Multi-effect decompression membrane distillation method and device thereof

A multi-effect membrane distillation and membrane distillation technology, which is applied in the field of decompression multi-effect membrane distillation methods and devices thereof, can solve the problems of low membrane distillation flux and the like, and achieve high membrane distillation flux, low energy consumption and high heat recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

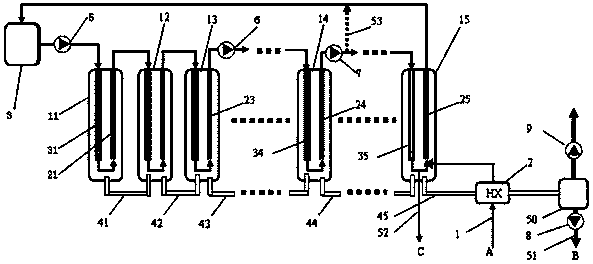

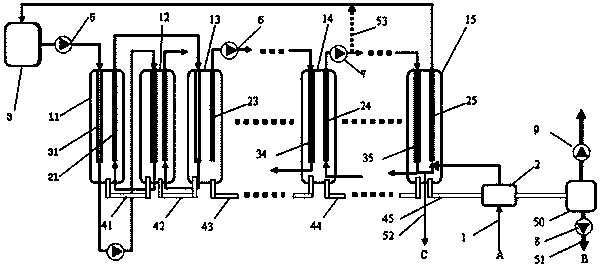

[0038] In the multi-effect membrane distillation method proposed by the present invention, multi-stage membrane distillation combination elements can be provided according to actual needs, but at least two stages are required. The following will be described according to the schematic diagram of the process flow of the multi-effect membrane distillation device of the present invention. figure 1 , figure 2 Both are schematic diagrams of the process flow of the multi-effect membrane distillation device of the present invention, and the pipeline connections of the two are slightly different.

[0039] Such as figure 1 As shown, the feed liquid coming out of the circulating heating water tank 3 has a temperature of 60 to 95°C, and is sent to the hydrophobic membrane flow path in the first-stage membrane distillation assembly element 11 through the circulating water pump 5, and flows through the hydrophobic membrane from top to bottom. The flow path 31, under the negative pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com