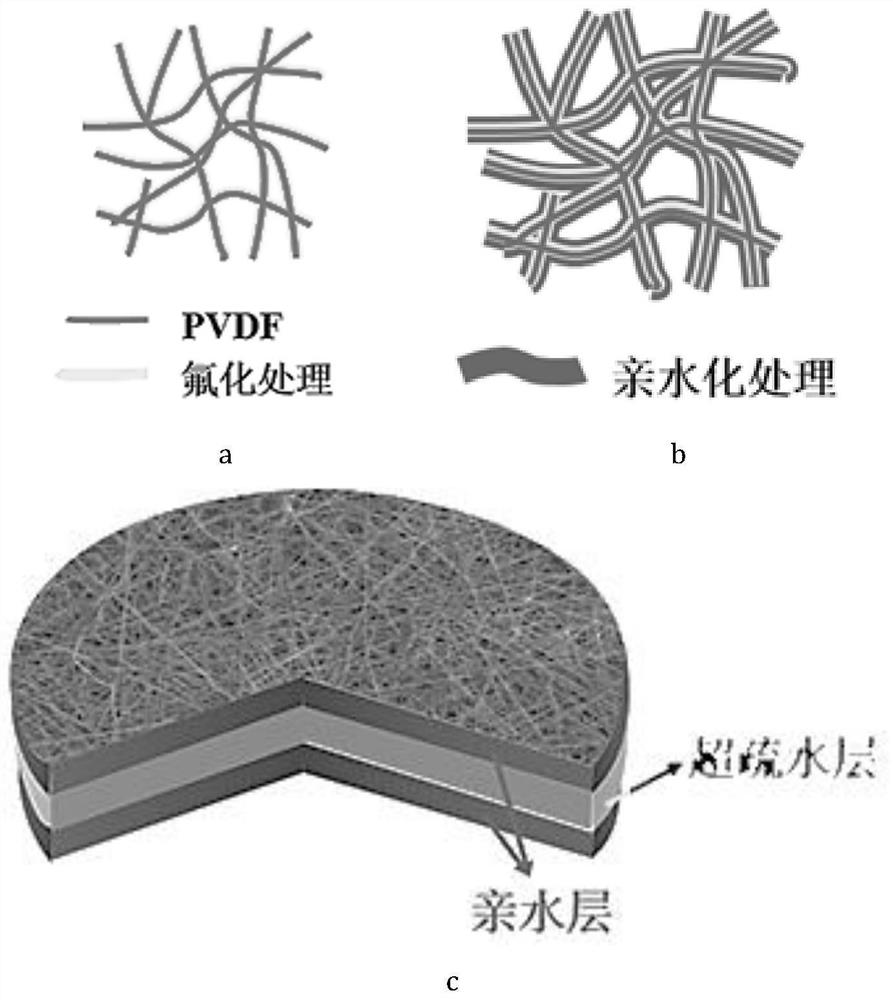

Preparation method of superhydrophobic and double-sided hydrophilic electrospun nanofiber composite membrane

A nanofiber and electrospinning technology is applied in the field of preparation of super-hydrophobic and double-sided hydrophilic electrospinning nanofiber composite membranes, which can solve the problems of membrane wetting and pollution, improve the service life of membranes, reduce membrane pollution, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

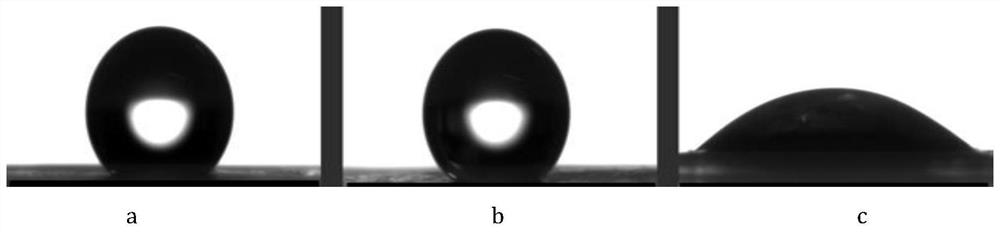

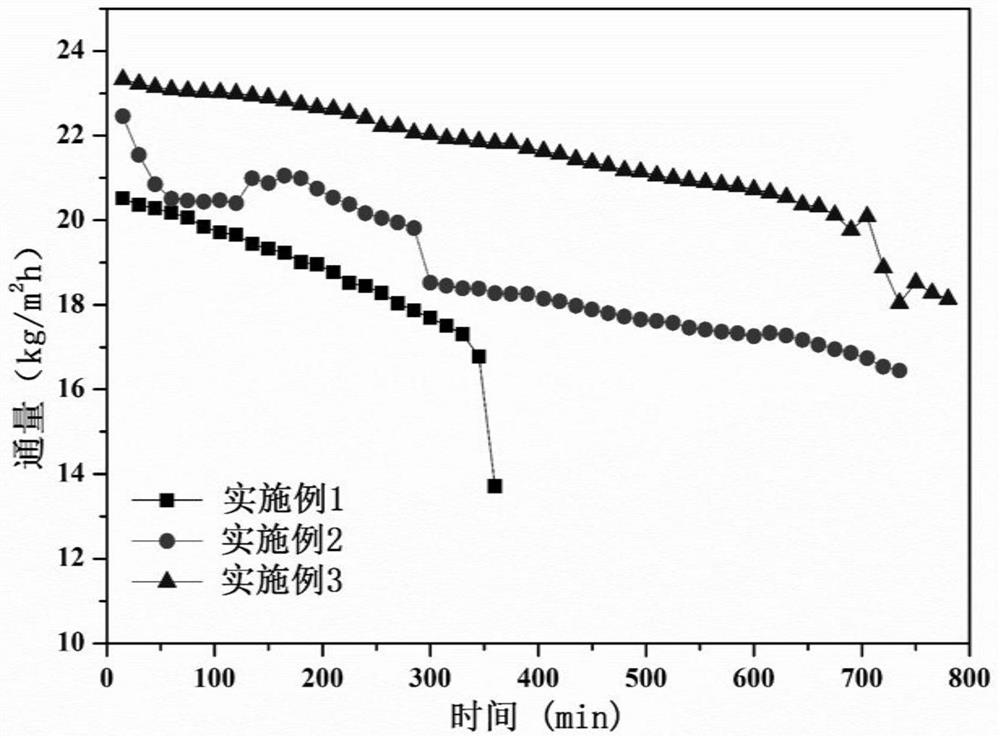

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] 1. Weigh 1.6g of PVDF, N,N-dimethylacetamide, and acetone in a three-necked round-bottomed flask, and mechanically stir in a water bath at 50°C for 12 hours until the solid powder is completely dissolved to prepare an electrospinning solution; then The spinning solution was defoamed at 50°C for 2 hours.

[0030] 2. Pour the above spinning liquid into a 10mL syringe in the electrospinning equipment (purchased from Beijing Yongkang Leye Technology Development Co., Ltd.), electrospun the nanofiber membrane with aluminum foil as the receiving substrate, and placed the membrane on the Volatilize the solvent in an oven, wherein: the electrospinning parameters are: spinning solution temperature 25°C, air humidity 60%, spinning solution injection rate 0.08mm / min, spinning positive voltage 16kV, negative voltage -1kV, The distance from the syringe needle to the receiving drum was 15 cm, and the rotating speed of the drum wa...

Embodiment 2

[0032] This embodiment includes the following steps:

[0033] 1. Weigh 1.6g of PVDF, N,N-dimethylacetamide, and acetone in a three-necked round-bottomed flask, and mechanically stir in a water bath at 50°C for 12 hours until the solid powder is completely dissolved to prepare an electrospinning solution; then The spinning solution was defoamed at 50°C for 2 hours.

[0034] 2. Pour the above spinning liquid into a 10mL syringe in the electrospinning equipment (purchased from Beijing Yongkang Leye Technology Development Co., Ltd.), electrospun the nanofiber membrane with aluminum foil as the receiving substrate, and placed the membrane on the Volatilize the solvent in an oven, wherein: the electrospinning parameters are: spinning solution temperature 25°C, air humidity 60%, spinning solution injection rate 0.08mm / min, spinning positive voltage 16kV, negative voltage -1kV, The distance from the syringe needle to the receiving drum was 15 cm, and the rotating speed of the drum wa...

Embodiment 3

[0037] This embodiment includes the following steps:

[0038] 1. Weigh 1.6g of PVDF, N,N-dimethylacetamide, and acetone in a three-necked round-bottomed flask, and mechanically stir in a water bath at 50°C for 12 hours until the solid powder is completely dissolved to prepare an electrospinning solution; then The spinning solution was defoamed at 50°C for 2 hours.

[0039] 2. Pour the above spinning solution into a 10mL syringe in the electrospinning equipment (purchased from Beijing Yongkang Leye Technology Development Co., Ltd.), and electrospun the nanofiber membrane with aluminum foil as the receiving substrate. The solvent was volatilized in an oven, wherein: the electrospinning parameters were: spinning solution temperature 25°C, air humidity 60%, spinning solution injection rate 0.08mm / min, spinning positive voltage 16kV, negative voltage -1kV, The distance from the syringe needle to the receiving drum was 15 cm, and the rotating speed of the drum was 100 rpm.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com