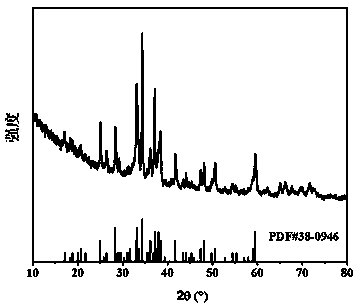

Ultraviolet-excited oxynitride red-light fluorescent powder and preparation method thereof

A red light phosphor, nitrogen oxide technology, applied in chemical instruments and methods, luminescent materials and other directions, can solve the problems of harsh synthesis conditions, low red light luminous efficiency, etc., achieve good chemical stability and thermal stability, The effect of high luminous brightness and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) According to the chemical formula Ca 2 AlSi 3 o 2 N 5 :0.001Sm 3+ Weigh CaCl according to stoichiometric ratio 2 , AlCl 3 ·6H 2 O, Nano-Si 3 N 4 , SmCl 3 ·6H 2 O, disperse the three chlorides in the above raw materials in a sufficient amount of isopropanol, stir and reflux at a constant temperature of 80°C until completely dissolved, and then add nano-Si 3 N 4 Add to the above solution, continue to reflux and stir at 80°C for 2 hours to form a uniformly dispersed white suspension;

[0019] 2) Weigh the amount of the substance as CaCl 2 15 times of CO(NH 2 ) 2 , disperse it in a sufficient amount of isopropanol, stir and reflux at a constant temperature of 80°C until completely dissolved; CO(NH 2 ) 2 Add the isopropanol solution to the above suspension, and continue to reflux and stir at 80°C for 2 hours to obtain nano-Si 3 N 4 Precipitate of the precursor with the core and the urea complex of chloride as the shell;

[0020] 3) The precipitate was s...

Embodiment 2

[0023] 1) According to the chemical formula Ca 2 AlSi 3 o 2 N 5 :0.005Sm 3+ Weigh CaCl according to stoichiometric ratio 2 , AlCl 3 ·6H 2 O, Nano-Si 3 N 4 , SmCl 3 ·6H 2 O, disperse the three chlorides in the above raw materials in a sufficient amount of isopropanol, stir and reflux at a constant temperature of 70°C until completely dissolved, and then add nano-Si 3 N 4 Add to the above solution, continue to reflux and stir at 70°C for 2 hours to form a uniformly dispersed white suspension;

[0024] 2) Weigh the amount of the substance as CaCl 2 15 times of CO(NH 2 ) 2 , dispersed in a sufficient amount of isopropanol, stirred and refluxed at a constant temperature of 70°C until completely dissolved; CO(NH 2 ) 2 Add the isopropanol solution to the above suspension, and continue to reflux and stir at 70°C for 2 hours to obtain nano-Si 3 N 4 Precipitate of the precursor with the core and the urea complex of chloride as the shell;

[0025] 3) The precipitate wa...

Embodiment 3

[0027] 1) According to the chemical formula Ca 2 AlSi 3 o 2 N 5 :0.01Sm 3+ Weigh CaCl according to stoichiometric ratio 2 , AlCl 3 ·6H 2 O, Nano-Si 3 N 4 , SmCl 3 ·6H 2 O, disperse the three chlorides in the above raw materials in a sufficient amount of isopropanol, stir and reflux at a constant temperature of 90°C until completely dissolved, and then add nano-Si 3 N 4 Add to the above solution, continue to reflux and stir at 90°C for 1 hour to form a uniformly dispersed white suspension;

[0028] 2) Weigh the amount of the substance as CaCl 2 15 times of CO(NH 2 ) 2, disperse it in a sufficient amount of isopropanol, stir and reflux at a constant temperature of 90°C until completely dissolved; CO(NH 2 ) 2 The isopropanol solution was quickly added to the above suspension, and continued to reflux at 90°C for 1 hour to obtain nano-Si 3 N 4 Precipitate of the precursor with the core and the urea complex of chloride as the shell;

[0029] 3) The precipitate was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com