A fish pond inlet water jet blending device for aquaculture

An aquaculture, fish pond technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of inability to effectively remove carbon dioxide, difficult to obtain pure oxygen, uneven gas distribution, etc., to reduce the water circulation rate and improve oxygen transfer. Efficiency, the effect of improving the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings.

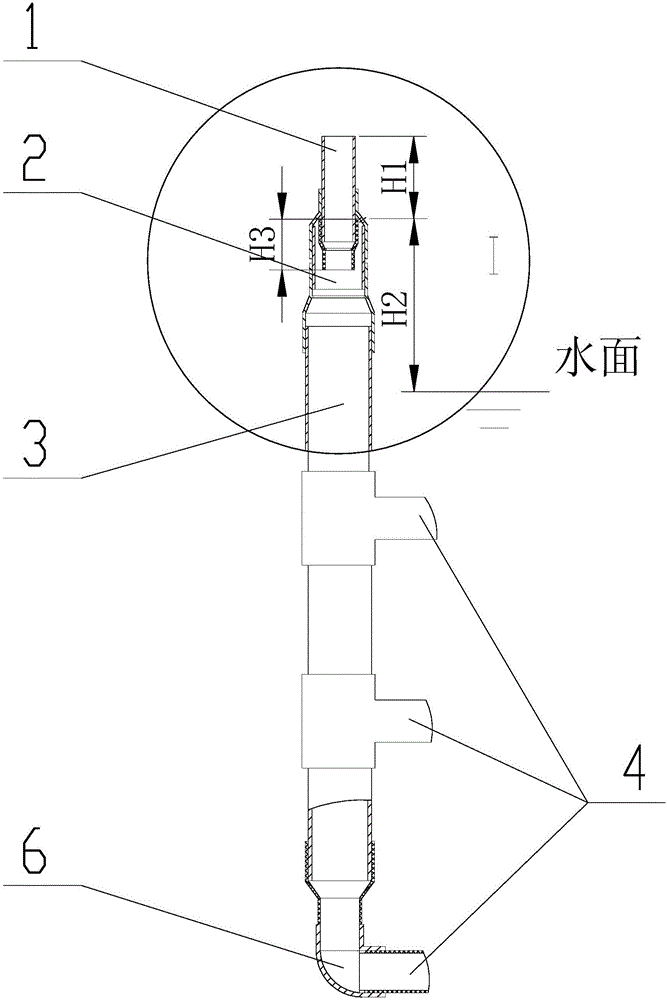

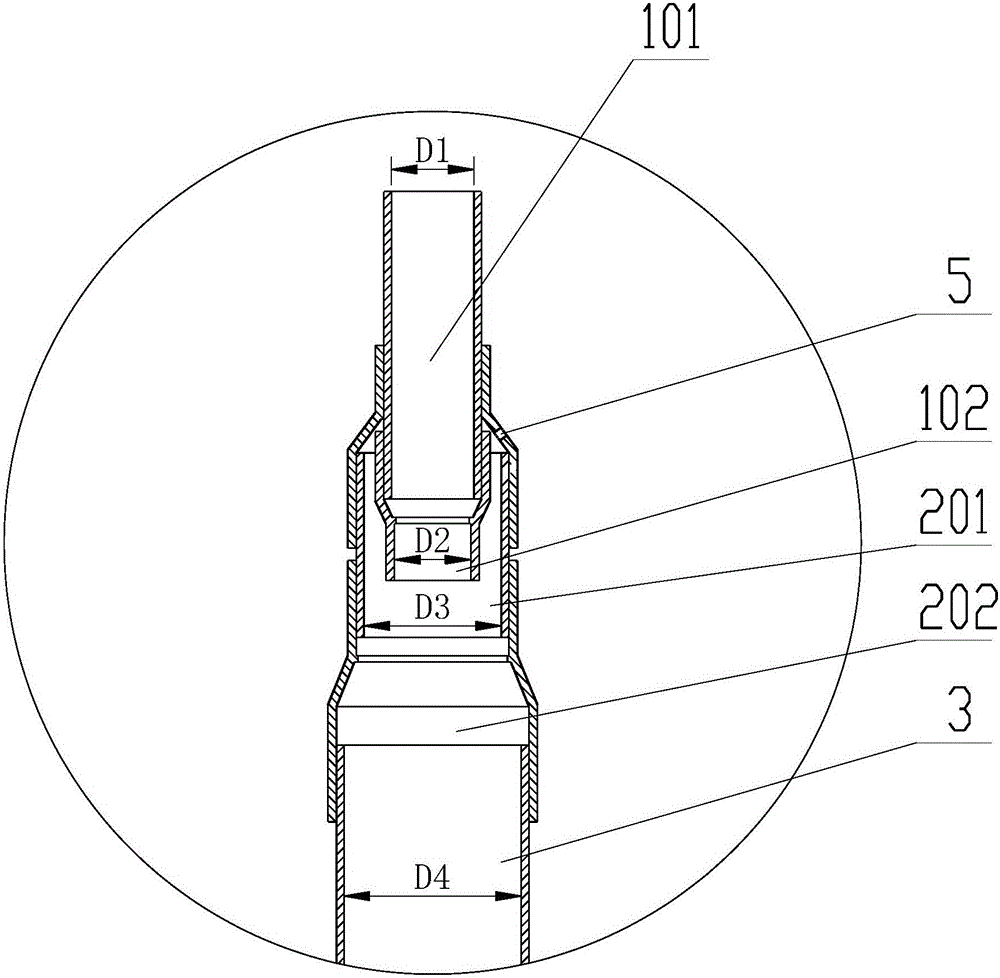

[0038] Figure 1~2 The device includes a pressure water inlet pipe 1, a diffusion pipe 2, a mixing pipe 3, and a water outlet pipe 4 arranged in sequence from above and below. Among them, the pressure water inlet pipe 1, the diffusion pipe 2, and the mixing pipe 3 are arranged vertically, and the outlet pipe 4Horizontal configuration.

[0039] The pressure water inlet pipe 1 is a tapered pipe with a tapered section. The upper end of the pipe body is an inlet area 101 with an inner diameter of D1, and the lower end of the pipe body is tapered downwards to form an outlet area 102 with an inner diameter of D2.

[0040] Diffusion tube 2 is a diverging tube with two diverging sections. The inner diameter of the upper end port of the pipe body corresponds to the outer diameter of the lower end port of the pressure water inlet pipe 1. After the upper end is gradually expanded downwards, a diffu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com