Sargassum fusiforme biscuit processing method

A processing method, hijiki technology, applied in the field of food deep processing, can solve the problems of hidden safety hazards, residual impurities, etc., and achieve the effect of easy absorption and utilization, low bacterial content and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The hijiki biscuit processing method of this embodiment includes the following steps: (1) soaking and cleaning, placing the hijiki material in clean water, washing away the salinity and sediment on the surface of the material, and the weight ratio of clean water to hijiki is 1:3 , soaking time 2h; (2) cooking, take out the soaked material and drain it and put it in a steamer for cooking, the cooking temperature is 100°C, and the cooking time is 2h; (3) vacuum drying, put it in an airtight container to heat and dry Simultaneously evacuate, the pressure in the container remains on 700Pa, drying time 40min, material moisture content 12% after completion; (4) screening, material is screened by vibrating sieve, 40 orders of vibrating sieve order, bud ear and stem are separated and Remove the stalks and keep the buds and ears; (5) acid-elute the arsenic, soak the screened materials in citric acid aqueous solution, the pH value of the citric acid aqueous solution is 2, and soak...

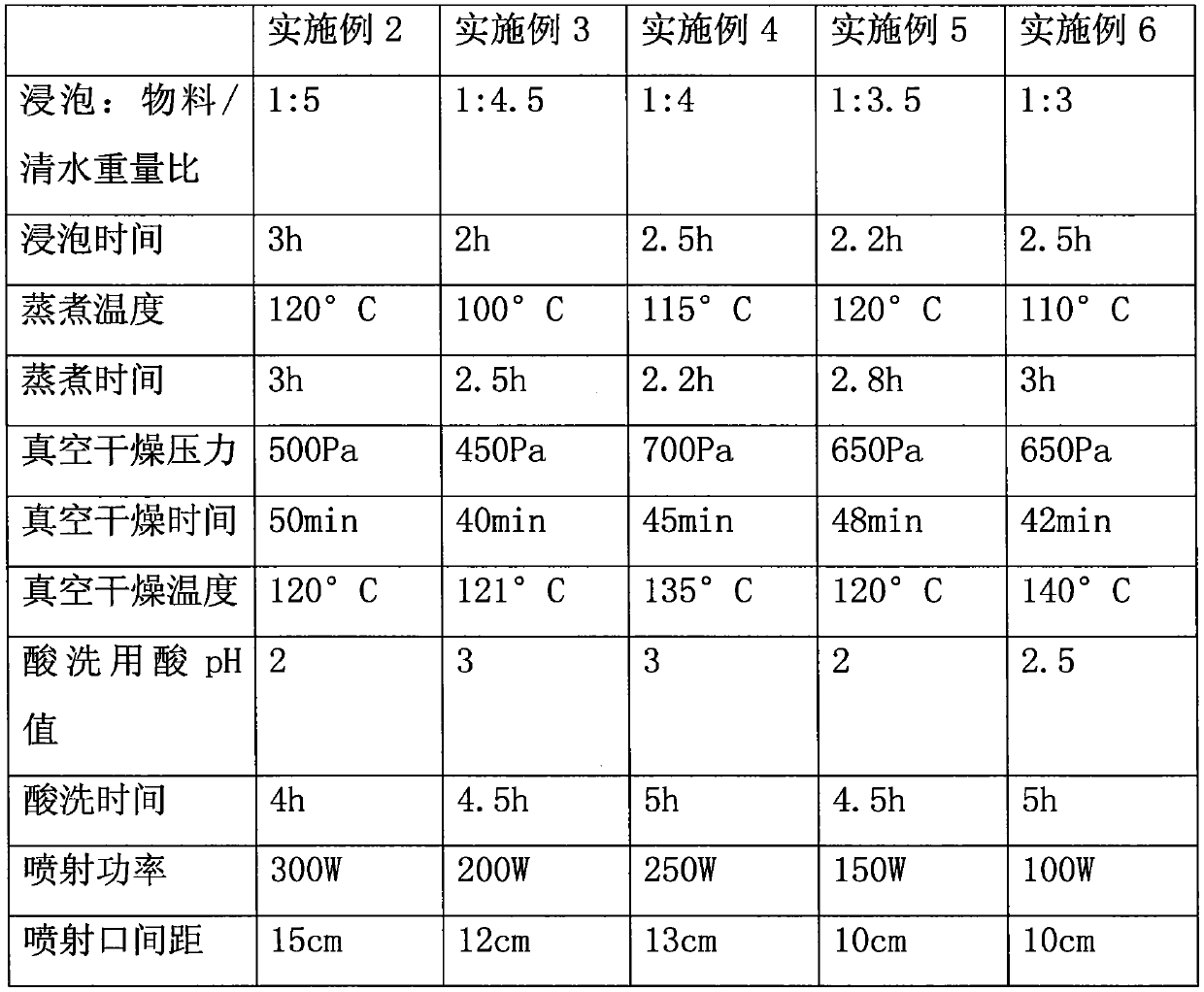

Embodiment 2-6

[0026] See Table 1 for the parameters of each step in Examples 2-6.

[0027]

[0028]

[0029] Table 1

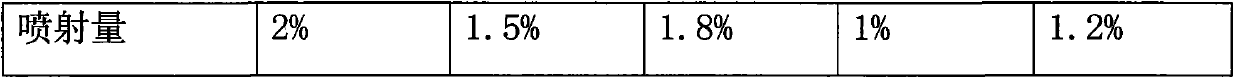

[0030] The components and specific gravity of the auxiliary materials in Examples 2-6 are detailed in Table 2 (the values in the table are the weight percentages of the ingredients relative to the total weight of the auxiliary materials).

[0031]

[0032] Table 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com