Ring spinning fuzzy yarn winding and attaching device based on double-roller rubbing and application

A technology of ring spinning and spinning, applied in the field of cotton textile spinning, can solve the problems of reducing yarn hairiness index, reducing hairiness, increasing cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

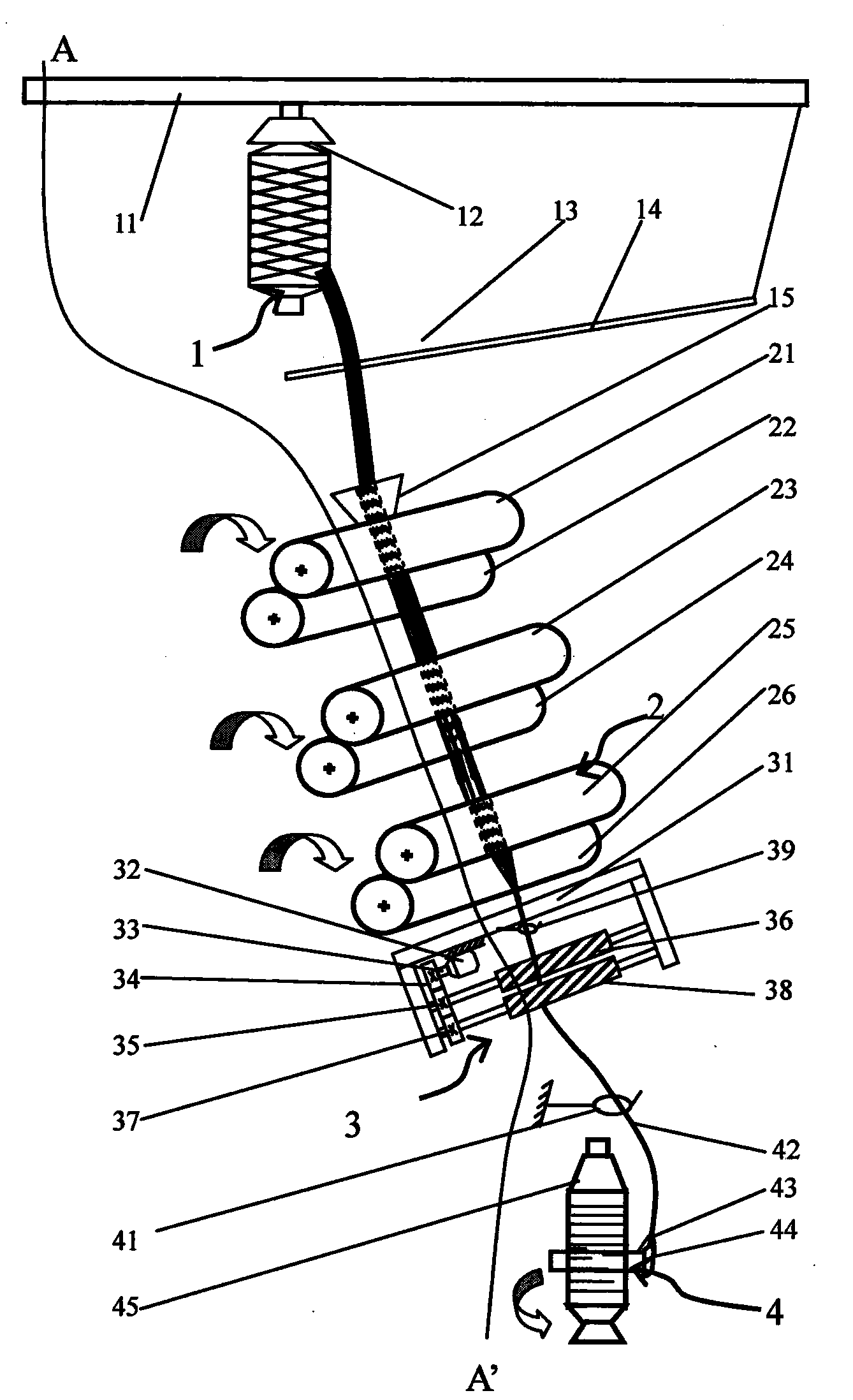

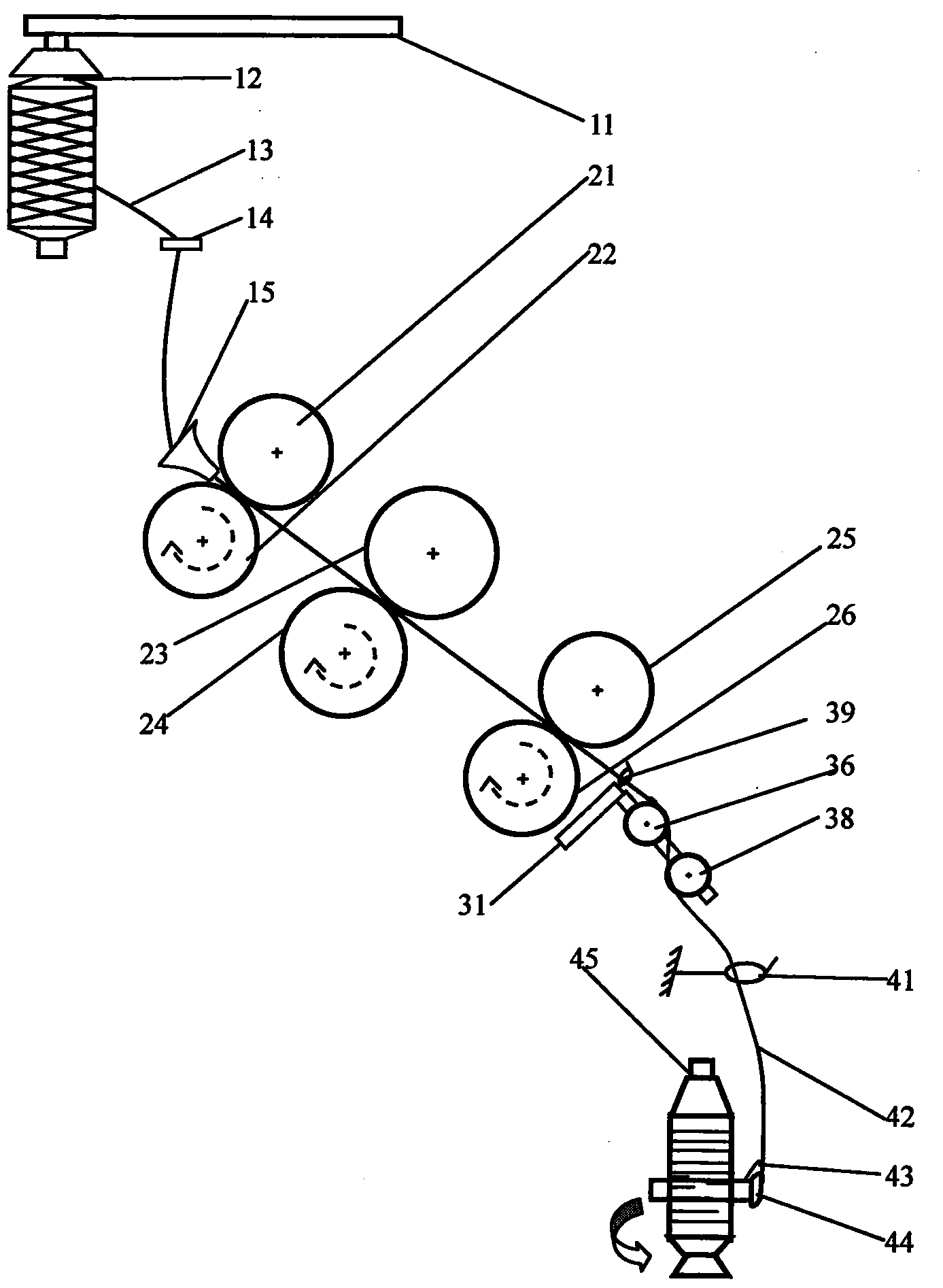

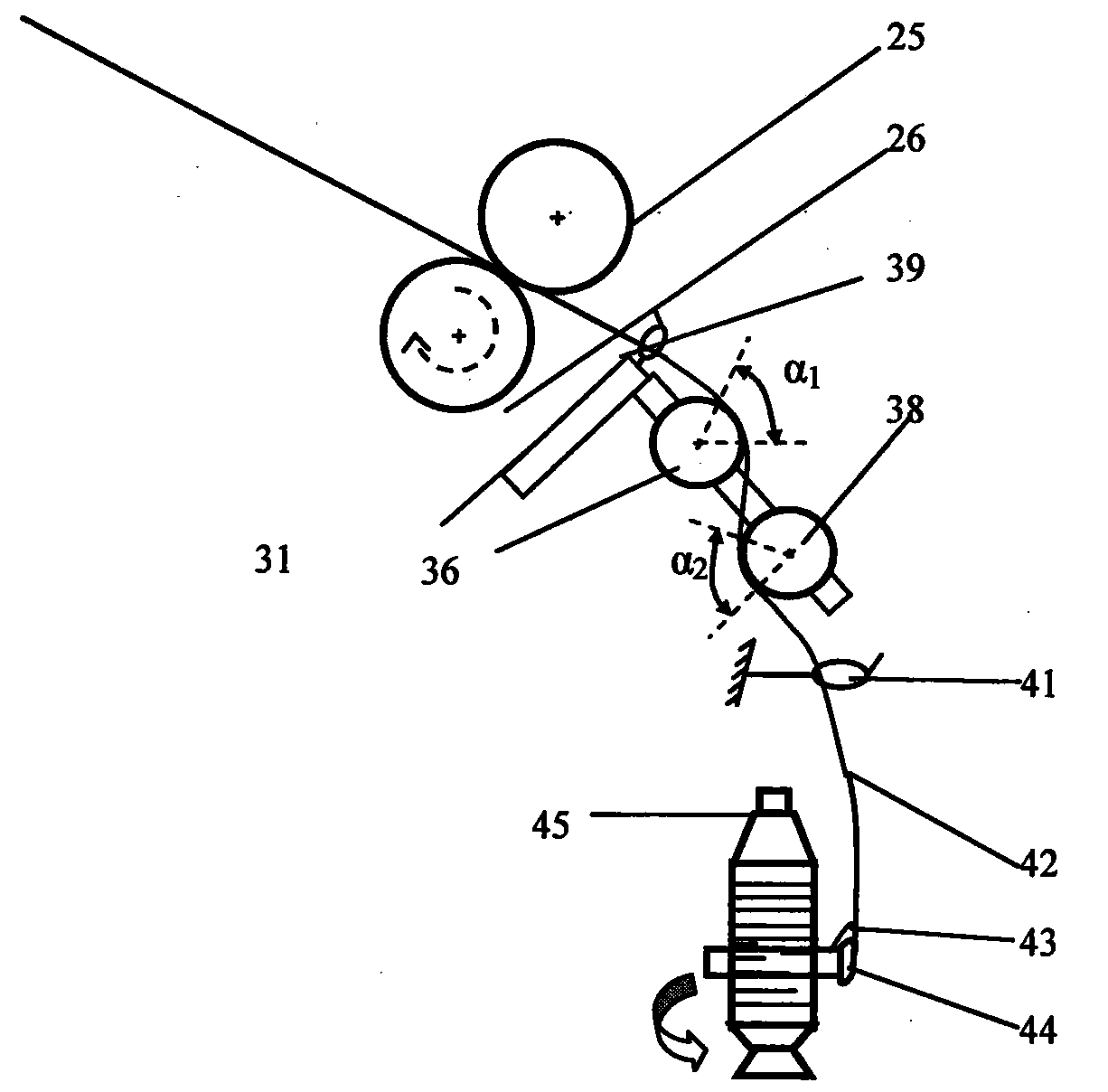

[0040] Such as figure 1 As shown, it is a front view of the ring spun spun yarn hairiness wrapping device based on double-roll rubbing, and the ring spinning hairiness wrapping device based on double-roll rubbing consists of a roving supply mechanism 1, a draft mechanism 2, The hairiness wrapping mechanism 3 and the twisting winding mechanism 4 constitute. Described roving supply mechanism 1 is made of upper beam 11, roving tube 12, roving 13, guide rod 14 and cluster horn 15; Described roving tube 12 is suspended on the upper beam 11, as figure 2 As shown, the roving 13 is drawn to the nip of the rear top roller 21 and the rear bottom roller 22 of the drafting mechanism 2 via the yarn guide bar 14 and the cluster horn 15; Roller 22, upper middle roller 23, lower middle roller 24, upper front roller 25 and lower front roller 26, upper rear roller 21, lower rear roller 22, upper middle roller 23, lower middle roller 24 form the first draft zone; the middle top roller 23, the...

Embodiment 2

[0044] Example 2 Preparation of polyester-cotton 85 / 15 blended yarn with less hairiness, low energy consumption and uniform dryness

[0045] Use the ring spinning spun yarn hairiness wrapping device based on double-roll rubbing described in Example 1 to attach yarn hairiness, and then implement polyester-cotton 85 / 15 blended yarn with less hairiness, low energy consumption, and uniform dryness The preparation method is: draw the polyester-cotton 85 / 15 blended roving from the roving bobbin 12, and then draw it to the nip of the rear upper roller 21 and the rear lower roller 22 of the drafting mechanism 2 through the yarn guide rod 14 and the cluster horn 15 in turn. place; the roving 13 is sequentially driven by the rotation of the rear top roller 21 and the rear bottom roller 22, the rotation and traction of the middle top roller 23 and the middle bottom roller 24 to the output of the front top roller 25 and the front bottom roller 26; Mechanism 3 is combed, and the yarn outpu...

Embodiment 3

[0046] Example 3 Preparation of Polyester / Viscose 85 / 15 Blended Yarn with Less Hairiness, Low Energy Consumption, and Evenness

[0047]Use the ring spinning spun yarn hairiness sticking device based on double-roll rubbing described in Example 1 to attach the yarn hairiness, and then implement the polyester-viscose 85 / 15 blended yarn with less hairiness, low energy consumption, and uniform dryness The preparation method is as follows: the polyester-viscose 85 / 15 blended roving is drawn from the roving bobbin 12, and then drawn to the nip of the rear upper roller 21 and the rear lower roller 22 of the drafting mechanism 2 through the yarn guide rod 14 and the cluster horn 15 in turn. place; the roving 13 is sequentially driven by the rotation of the rear top roller 21 and the rear bottom roller 22, the rotation and traction of the middle top roller 23 and the middle bottom roller 24 to the output of the front top roller 25 and the front bottom roller 26; Mechanism 3 is combed, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com