Technology and device for producing high-precision whole wheat flour

A production process and technology of whole wheat flour, applied in the direction of grain processing, etc., can solve the problems such as the production process of whole wheat flour that cannot remove the wheat husk, poor taste and taste of whole wheat flour, poor taste of whole wheat flour, bran, etc., to achieve Improvement of food production performance, simplification of production process, improvement of flour taste and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

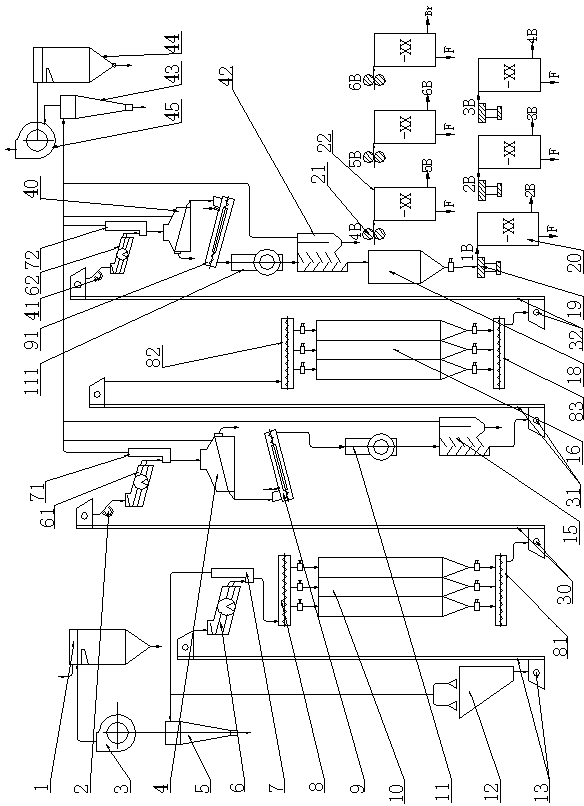

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

[0031] The high-precision whole wheat flour production process is composed of two parts: the barley process and the flour process. The barley process removes 60-70% of the peel. The flour process includes 6 skin mills, and each skin mill includes crushing and sieving. There are two processes, and the 1st to 3rd skin mills in the powder process use a high-speed extrusion mill. The minimum gap between the rotor pin and the stator pin of the high-speed extrusion mill is 0.5-1mm. The linear velocity of the outermost rotor pin must reach 95-120 m / s.

[0032] The barley process includes wool wheat cleaning (screening, wind separation, magnetic separation, second screening, second wind separation, stone removal), peeling (watering and stirring), light wheat cleaning (wind separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com