IE-grade power cable for third-generation passive nuclear power plant gentle environment and production method

A technology for power cables and nuclear power plants, which is applied to the manufacture of power cables with shielding layers/conductive layers, insulated cables, and cable/conductors. It can solve problems such as fuel usage restrictions, and achieve improved service life, cable life, and overall strength. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

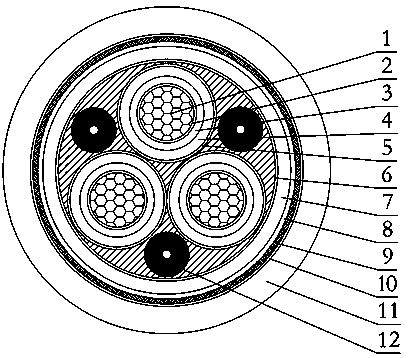

[0031] Reference attached figure 1 , the third-generation passive nuclear power plant mild environment IE grade power cable, including three cores and three filler cores 12, and the axial axis of the cores is arranged in a triangle; the cores include more than one conductor 1, and the outer wall of each conductor 1 is wrapped There is a first wrapping tape 2, and the first wrapping tape 2 is extruded to wrap the inner insulating layer 3 and the outer insulating layer 4 and is wrapped with a second wrapping tape 5; there are three filling cores 12, and the axial axes of the filling cores 12 are Arranged in an inverted triangle; the filler core 12 and the wire core are mutually cut and stranded to form a cable core; the cable core is provided with a tape layer 6, a filling layer 7, an inner shielding layer 8, an outer shielding layer 9, and a wrapping layer 10 in sequence from the inside to the outside. , and sheath layer 11.

[0032] In this embodiment, the filling core includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com