A kind of garbage transfer station deodorant and preparation method thereof

A technology for waste transfer station and deodorant, which is applied in separation methods, chemical instruments and methods, energy and wastewater treatment, etc. Efficient deodorization effect and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

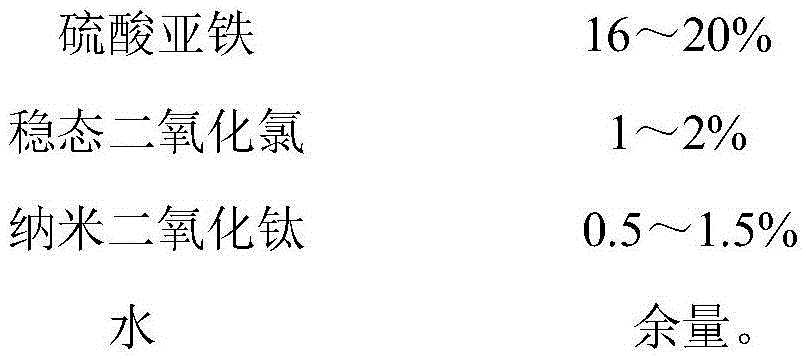

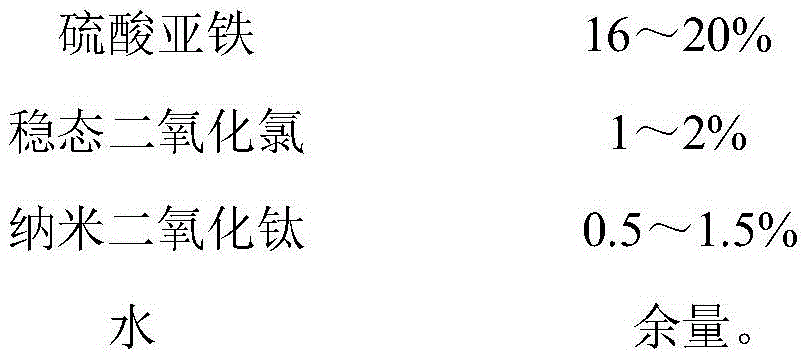

Embodiment 1

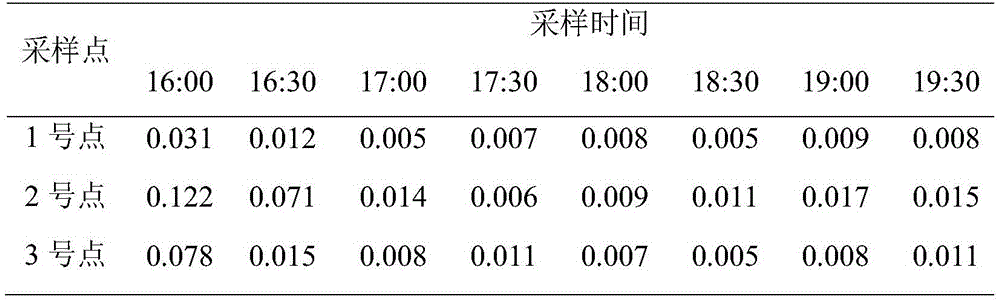

[0027] On-site deodorization test was carried out at a garbage transfer station in Nanjing. Firstly, a pool with a serious rancid smell and a lot of acid gases such as hydrogen sulfide was selected, and the mixed solution A and the mixed solution B were mixed according to the mass ratio A:B=1:1.5. Dilute the mixture 10 times with water, stir evenly, and then spray it in the garbage pool. The mass percentage of each component is: 1% of steady-state chlorine dioxide; 20% of ferrous sulfate; 0.5% of nano titanium dioxide; and the balance of water.

[0028] (1) Preparation of mixed solution A and mixed solution B:

[0029] Put 500g of water into a conical flask, first add 25g of steady-state chlorine dioxide, stir until completely dissolved, and obtain a yellow-green clear solution. Then add 5g of nano-titanium dioxide in batches, continue to stir, and the solution becomes a light yellow milky emulsion, which is designated as mixed solution A. Add 200g of water to another Erlenm...

Embodiment 2

[0038] In a garbage transfer station in Nanjing, a pond with a serious irritating stench was selected, and the ability of the deodorant to remove ammonia was mainly investigated. Mixed solution A and mixed solution B are mixed according to the mass ratio A:B=1:0.5, the mixed solution is diluted 10 times with water, and sprayed in the garbage compression pool. The mass percentage of each component is: steady state chlorine dioxide 1%; ferrous sulfate 20%; nano-titanium dioxide 0.5%; the balance water.

[0039] The implementation method of this embodiment includes the preparation of the mixed solution A and the mixed solution B, the mixing, dilution and spraying of the original solution, and the detection of the deodorizing effect. Concrete operation method is with embodiment 1. SKY2000-NH 3 The data obtained by the type pump-suction ammonia detector shows that the deodorant prepared according to this method not only deodorizes thoroughly, but also reduces the odor concentrati...

Embodiment 3

[0041] In a waste transfer station in Nanjing, a pond with both putrid and foul odors was selected, and a comprehensive deodorization test was carried out on it. The mixed solution A and the mixed solution B are mixed according to the mass ratio A:B=1:1, the mixed solution is diluted 10 times with water, and sprayed on the garbage transfer station with a lot of mixed gases containing sulfur and nitrogen. The mass percentage of each component is: steady state Chlorine dioxide 1%; ferrous sulfate 20%; nanometer titanium dioxide 0.5%; balance water.

[0042] The implementation method of this embodiment includes the preparation of the mixed solution A and the mixed solution B, the mixing, dilution and spraying of the original solution, and the detection of the deodorizing effect. Concrete operation method is with embodiment 1. H on the scene 2 S, NH 3 Concentration testing, the results show that the deodorant can minimize the odor content, deodorization time can be maintained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com