A tar wastewater purification device capable of producing asphalt

A technology for wastewater purification and tar, which is applied in chemical processing of tar pitch/petroleum pitch/natural pitch, chemical instruments and methods, multi-stage treatment of water/sewage, etc. Problems such as difficulty in further removal of phenols

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

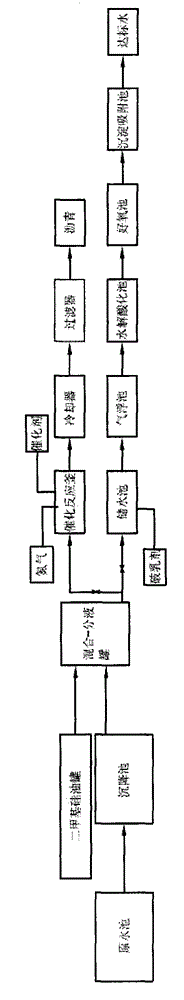

[0019] The tar waste water purifying device that can produce asphalt of the present invention comprises, raw water tank and settling tank, the outlet of described raw water tank is connected with the inlet of settling tank; Dimethicone tank and mixing-separation tank, described The liquid inlet of the mixing-separating tank is connected with the liquid outlet of the settling tank, and the oil inlet of the mixing-separating tank is connected with the outlet of the simethicone tank; in the mixing-separating tank The stirring paddle that can be opened and closed is provided, and the stirring paddle is opened, and the mixing-separating tank is used for mixing simethicone and water, and the stirring paddle is closed, and the mixing-separating tank is used to form the upper dimethicone after standing base silicone oil area and the water area of the lower part; a water storage tank, a catalytic reactor with a reaction temperature of 180-300 ° C and a catalyst tank for storing alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com