Construction method and device of traveling wave cavity high-power carbon dioxide laser

A carbon dioxide and laser technology, applied in the field of optical engineering and laser applications, can solve the problems of the large size of the laser, the output power does not meet the requirements, the beam quality limitation, etc., and achieve the effect of good beam quality, good coherence and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

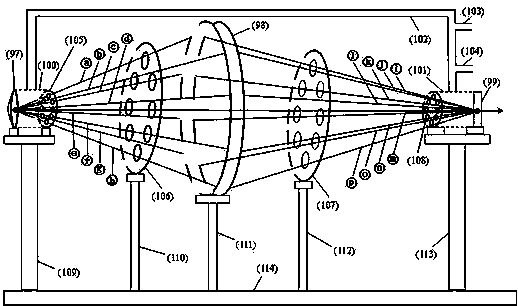

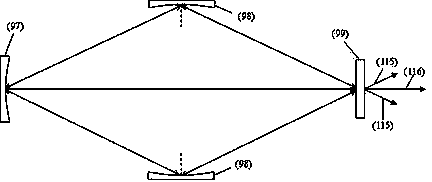

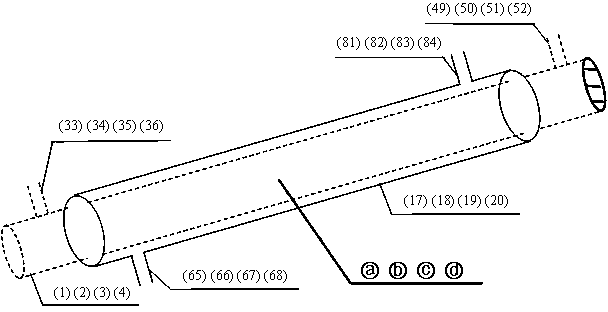

[0029] Example 1, refer to attached Figure 1-6 The length of each discharge tube of the laser is 1 meter, the inner diameter is 10 cm, and the outer diameter is 12 cm. The distance from the positive and negative electrodes to the two ports of the discharge tube is 2 cm. The water-cooled tube is nested outside the discharge tube and kept coaxial with it. , the length is 0.8 meters, the inner diameter is 14 cm, and the outer diameter is 16 cm. According to the attached figure 1 The way shown is placed on the axis of symmetry of the laser. The radius of curvature of the concave mirror is 5 meters, placed on the symmetry axis of the laser, and the distance to the left end of the discharge tube 1-8 is 4 cm, and the radius of curvature of the annular total reflection mirror is 2 meters, placed on the symmetry axis of the laser, to the discharge tube 1-8 The distance from the right end to the left end of the discharge tube 9-16 is 4 cm, and the plane output mirror is placed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com