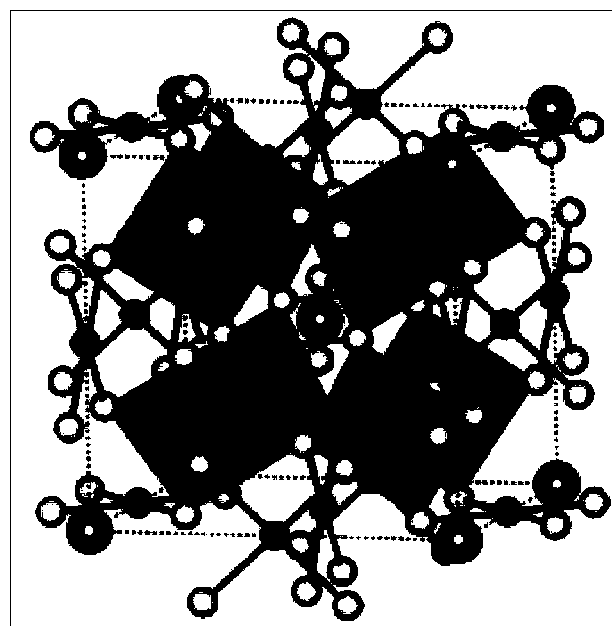

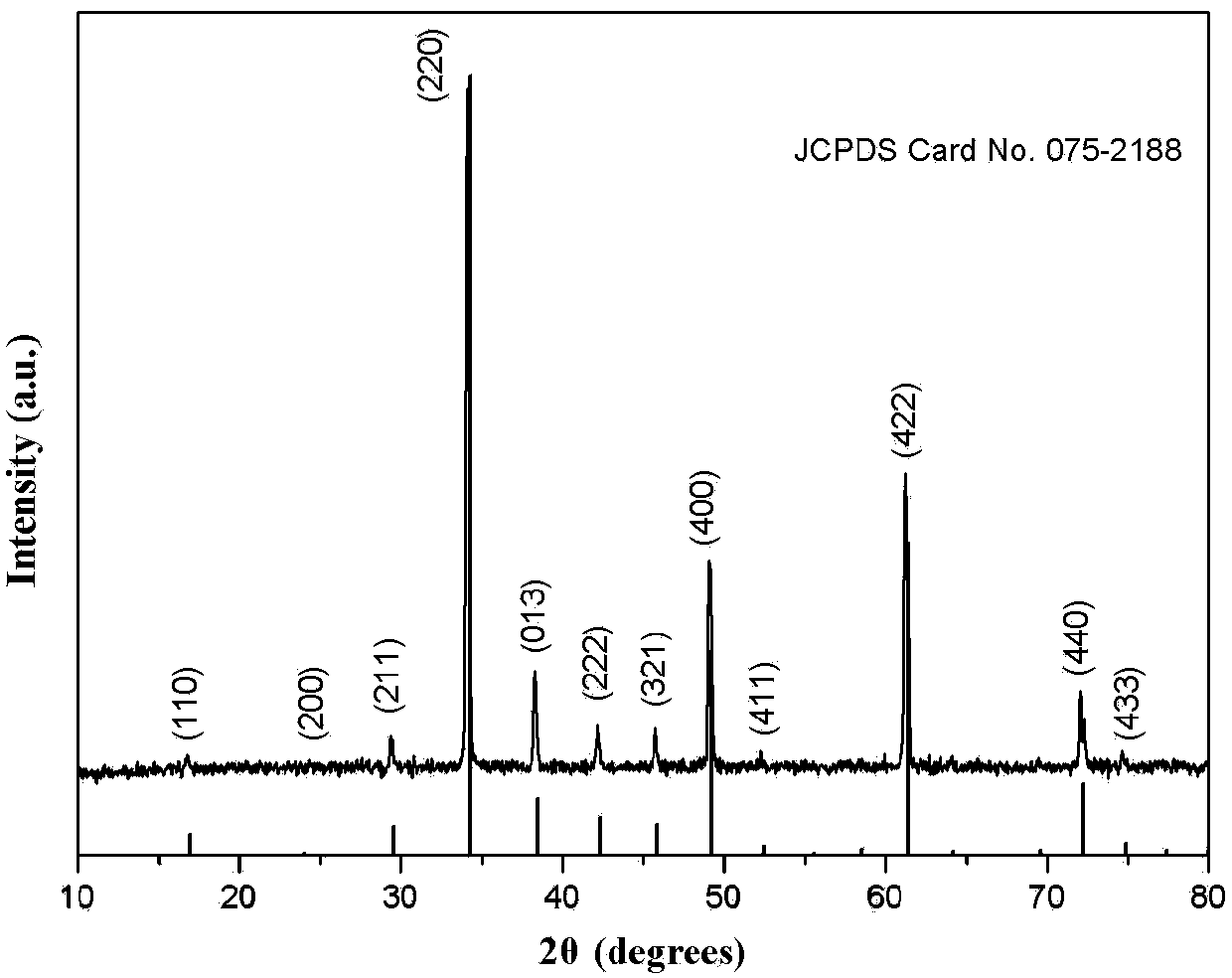

New application and preparation method of copper calcium titanate (CaCu3Ti4O12) (CCTO)

A technology of calcium copper titanate and capacitors, applied in the direction of resistance manufacturing, resistors, electrical components, etc., can solve problems such as limiting the application of CCTO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

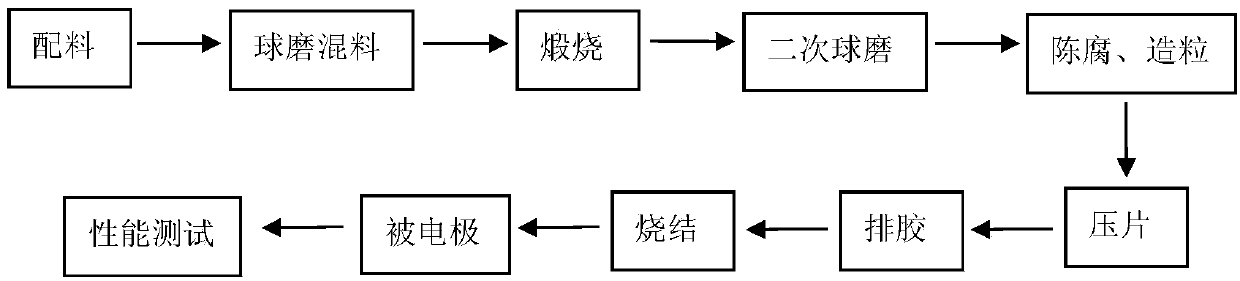

[0030] (1) Accurately weigh 3.04g, 7.25g, and 9.71g of calcium carbonate, copper oxide, and titanium dioxide with a purity greater than 99.5% respectively on a precision electronic balance, and mix the weighed raw materials to obtain a mixture.

[0031] (2) The mixture in (1) was placed in a ball milling tank lined with polytetrafluoroethylene, and ball milling was carried out with deionized water as the ball milling medium at a rotational speed of 250 rpm and a ball milling time of 4 hours. Afterwards, the ball-milled slurry was placed in an oven, and dried at 80° C. for 4 hours to obtain a dry powder.

[0032] (3) Put the dry powder obtained by drying in (2) into a solid-phase reaction furnace, and heat it at 950° C. for 4 hours for calcination to obtain a calcined powder. Afterwards, the powder is subjected to secondary ball milling and drying, the steps are the same as (2), and finally a dried and finely ground powder is obtained.

[0033] (4) Add polyvinyl alcohol soluti...

Embodiment 2

[0046] (1) Accurately weigh 3.04g, 7.25g, and 9.71g of calcium carbonate, copper oxide, and titanium dioxide with a purity greater than 99.5% respectively on a precision electronic balance, and mix the weighed raw materials to obtain a mixture.

[0047] (2) The mixture in (1) was placed in a ball mill tank lined with polytetrafluoroethylene for ball milling, using deionized water as the ball milling medium for ball milling at a rotational speed of 300 rpm and a ball milling time of 4 hours. Afterwards, the ball-milled slurry was placed in an oven, and dried at 80° C. for 4 hours to obtain a dry powder.

[0048] (3) Put the dry powder obtained by drying in (2) into a solid-phase reaction furnace, and heat it at 950° C. for 4 hours for calcination to obtain a calcined powder. Afterwards, the powder is subjected to secondary ball milling and drying, the steps are the same as (2), and finally a dried and finely ground powder is obtained.

[0049] (4) Add polyvinyl alcohol solutio...

Embodiment 3

[0057] (1) Accurately weigh 3.04g, 7.25g, and 9.71g of calcium carbonate, copper oxide, and titanium dioxide with a purity greater than 99.5% respectively on a precision electronic balance, and mix the weighed raw materials to obtain a mixture.

[0058] (2) The mixture in (1) was placed in a ball mill tank lined with polytetrafluoroethylene for ball milling, using deionized water as the ball milling medium for ball milling at a rotational speed of 300 rpm and a ball milling time of 4 hours. Afterwards, the ball-milled slurry was placed in an oven, and dried at a temperature of 80° C. for 6 hours to obtain a dry powder.

[0059] (3) Put the dry powder obtained by drying in (2) into a solid-phase reaction furnace, and heat it at 950° C. for 4 hours for calcination to obtain a calcined powder. Afterwards, the powder is subjected to secondary ball milling and drying, the steps are the same as (2), and finally a dried and finely ground powder is obtained.

[0060] (4) Add polyviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leakage current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com