Preparation method of quickly positioned polyurethane sealant

A polyurethane sealant, fast technology, applied in the direction of polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve the problems of waiting for a long time, save process efficiency, unfavorable production costs, etc., to shorten the process interval time, process efficiency, cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

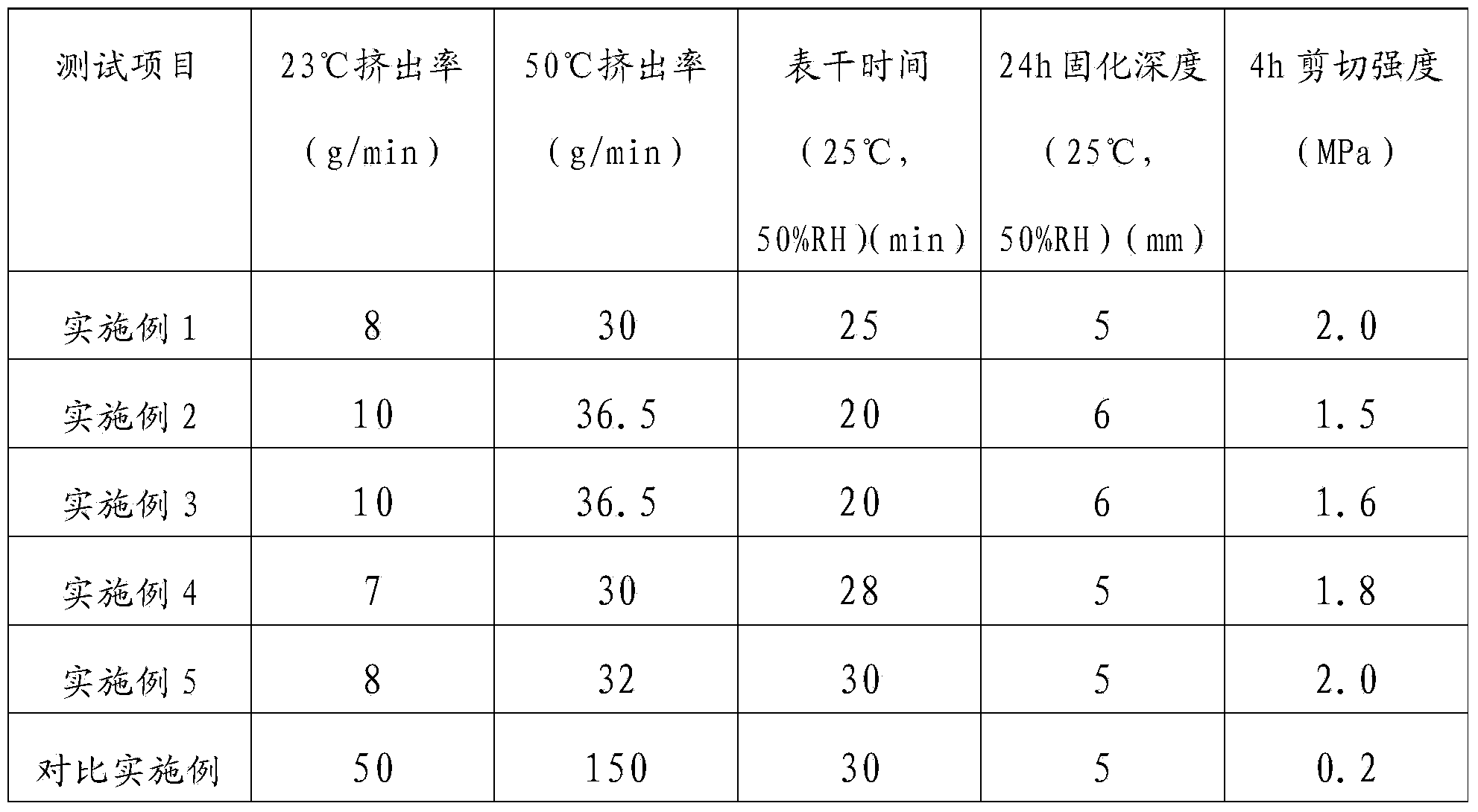

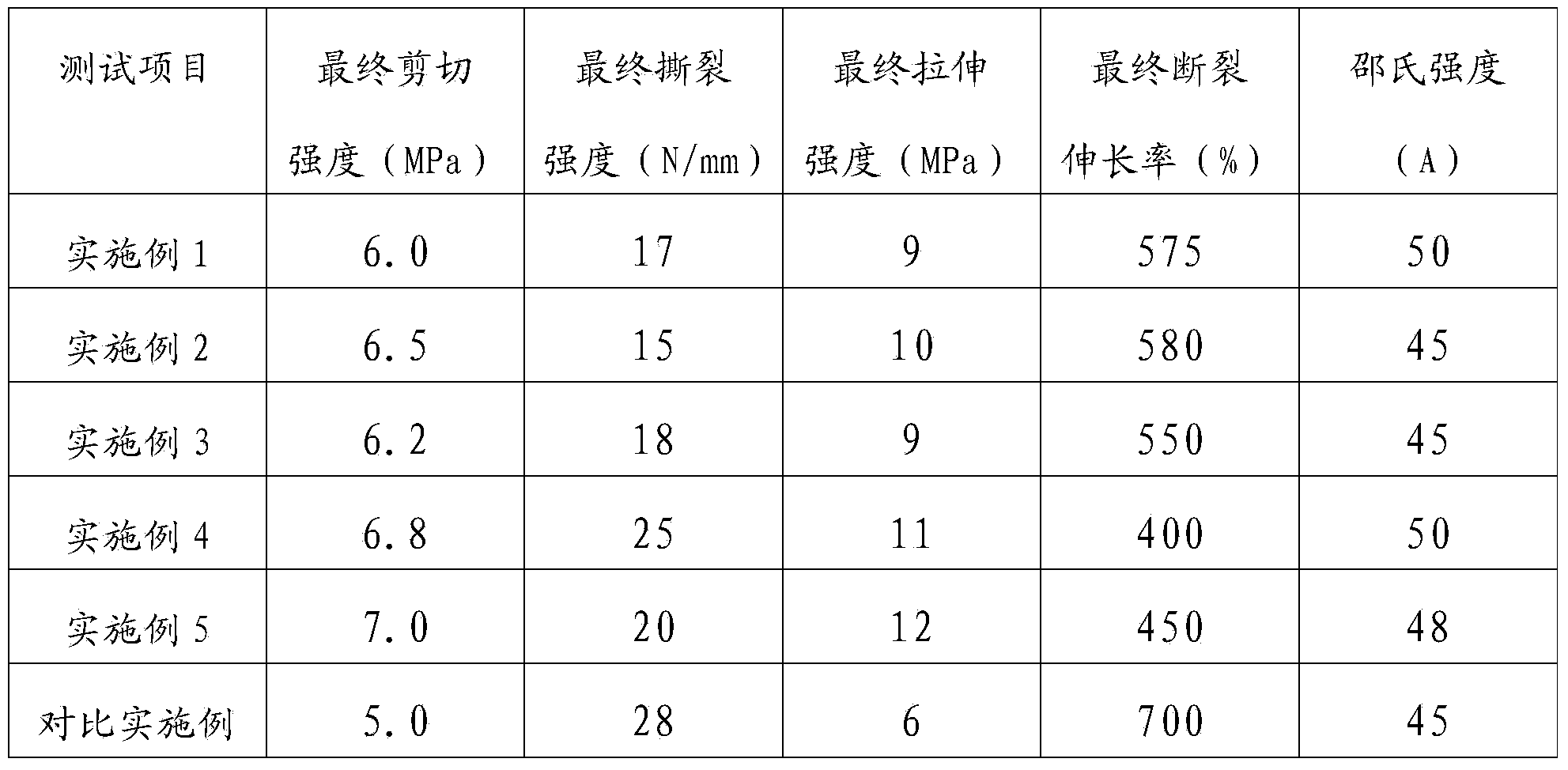

Examples

Embodiment 1

[0023] A method for preparing quick positioning polyurethane sealant, the steps are as follows:

[0024] (1) Take 125kg of polyoxypropylene triol and glycol copolymer with molecular weight of 5000 and 219kg of polyoxypropylene glycol with molecular weight of 4000 to mix and react with 55kg MDI at 85℃ for 3h. The measured NCO endpoint is 2.60%. Prepare prepolymer A for later use; take 80 kg of polyhexylene adipate diol with a molecular weight of 3000 and 88 kg of polybutylene phthalate diol with a molecular weight of 2000 and mix them with 35 kg of MDI at 100°C. 1.5h, the measured NCO endpoint is 2.80%, prepare prepolymer B for use;

[0025] (2) Dehydrate the heavy calcium carbonate and carbon black in an oven at 110°C for 48 hours and keep it heated for standby; detect the water content of the plasticizer DOP and control its water content to be less than 0.05% for standby;

[0026] (3) Add 20kg of plasticizer DOP of step (2), 30kg of prepolymer A and 20kg of prepolymer B of step (1)...

Embodiment 2

[0030] A method for preparing quick positioning polyurethane sealant, the steps are as follows:

[0031] (1) Take 125 kg of polyoxypropylene triol and glycol copolymer with molecular weight of 5000 and 120 kg of polyoxypropylene glycol with molecular weight of 2000 to mix and react with 45kg of MDI at 85°C for 3 hours. The measured NCO endpoint is 2.35%. Prepare prepolymer A for use; take 70 kg of polybutylene adipate diol with molecular weight of 3000 and 88 kg of poly(ethylene phthalate glycol) with molecular weight of 1600 and mix with 35 kg of MDI at 100°C After reacting for 1.5 hours, the NCO end point was measured to be 2.45%, and prepolymer B was prepared for use;

[0032] (2) Dehydrate the light calcium carbonate, carbon black and meteorological silicon powder in an oven at 110°C for 48 hours and keep it heated for standby; detect the water content of the plasticizer DINP and control its water content to less than 0.05% for standby;

[0033] (3) Add 18kg of plasticizer DINP ...

Embodiment 3

[0037] A method for preparing quick positioning polyurethane sealant, the steps are as follows:

[0038] (1) Take 150kg of polyoxypropylene triol and glycol copolymer with a molecular weight of 6000 and 120kg of polyoxypropylene glycol with a molecular weight of 2000, and mix them with 30kg of IPDI at 85°C for 3h. The measured NCO endpoint is 2.80%. Prepare prepolymer A for later use; take 100 kg of polyhexylene sebacate diol with a molecular weight of 4000 and 88 kg of polyethylene phthalate diol with a molecular weight of 1600 and mix with 40 kg of MDI at 100°C Under the conditions, the reaction time is 1.5h, the NCO end point is 2.90%, and the prepolymer B is prepared for use;

[0039] (2) Dehydrate the light calcium carbonate, carbon black and titanium dioxide in an oven at 110°C for 48 hours, and keep it heated for standby; detect the water content of the plasticizer DINP and control its water content to less than 0.05% for standby;

[0040] (3) Add 18kg of plasticizer DINP of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com