A high-speed turbulent flow bioreactor and sewage treatment system

A bioreactor, high-speed technology, applied in the field of sewage treatment, can solve the problems of high operating cost and high energy consumption, and achieve the effects of reducing energy consumption, short residence time, and high oxygenation and aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

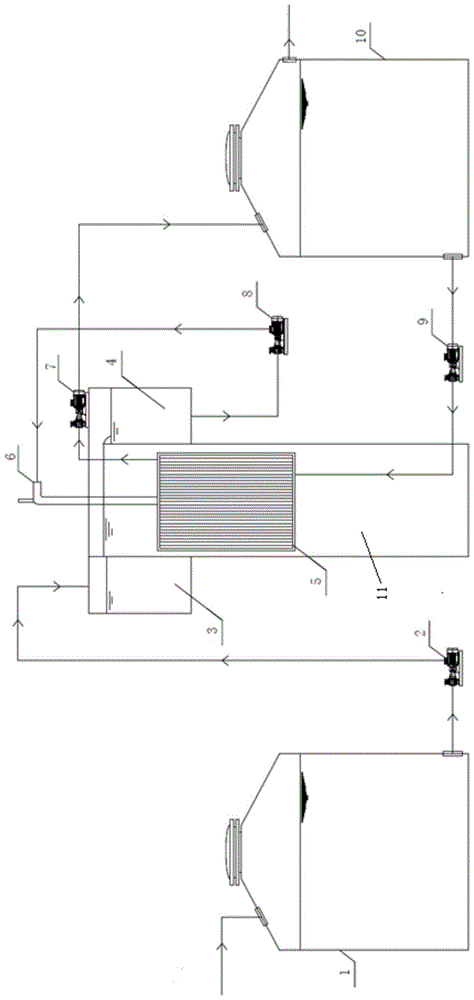

[0032] see figure 1, a high-speed turbulent flow bioreactor for treating sewage, including anoxic reaction pool 3, aerobic reaction pool 11, jet pool 4, high-speed turbulence device 6, built-in ultrafiltration membrane 5 and backwashing device, the The top of the anoxic reaction pool 3 is provided with an overflow weir 1, and the sewage in the anoxic reaction pool 3 can flow into the jet pool 4 through the overflow weir 1, and the sewage in the jet pool 4 can pass through the circulation pump 8 and the high-speed turbulence device 6 enter the aerobic reaction tank 11, the built-in ultrafiltration membrane 5 is arranged in the middle of the aerobic reaction tank 11, and the upper part of the aerobic reaction tank 11 is provided with an overflow flow weir II and overflow weir III, the sewage in the aerobic reaction tank 11 can flow into the anoxic reaction tank 3 and the jet pool 4 respectively through the overflow weir II and the overflow weir III, The sewage in the aerobic re...

Embodiment 2

[0041] The present invention also provides a sewage treatment system, which includes the high-speed turbulent flow bioreactor in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com