Ce:YAG based transparent ceramic being used for fluorescence conversion of white LED and containing Sr and preparation method thereof

A transparent ceramic and fluorescent technology, applied in the field of Sr-containing Ce:YAG-based transparent ceramics and its preparation, can solve the problems of unsatisfactory service life and decreased luminous efficiency, and achieve stable color temperature, soft white light, and high light decay resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

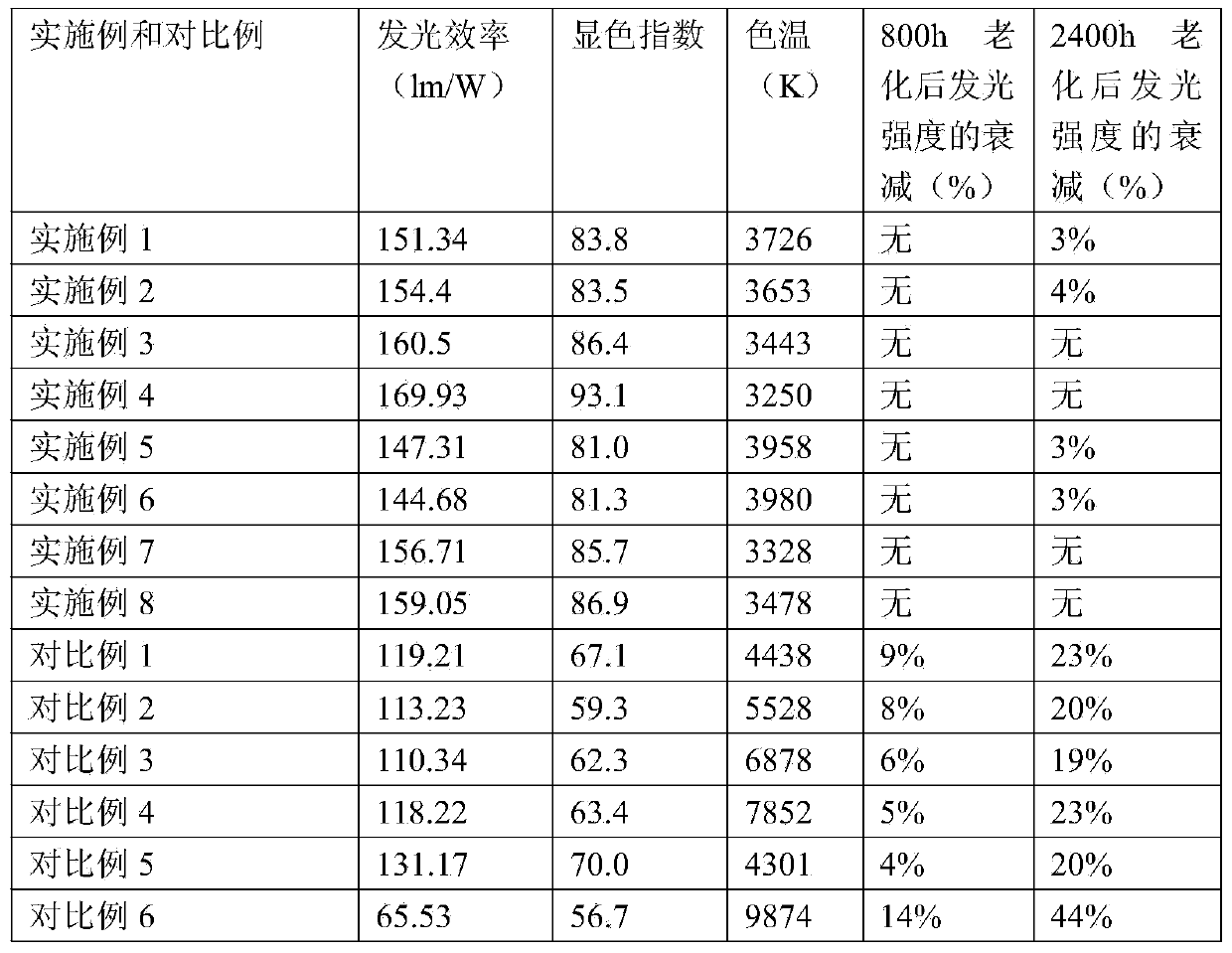

Examples

Embodiment 1

[0029] Use metal aluminum and magnesium as raw materials to react with isopropanol according to the required ratio to obtain metal alkoxide, then undergo vacuum distillation, dry in an oven, and roast at high temperature for 3 hours to obtain 75g of nano-MgAl 2 o 4 Powder. Using yttrium oxide (Y 2 o 3 ), alumina (Al 2 o 3 ), strontium oxide (SrO), cerium oxide (CeO 2 ) as raw material, according to (Ce 0.001 Sr 0.001 Y 0.998 ) 3 Al 5 o 12 Prepare 25g of powder raw materials, and then use wet ball milling to grind and mix the powder raw materials with absolute ethanol as the medium until the average particle size of the powder raw materials is 0.4 microns. Then add nano MgAl2 o 4 Powder, continue to ball mill until evenly mixed. The mixed powder is dried, sieved, and pressed into tablets; then it is subjected to 200MPa cold isostatic pressing to form a green body, and put into a vacuum sintering furnace for sintering at 1700°C for 20 hours to obtain a thickness of ...

Embodiment 2

[0033] Prepare and test MgAl in the same manner as in Example 1 2 o 4 / (Ce 0.03 Sr 0.03 Y 0.94 ) 3 Al 5 o 12 Transparent fluorescent ceramic.

Embodiment 3

[0035] Prepare and test MgAl in the same manner as in Example 1 2 o 4 / (Ce 0.01 Sr 0.01 Y 0.98 ) 3 Al 5 o 12 Transparent fluorescent ceramic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com