Metro traction inverter chopper power unit

A wave power and inverter technology, applied in the field of subway traction inverter chopper power unit, can solve the problems of unguaranteed reliability, cumbersome and time-consuming, and increased electrical gap, so as to save operating costs, improve maintenance efficiency, and replace and maintain convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

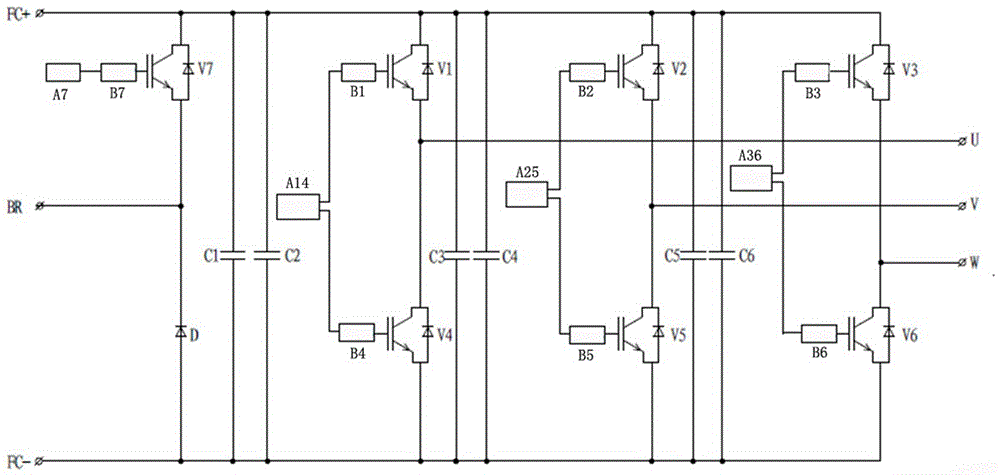

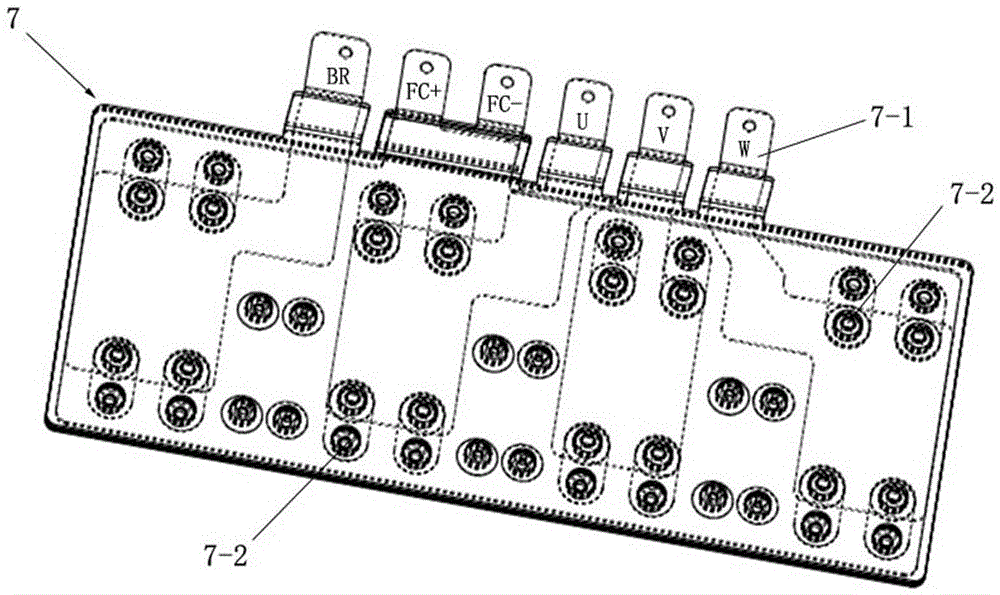

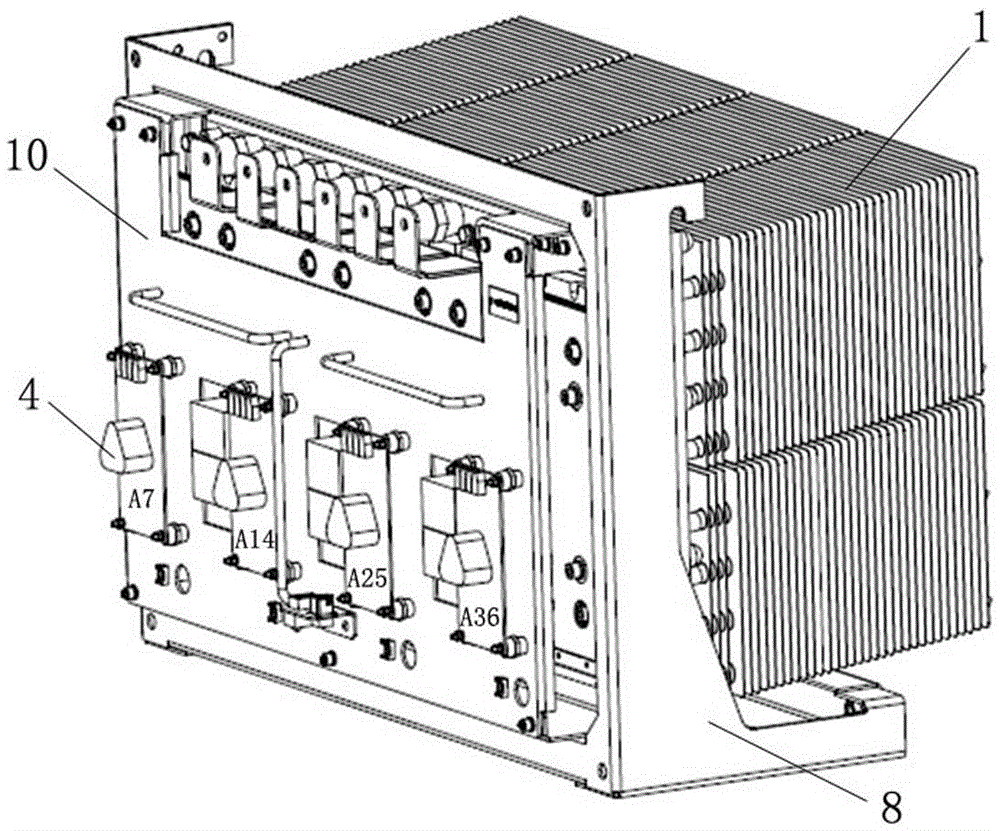

[0025] Such as Figure 1 to Figure 5 As shown, a subway traction inverter chopper power unit includes a radiator 1, an IGBT device 2, an IGBT configuration board 3, an IGBT driver board 4, a diode device 5, an absorbing capacitor 6 and a composite busbar 7; A support frame 8 is installed, and six insulators 9 are arranged on the support frame 8; the number of IGBT devices 2 is seven, the number of diode devices 5 is one, and the seven IGBT devices 2 and one diode device 5 are pasted in two rows Attached to the heat sink 1, one row is four IGBT devices 2, the other row is a diode device 5 and three IGBT devices 2; the number of IGBT configuration boards 3 is seven, and the seven IGBT configuration boards 3 are installed On the corresponding IGBT device 2; the composite busbar 7 is covered and attached to seven IGBT devices 2 and one diode device 5. The composite busbar 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com