Low-temperature denitration and synergetic desulfurization active carbon catalyst and preparation method thereof

A low-temperature denitration and activated carbon technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of the decrease of denitration efficiency and the influence of modified activated carbon denitration efficiency, etc., to improve the desulfurization and denitration function and reduce the operation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

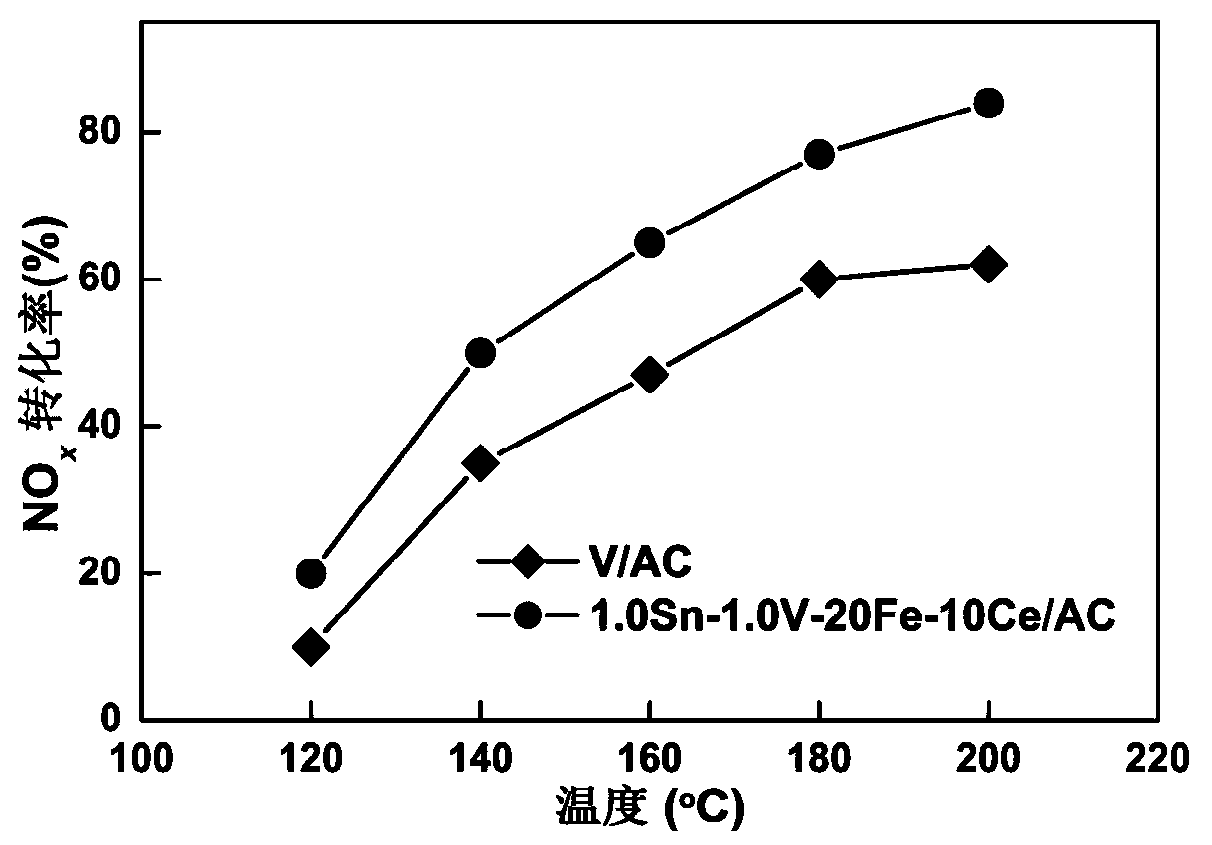

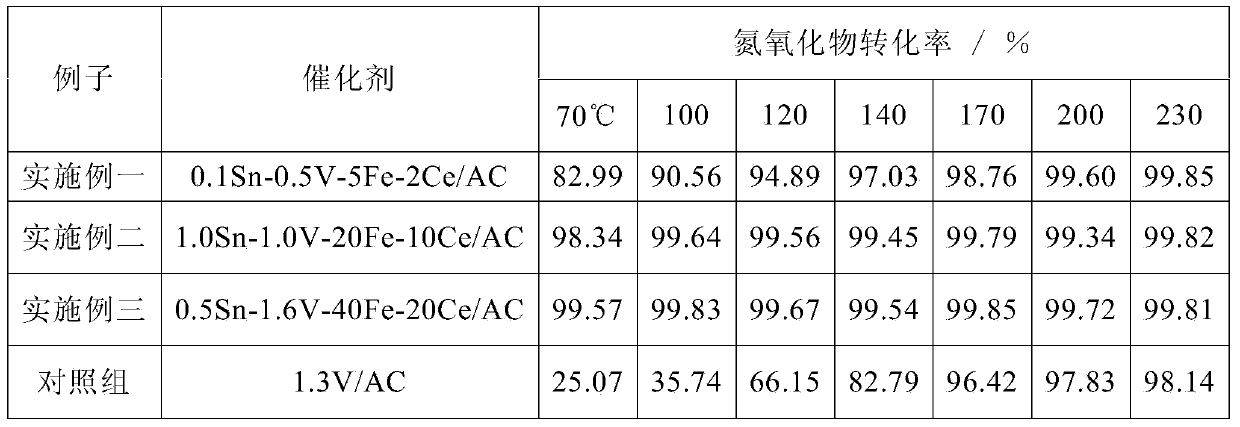

[0020] a SnCl 4 and V 2 o 5 as the active component, with activated carbon as the carrier, with Fe 2 o 3 and CeO 2 It is a desulfurization and denitrification catalyst as an auxiliary agent, and its raw material components are: tin chloride with a content of 0.1% of the mass of activated carbon, ammonium metavanadate with a content of 0.5% of the mass of activated carbon, iron nitrate with a content of 5.0% of the mass of activated carbon, The content is 2.0% cerium nitrate of activated carbon mass.

[0021] Its preparation process comprises the following steps:

[0022] Step 1. Weigh a certain amount of activated carbon, soak it in water for 2 hours, and wash it three to five times to remove surface impurities;

[0023] Step 2, dissolving tin chloride, ammonium metavanadate, ferric nitrate and cerium nitrate in water with 10 times the mass sum of the four at room temperature, adding oxalic acid with 3 times the mass of ammonium metavanadate as a cosolvent, stirring to f...

Embodiment 2

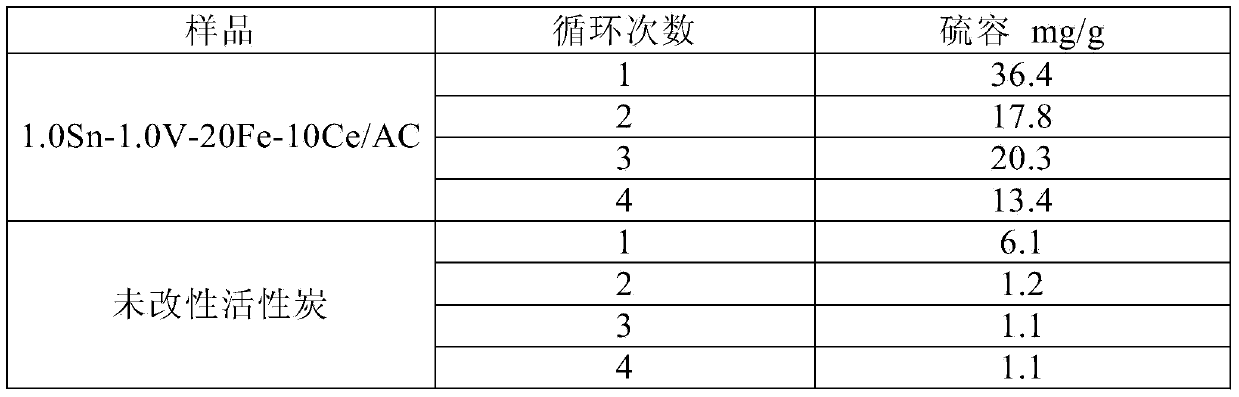

[0030] a SnCl 4 and V 2 o 5 as the active component, with activated carbon as the carrier, with Fe 2 o 3 and CeO 2 It is a desulfurization and denitrification catalyst as an auxiliary agent, and its raw material components are: tin chloride with a content of 1.0% of the mass of activated carbon, ammonium metavanadate with a content of 1.0% of the mass of activated carbon, iron nitrate with a content of 20.0% of the mass of activated carbon, The content is 10.0% cerium nitrate of activated carbon mass.

[0031] Its preparation process comprises the following steps:

[0032] Step 1. Weigh a certain amount of activated carbon, soak it in water for 2 hours, and wash it three to five times to remove surface impurities;

[0033] Step 2, dissolving tin chloride, ammonium metavanadate, iron nitrate and cerium nitrate in water with 15 times the mass sum of the four at room temperature, adding oxalic acid with 3 times the mass of ammonium metavanadate as a cosolvent, stirring to for...

Embodiment 3

[0040] a SnCl 4 and V 2 o 5 as the active component, with activated carbon as the carrier, with Fe 2 o 3 and CeO 2 It is a desulfurization and denitrification catalyst as an auxiliary agent, and its raw material components are: tin chloride with a content of 0.5% of the mass of activated carbon, ammonium metavanadate with a content of 1.6% of the mass of activated carbon, iron nitrate with a content of 40.0% of the mass of activated carbon, The content is 20.0% cerium nitrate of activated carbon mass.

[0041] Its preparation process comprises the following steps:

[0042] Step 1. Weigh a certain amount of activated carbon, soak it in water for 2 hours, and wash it three to five times to remove surface impurities;

[0043] Step 2. Dissolve tin chloride, ammonium metavanadate, iron nitrate and cerium nitrate in water at room temperature that is 20 times the mass of the four, add oxalic acid that is 3 times the mass of ammonium metavanadate as a cosolvent, and stir to form...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap