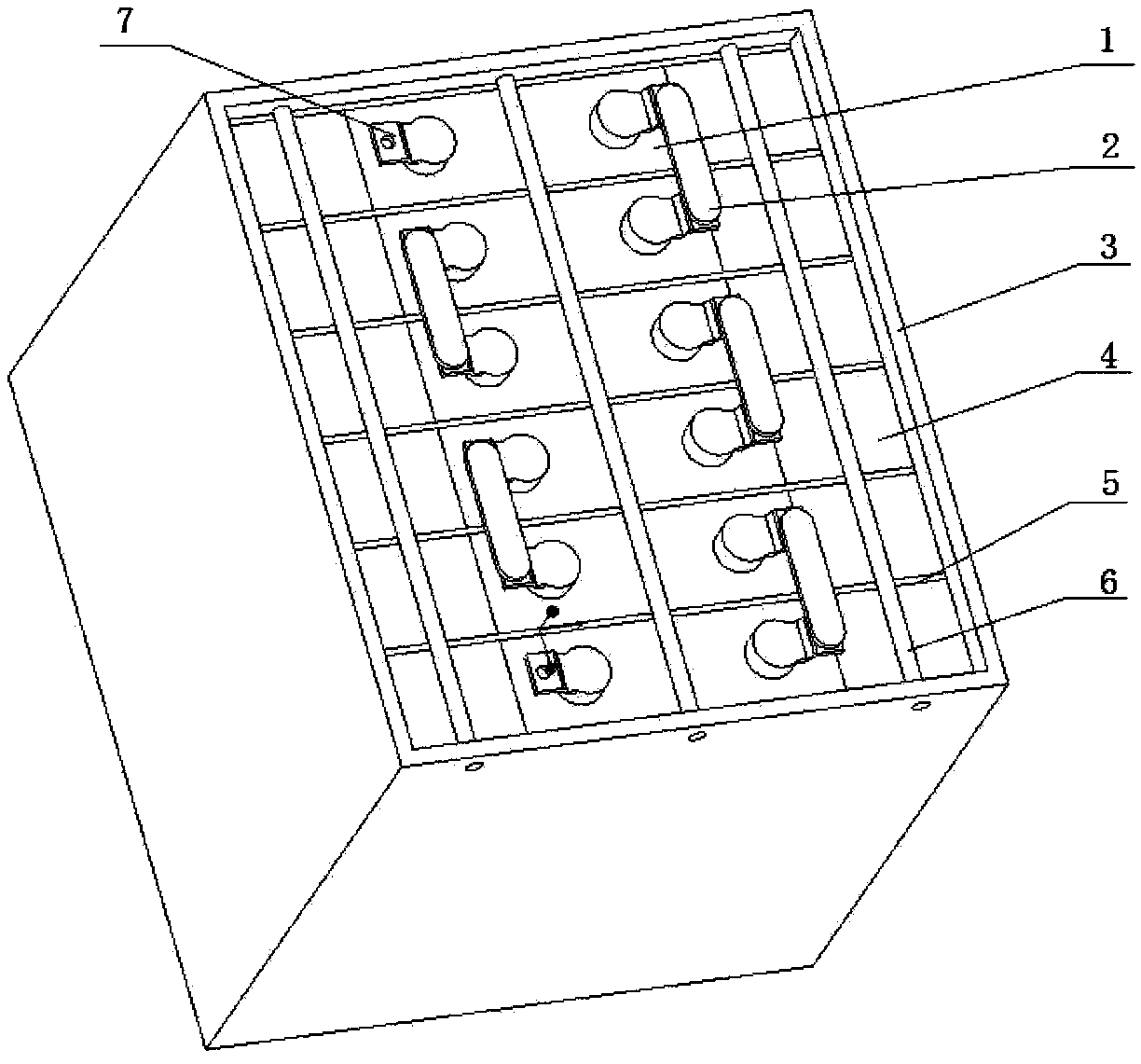

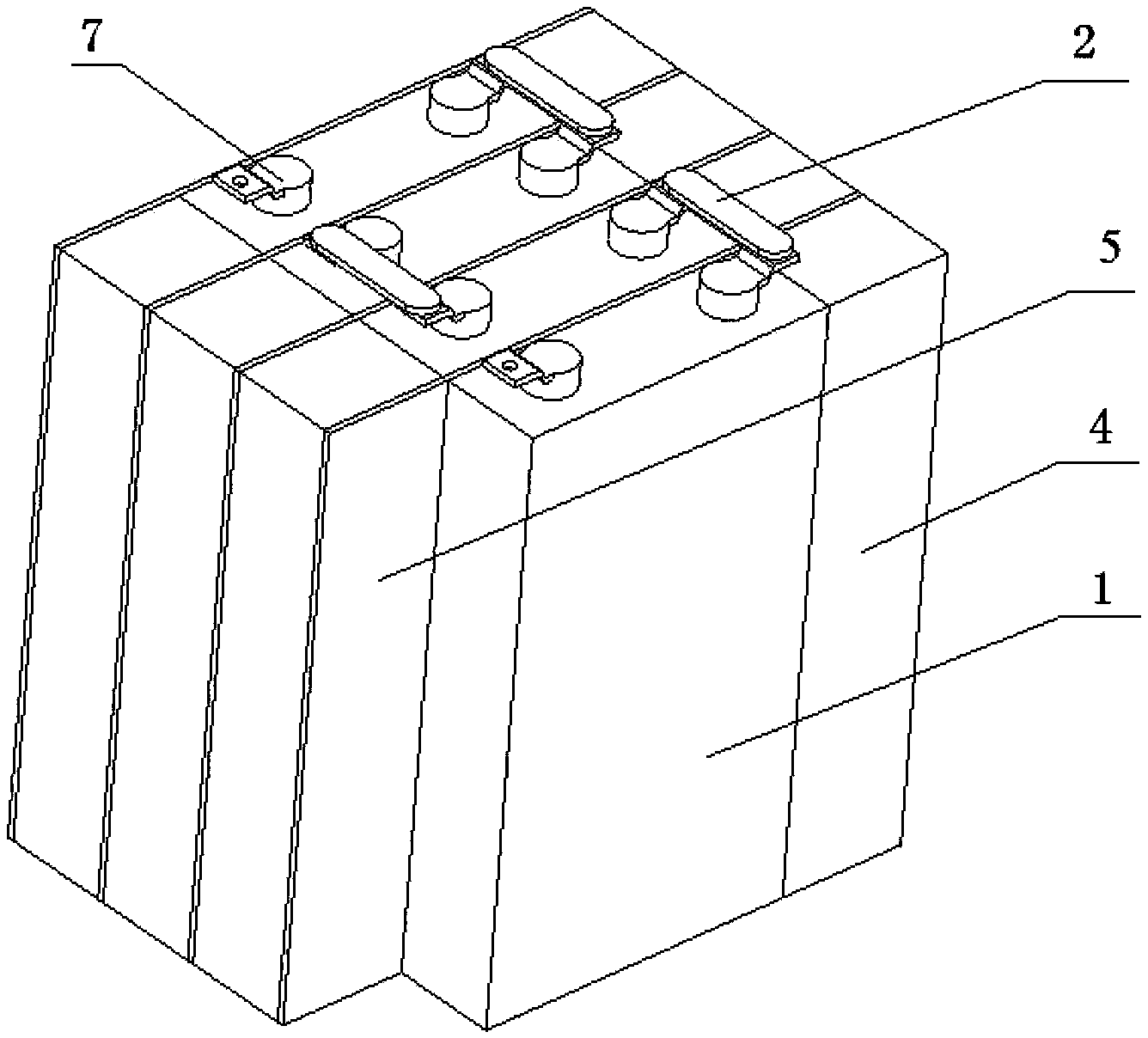

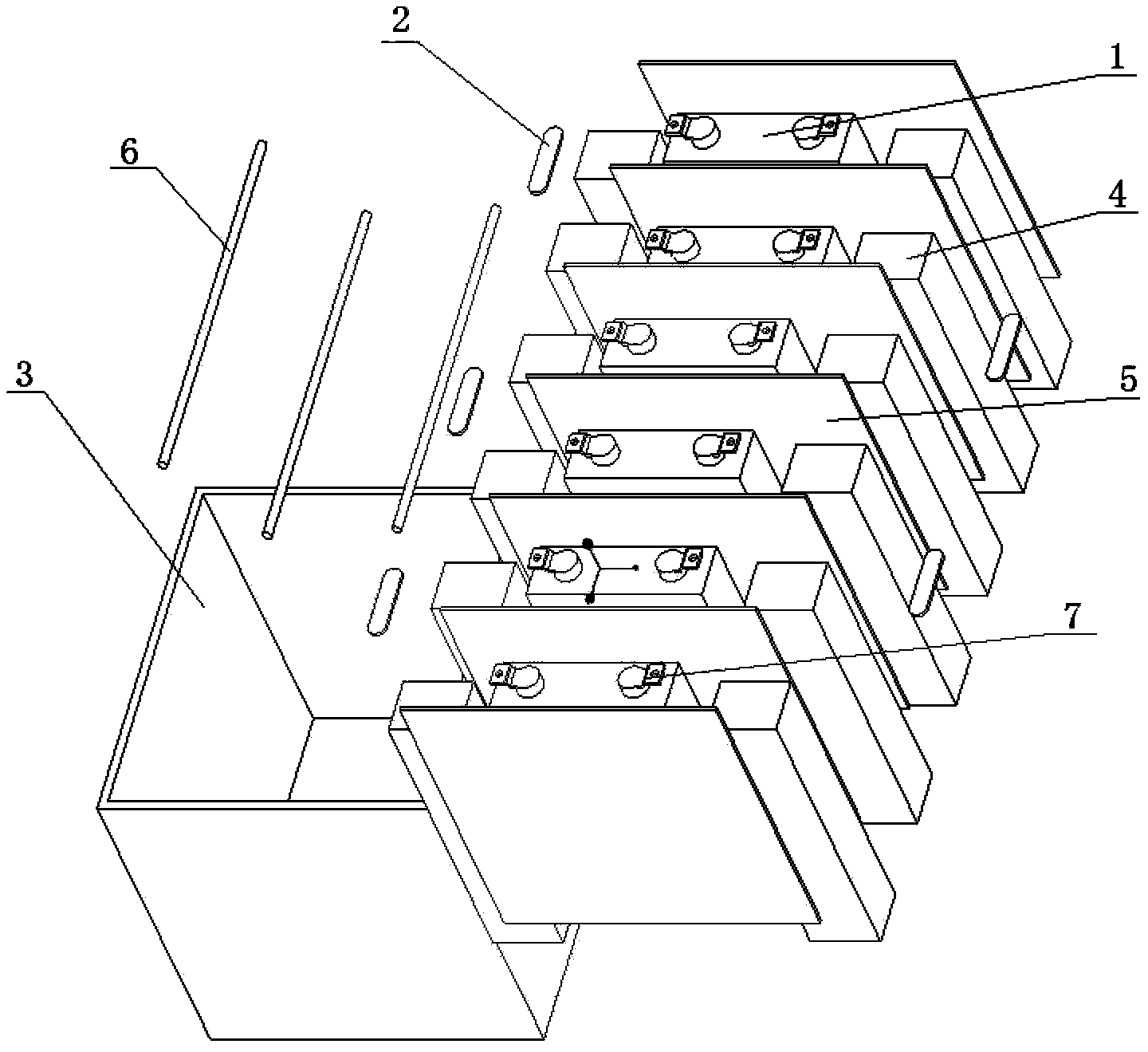

[0039] figure 1 It is a structural schematic diagram of a passive phase change material cooling system for a power battery of an electric vehicle according to the present invention, as figure 1 As shown in the example, the system includes:

[0040] A battery cell 1; and a battery module formed by connecting the battery cells through metal connecting pieces 2; a battery case 3 for accommodating one or more battery modules; a composite phase change material 4; and a battery module for maintaining temperature uniformity and High thermal conductivity graphite sheet 5 that transmits heat from the inside of the battery module to the peripheral composite phase change material; and threaded fasteners 6 for clamping the box.

[0041] like figure 2 , image 3 As shown in the embodiment, the composite phase change material 4 is symmetrically arranged on both sides of each battery cell 1, and the adjacent battery cells 1 are separated by a high thermal conductivity graphite sheet 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com