High Solids Flux Cycle Carbonation Reactor

A technology of reactor and circulating fluidized bed, applied in the field of capturing carbon dioxide CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

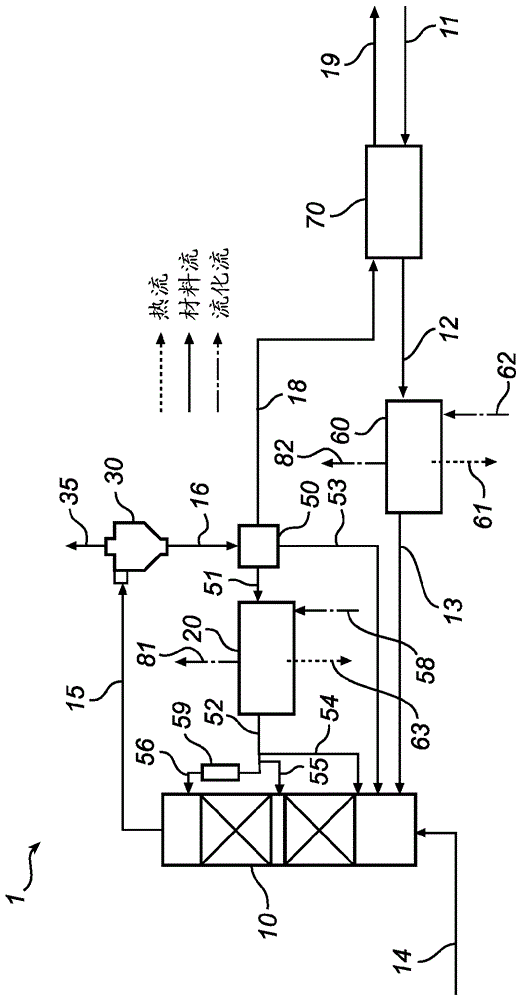

Image

Examples

Embodiment Construction

[0046] The carbonization reaction, that is, the CO in the flue gas according to the following reaction equation 2 and a sorbent material such as selected from metal oxides (MeO) to form MeCO 3 Reaction:

[0047] MeO + CO 2 →MeCO 3 + heat

[0048] The reaction is exothermic and proceeds at a temperature depending on the metal oxide used. Control of temperature is important to ensure an efficient reaction system that balances kinetic and equilibrium requirements. Carbon dioxide CO can occur using different metal oxides MeO that form metal carbonates such as limestone 2 catch. Metal oxides can also be part of synthetic solid particles. The metal oxide used in the present invention can be selected from calcium oxide CaO, magnesium oxide MgO, aluminum oxide Al 2 o 3 , zinc oxide ZnO and calcium magnesium oxide CaMgO, which form calcium carbonate (CaCO 3 ) (for example in the form of calcite or aragonite), magnesium carbonate (MgCO 3 ) (for example in the form of magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com