Treatment method for acid pickling water and neutralized waste water in tetrabromobisphenol A producing process

A tetrabromobisphenol and treatment method technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of limitation, incomplete oxidation, easy carbon deposition, etc. Achieve the effects of improving water production efficiency, realizing salt recycling, and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

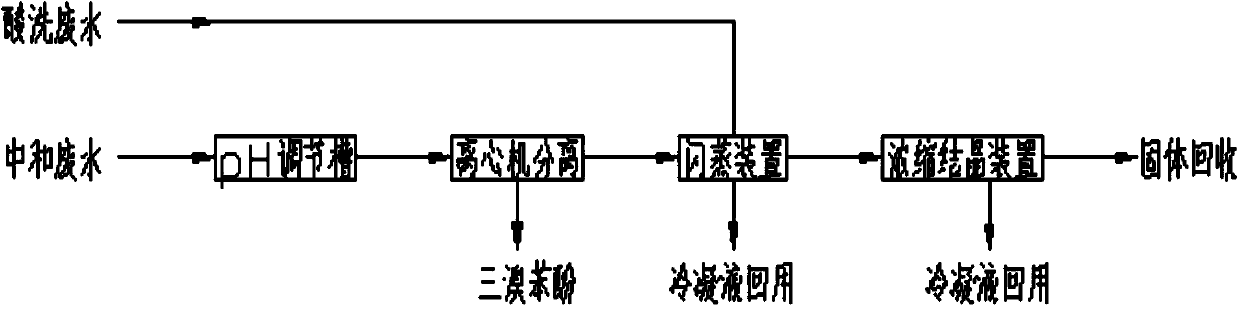

[0031] Embodiment 1: Neutralize wastewater treatment

[0032] Use sulfuric acid to adjust the pH of the neutralized wastewater to 1.5 to form tribromophenol precipitates. After adding polyacrylamide flocculant for treatment, use a centrifuge to separate tribromophenol. The separated clear liquid is heated to 60°C and flashed at -0.09MPa Steam and flash evaporate 10% condensate, and the residual liquid is concentrated and crystallized by steam heating, and the crystalline solid is recovered.

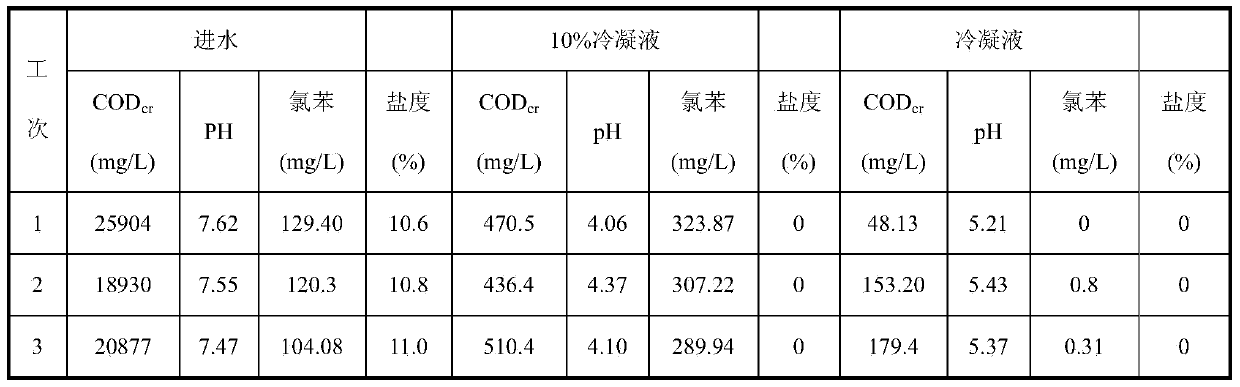

[0033] According to the above experimental parameters, the experimental conditions are shown in Table 2.

[0034] Table 2: Water quality of neutralized wastewater treatment

[0035]

[0036] As can be seen from the experimental results in Table 2, the concentration of chlorobenzene in the flash 10% condensate is 436.4 to 510.4 mg / L, the salinity is 0, and the 10% condensate can be recycled; the concentration of chlorobenzene in the condensate is 0 ~0.8mg / L, the salinity is 0, and the...

Embodiment 2

[0037] Embodiment 2: pickling wastewater treatment

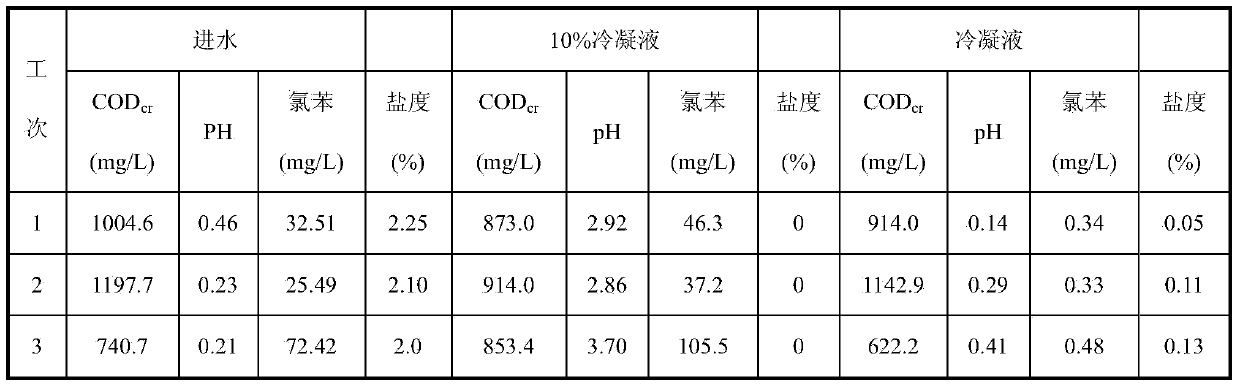

[0038] The pickling waste water directly enters the flash evaporation device, and is flashed at 80°C and -0.09MPa to produce 10% condensate, and the residual liquid vapor is heated to concentrate and crystallize, and the crystalline solid is recovered. According to the above experimental parameters, the experimental conditions are shown in Table 3.

[0039] Table 3: Water quality of pickling wastewater treatment

[0040]

[0041] As can be seen from the experimental results in Table 3, the concentration of chlorobenzene in the flash 10% condensate is 37.16 to 105.5 mg / L, the salinity is 0, and the 10% condensate is recycled; the concentration of chlorobenzene in the condensate is between 0.34 and 0.48mg / L, the salinity is 0.05~0.13mg / L,

[0042] Condensate can also be recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com