A kind of decompression multi-effect membrane distillation method and its device

A multi-effect membrane distillation and membrane distillation technology, which is applied in chemical instruments and methods, membrane technology, total evaporation, etc., can solve the problems of high energy consumption and achieve the effects of low energy consumption, reduced consumption, and high heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

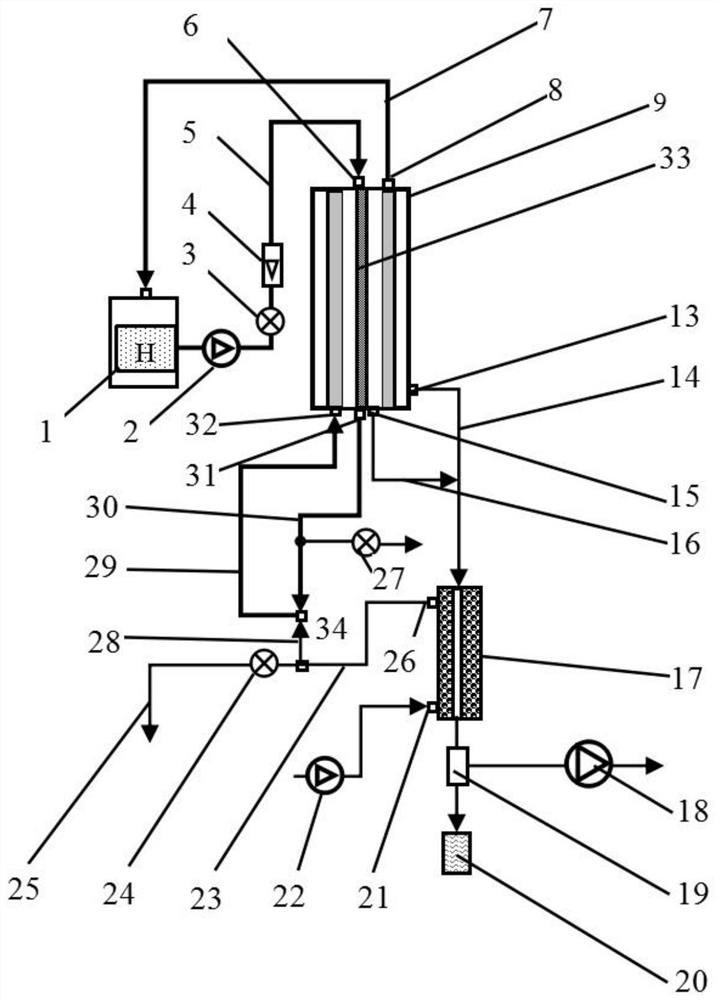

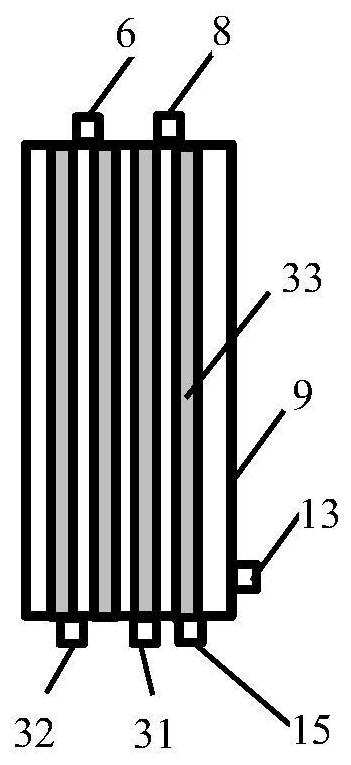

[0032] A vacuum multi-effect membrane distillation device, such as figure 1 As shown, it includes a plurality of membrane distillation components, circulating water pump 2, vacuum pump 18, hot feed liquid circulating heating device 1, heat exchanger 17, raw water centrifugal pump 22, gas-liquid separator 19, valves and connecting pipes between them .

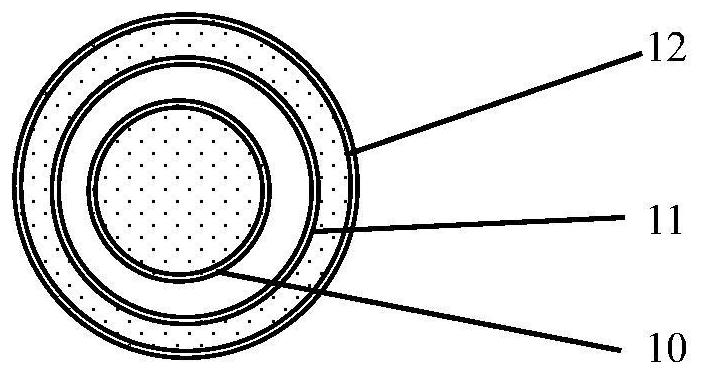

[0033] A plurality of membrane distillation combination units 33 are installed side by side in the housing 9 to form a membrane distillation combination element, such as image 3 , the centermost part of each membrane distillation combination unit 33 is the inner layer hydrophobic membrane 10 of the vertical flow path from top to bottom, the outer surface of which is the tubular heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com