Composite film of polyolefin porous film and aramid fiber nanofiber, composite method and application

A nanofiber, porous membrane technology, applied in the field of membrane materials for chemical power sources or chemical energy storage elements, can solve the problems of complex preparation process, increased interface resistance, thick membrane thickness, etc., and achieve high ionic conductivity and increased interface resistance. Large, heat resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

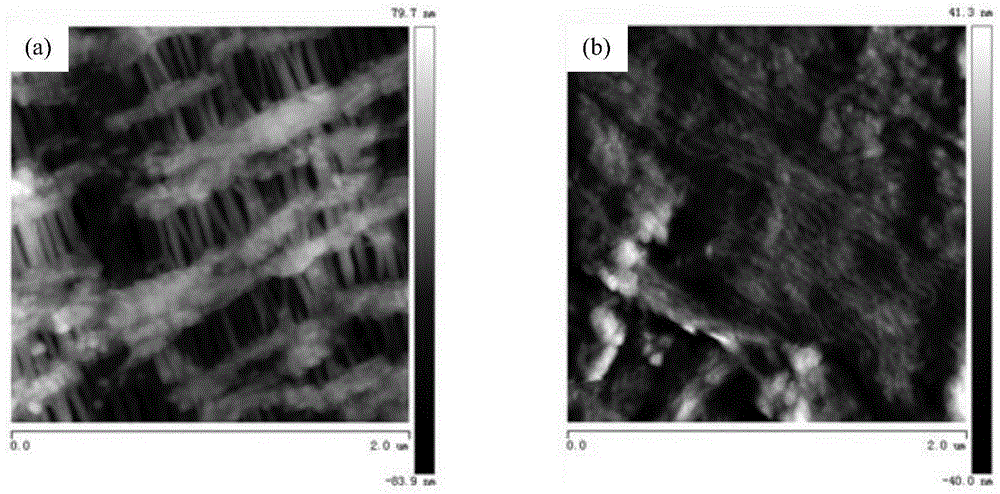

[0033] A composite membrane of polypropylene porous membrane and aramid fiber nanofiber is prepared by the following method:

[0034] (1) The preparation method of aramid nanofiber dispersion can refer to the literature reported by M. Yang et al. (ACS Nano, 2011, 5(9), pp 6945-6954). Be the preparation of 2% aramid nanofiber dispersion liquid as an example with the mass fraction, its preparation method is: aramid yarn (the Kevlar fiber of Du Pont Company) is cut into the chopped fiber of length 1cm, then by mass ratio, 2 Add the obtained chopped aramid yarn, 2 parts of KOH (or t-BuOK) and 96 parts of dimethyl sulfoxide into a sealed container, and stir at room temperature for 3 to 10 days to prepare aramid nanofibers Dispersions.

[0035] (2) Using the method reported by Myung-Hyun Ryou et al. (see: Adv. Mater., 2011, 23, 3066–3070) using dopamine to self-polymerize at room temperature in a Tris-HCl buffer solution with pH = 8.5 to form porous polypropylene Phenolic hydroxyl...

Embodiment 2

[0038] A composite membrane of polypropylene porous membrane and aramid fiber nanofiber is prepared by the following method:

[0039] (1) The preparation of the aramid nanofiber dispersion is the same as in Example 1.

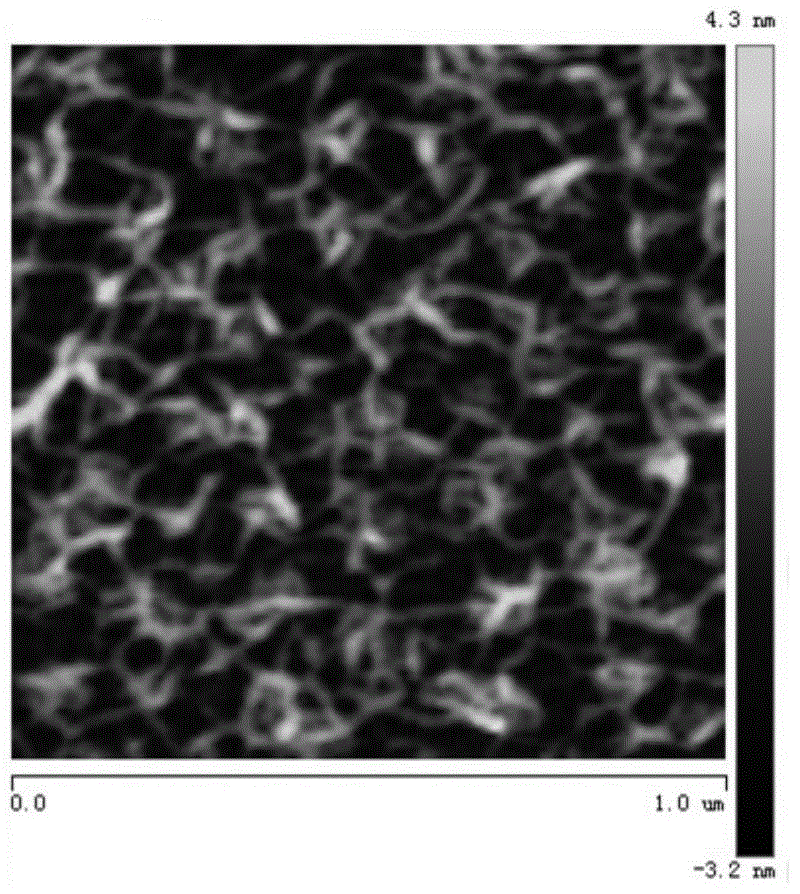

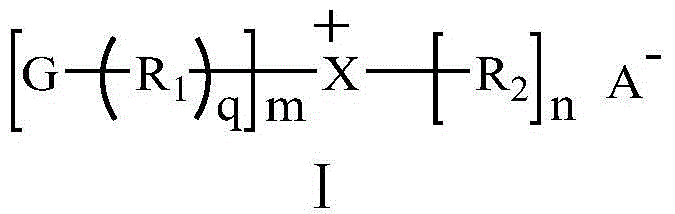

[0040] (2) The preparation of the polypropylene porous membrane with hydroxyl on the surface is the same as that in Example 1. The polypropylene porous membrane with hydroxyl on the surface and the compound of formula II (CAS: 3033-77-0, purchased from Sinopharm Group Chemical Reagent Co., Ltd.) React in water at 60°C for 5 hours to make the surface of the polypropylene porous membrane positively charged. Soak the positively charged polypropylene porous membrane in a concentration of 1×10 -2 % aramid nanofiber dispersion for 3 minutes, then take it out, wash it with water, and dry it at 80° C. for 10 minutes. This cycle is repeated 10 times to obtain a composite membrane with 10 layers of aramid nanofiber attached to the surface of the polypropylene porous mem...

Embodiment 3

[0042] A composite membrane of polypropylene porous membrane and aramid fiber nanofiber is prepared by the following method:

[0043] (1) The preparation of the aramid nanofiber dispersion is the same as in Example 1.

[0044] (2) The preparation of the polypropylene porous membrane with hydroxyl on the surface is the same as that in Example 1. The polypropylene porous membrane with hydroxyl on the surface and the compound of formula II (CAS: 3033-77-0, purchased from Sinopharm Group Chemical Reagent Co., Ltd.) React in water at 60°C for 5 hours to make the surface of the polypropylene porous membrane positively charged. Soak the positively charged polypropylene porous membrane in a concentration of 1×10 -2 % aramid nanofiber dispersion for 3 minutes, then take it out, wash it with water, and dry it at 80°C for 10 minutes. This cycle is repeated 15 times to obtain a composite membrane with 15 layers of aramid nanofibers attached to the surface of the polypropylene porous memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com