Novel nitrogen-phosphorus system halogen-free flame-retardant nylon 6 and preparation method thereof

A flame-retardant nylon and phosphorus-nitrogen-based technology, which is applied in the field of new phosphorus-nitrogen halogen-free flame-retardant nylon 6 and its preparation field, can solve the problems of poor thermal stability, high production cost of flame retardants, and high cost, and achieves improved performance. Thermal stability and flame retardant effect, high thermal stability, the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A novel phosphorus-nitrogen series halogen-free flame-retardant nylon 6 and a preparation method thereof, comprising two steps:

[0032] The first step is to mix aluminum diethylphosphinate, macromolecule charring agent, coupling agent, antioxidant and nylon 6 resin, and stir evenly;

[0033] Preferably, the macromolecular char-forming agent is: one or more of triazine linear, dendritic and hyperbranched macromolecules synthesized by the reaction of cyanuric chloride and ethylenediamine, or ethylenediamine.

[0034] Preferably, the coupling agent is: one of γ-aminopropyltriethoxysilane, γ-glycidyloxypropyltrimethoxysilane, γ-(methacryloyloxy)propyltrimethoxysilane species or several.

[0035] Preferably, the antioxidant is: tetrakis[β-(3,5-di-tert-butyl-4-hydroxy) phenylpropionate] pentaerythritol ester, or 1,1,3 tris(2-methyl-4-hydroxy- 5-tert-butylphenyl)butane.

[0036] Preferably, in terms of mass percentage, the added amounts of the raw materials are: 2-20% alum...

Embodiment 1

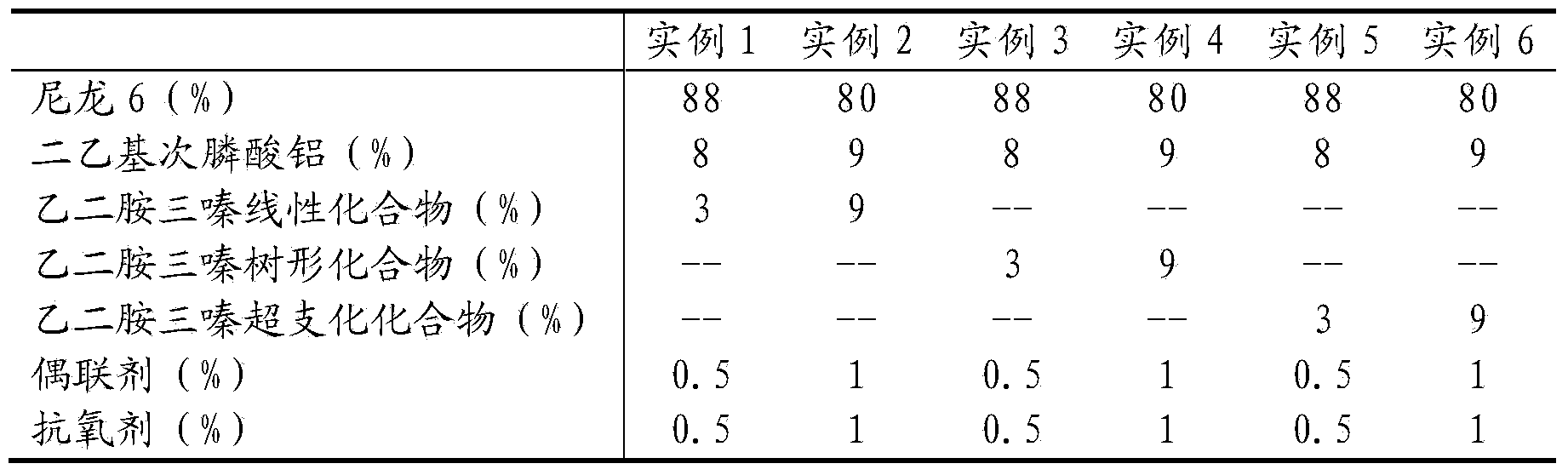

[0046] Mix aluminum diethylphosphinate, ethylenediaminetriazine linear compound, KH550, antioxidant 1010, and nylon 6 in a certain proportion. The content percentage of each component is shown in Table 1. The mixture is melted and blended at 230°C. The LOI of the obtained flame-retardant PA6 is 36.7%, and the vertical combustion of UL 94 passes the V-0 level.

Embodiment 2

[0048] Mix aluminum diethylphosphinate, ethylenediaminetriazine linear compound, KH550, antioxidant CA and nylon 6 in a certain proportion. The content percentage of each component is shown in Table 1. The mixture is melt blended at 240°C. The LOI of the obtained flame-retardant PA6 is 37.3%, and the vertical combustion of UL 94 passes the V-0 level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com