modeling paste for painting

A molding paste and painting technology, which is applied in the field of art painting coatings, can solve the problems of not meeting the requirements of environmental protection, poor product performance, and not being able to cater to painters, etc., and achieve excellent adhesion and fluidity, good whiteness, and good plasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

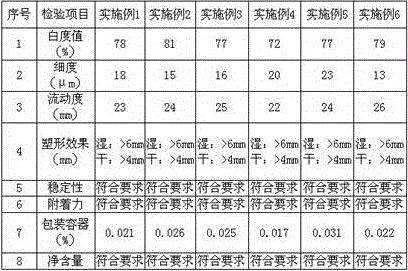

Examples

Embodiment 1

[0023] Select the following components by weight ratio: acrylate emulsion: 20 parts; propylene glycol: 10 parts; rutile titanium dioxide: 14 parts; gypsum powder: 23 parts; talcum powder: 13 parts; cellulose ether: 3 parts; -2-methyl-4-isothiazolin-3-one: 2 parts; anti-yellowing agent: 1 part; phosphate: 1 part, non-ionic polyurethane associative modifier: 1 part, alkali-swellable emulsion type Leveling agent: 1 part, disodium cocoyl monoethanolamide sulfosuccinate: 1 part, phosphate defoamer: 1 part, disodium cocoyl monoethanolamide sulfosuccinate: 1 part; water: 8 parts.

[0024] Add the above components into a high-speed disperser and stir for 10 minutes, then continue to stir for 10 minutes after cooling, and obtain the molding paste for painting after cooling.

Embodiment 2

[0026] Select the following components by weight ratio: acrylate emulsion: 25 parts; glycerol: 4 parts; rutile titanium dioxide: 17 parts; gypsum powder: 25 parts; talcum powder: 15 parts; -Chloro-2-methyl-4-isothiazolin-3-one: 2 parts; anti-yellowing agent: 0.8 part; silicate: 0.7 part, nonionic polyurethane associative modifier 0.8 part, alkali swelling 0.8 parts of emulsion type leveling agent, 0.9 parts of phosphate defoamer, 1 part of disodium coco monoethanolamide sulfosuccinate monoester; water: 5 parts.

[0027] Add the above components into a high-speed disperser and stir for 10 minutes, then continue to stir for 10 minutes after cooling, and obtain the molding paste for painting after cooling.

Embodiment 3

[0029] Select the following components according to the weight ratio: acrylate emulsion: 28 parts; butyl glycol ether: 10 parts; rutile titanium dioxide: 13 parts; gypsum powder: 20 parts; talcum powder: 15 parts; polyacrylate: 1 part ; 5-chloro-2-methyl-4-isothiazolin-3-one: 1 part; anti-yellowing agent: 1 part; sodium hexametaphosphate: 0.2 part, nonionic polyurethane associative modifier: 0.2 Parts, alkali-swellable emulsion type leveling agent: 0.2 parts, mineral oil defoamer: 0.2 parts, water-soluble non-ionic low-foaming surface wetting agent: 0.2 parts; water: 10 parts.

[0030] Add the above components into a high-speed disperser and stir for 10 minutes, then continue to stir for 10 minutes after cooling, and obtain the molding paste for painting after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com