Preparation method of organic fertilizer raw material

A technology of organic fertilizer and raw materials, applied in the field of preparation of organic fertilizer raw materials, to achieve the effect of reducing pupa hatching, reducing capital and resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

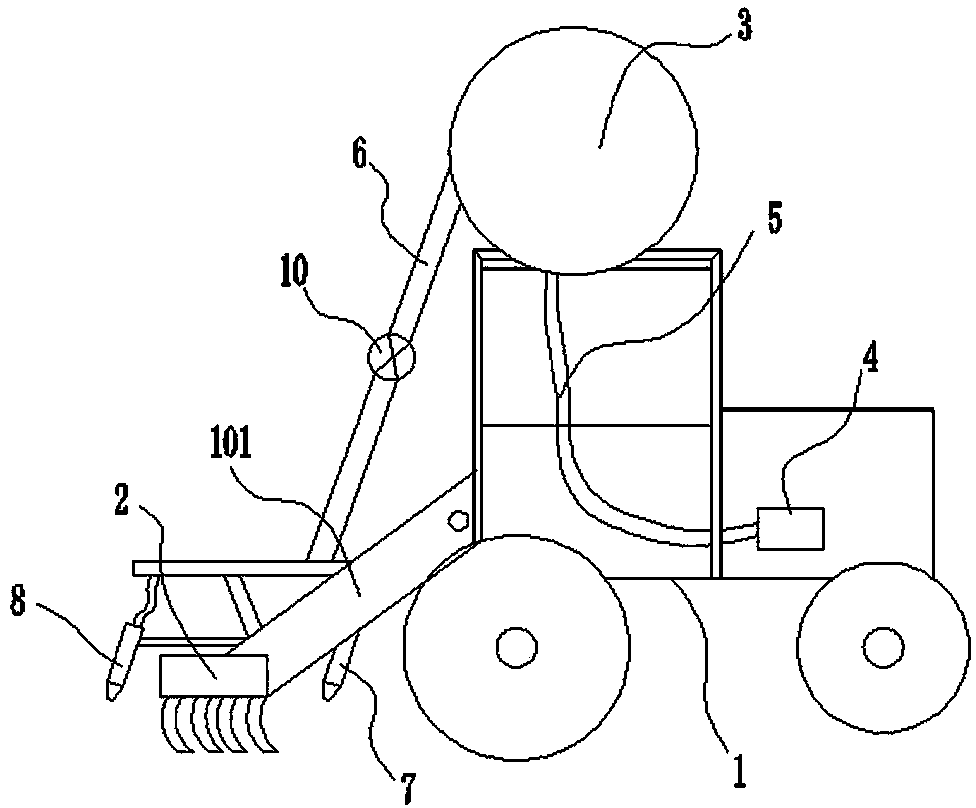

Image

Examples

preparation example Construction

[0027] A method for preparing organic fertilizer raw materials, including the following steps:

[0028] 1. Preparation of reagents:

[0029] According to the volume ratio of deodorant to water 1:150, after diluting the deodorant, the deodorant diluent is obtained for use; using sterile water, according to the volume ratio of EM bacteria stock solution and water is 1:200, Dilute the EM bacteria stock solution to obtain EM bacteria dilution A for use; use sterile water to dilute the EM bacteria stock solution according to the volume ratio of EM bacteria stock and water at 1:100 to obtain EM bacteria dilution B for use. ;

[0030] 2. Preparation of auxiliary materials:

[0031] Step 1: Transport the sewage sludge into the production shed, and the loader randomly spreads it on the flat ground of the production shed, and the thickness of the paving is 15-20cm;

[0032] Step 2. Use the rotary tillage sprayer to spray the deodorant diluent on the flat sludge, and perform 5-6 rotary tillage s...

Embodiment 1

[0046] A method for preparing organic fertilizer raw materials, including the following steps:

[0047] 1. Preparation of reagents:

[0048] According to the volume ratio of deodorant to water 1:150, after diluting the deodorant, the deodorant diluent is obtained for use; using sterile water, according to the volume ratio of EM bacteria stock solution and water is 1:200, Dilute the EM bacteria stock solution to obtain EM bacteria dilution A for use; use sterile water to dilute the EM bacteria stock solution according to the volume ratio of EM bacteria stock and water at 1:100 to obtain EM bacteria dilution B for use. ;

[0049] 2. Preparation of auxiliary materials:

[0050] Step 1: Transport the sewage sludge into the production shed, and the loader randomly spreads it on the flat ground of the production shed, and the thickness of the paving is 15 cm;

[0051] Step 2. Use the rotary tillage sprayer to spray the deodorant dilution liquid on the flat sludge, and perform 5 times rotary...

Embodiment 2

[0064] A method for preparing organic fertilizer raw materials, including the following steps:

[0065] 1. Preparation of reagents:

[0066] According to the volume ratio of deodorant to water 1:150, after diluting the deodorant, the deodorant diluent is obtained for use; using sterile water, according to the volume ratio of EM bacteria stock solution and water is 1:200, Dilute the EM bacteria stock solution to obtain EM bacteria dilution A for use; use sterile water to dilute the EM bacteria stock solution according to the volume ratio of EM bacteria stock and water at 1:100 to obtain EM bacteria dilution B for use. ;

[0067] 2. Preparation of auxiliary materials:

[0068] Step 1: Transport the sewage sludge into the production shed, and the loader randomly spreads it on the flat ground of the production shed, and the thickness of the paving is 18 cm;

[0069] Step 2. Use the rotary tillage sprayer to spray the deodorant diluent on the flat sludge and spray the deodorant diluent for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com