A kind of preparation method and application of polypropylene hollow fiber hydrophobic membrane

A polypropylene and hydrophobic membrane technology, applied in the field of material science, can solve the problems of low membrane distillation flux and unstable rejection rate, so as to improve membrane distillation flux, gasification efficiency and membrane distillation flux, and improve gas The effect of chemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

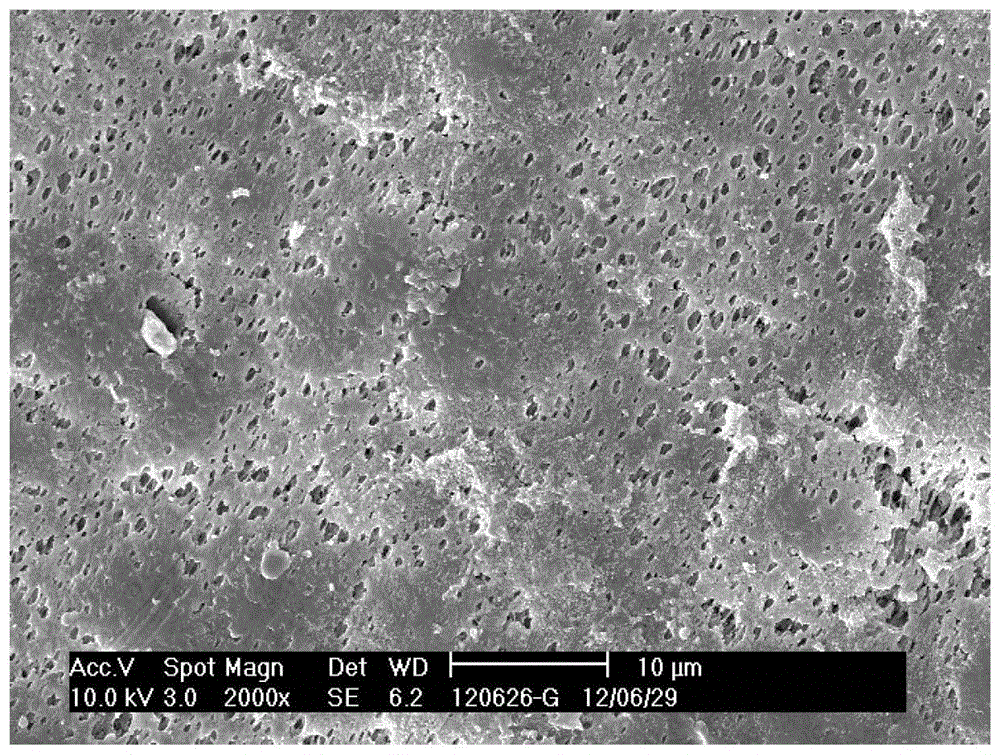

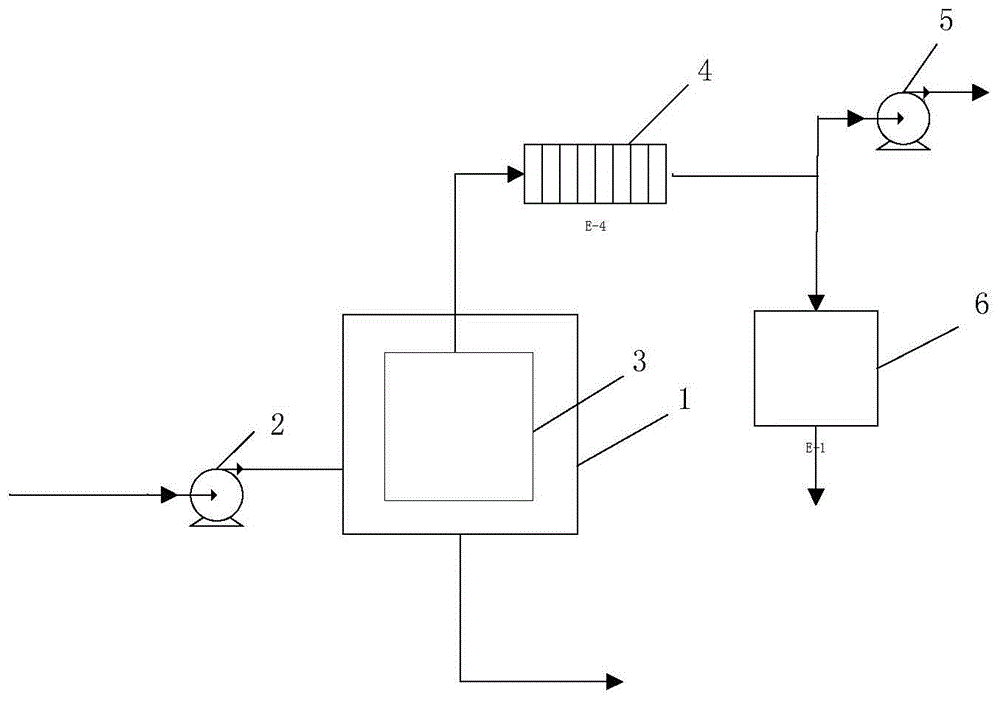

Image

Examples

preparation example 1

[0052] A method for preparing a polypropylene hollow fiber hydrophobic membrane for external pressure vacuum membrane distillation, the specific steps are as follows:

[0053] (1) Add polypropylene resin, diluent and additives in the spinning kettle with stirring device, the mass percentage of polypropylene resin is 18%, and melt index is 2g / 10min, with soybean oil and dibutyl phthalate The mixture of grease is diluent, the mass percentage of dibutyl phthalate in the mixture is 90%, the mass percentage of diluent is 73%, the additive is adipic acid, and the addition amount is 0.1% of the polypropylene resin mass, heated to 175°C, and stirred for 3 hours under the condition of nitrogen flow, stopped the stirring and stood for defoaming for 1 hour to obtain the casting solution;

[0054] (2) Use a metering pump to transport the casting liquid to the spinneret, and introduce soybean oil with a temperature of 60°C as an internal solidification medium into the spinneret to form a h...

preparation example 2

[0066] A method for preparing a polypropylene hollow fiber hydrophobic membrane for external pressure vacuum membrane distillation, the specific steps are as follows:

[0067] (1) Add polypropylene resin, diluent and additives to the spinning kettle with stirring device. The mass percentage of polypropylene resin is 30%, and the melt index is 3.1g / 10min. The mixture of octyl fat is a diluent, the mass percentage of dioctyl phthalate in the mixture is 50%, the mass percentage of diluent is 70%, the additive is WBG, and the addition amount is 0.8% of the polypropylene resin mass, heated to 200 ℃, and stirred for 0.5 hours under the condition of blowing nitrogen, stopped the stirring and left to defoam for 0.5 hours to obtain the casting solution;

[0068] (2) Use a metering pump to transport the casting solution to the spinneret, and introduce dioctyl phthalate at a temperature of 30°C into the spinneret as an internal solidification medium to form a hollow fiber membrane. 180°...

preparation example 3

[0080] A method for preparing a polypropylene hollow fiber hydrophobic membrane for external pressure vacuum membrane distillation, the specific steps are as follows:

[0081] (1) Add polypropylene resin, diluent and additives to the spinning kettle with stirring device, the mass percentage of polypropylene resin is 33%, the melt index is 5g / 10min, dibutyl phthalate is used as diluent Thinner, the mass percentage of diluent is 70%, the additive is benzoic acid, the addition amount is 1% of the weight of polypropylene resin, heated to 180 ℃, and stirred for 1 hour under the condition of nitrogen flow, after stopping the stirring, let it stand for defoaming for 2 hour, obtain casting solution;

[0082] (2) Use a metering pump to transport the casting solution to the spinneret, and introduce a mixture of soybean oil and dibutyl phthalate at a temperature of 90°C into the spinneret as an internal coagulation medium to form a hollow fiber membrane, Wherein the mass percent of soyb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com