Method for extracting collagen using ultrasonic waves, and apparatus therefor

A collagen and ultrasonic technology, which is applied in the preparation method of peptides, the method of stress-stimulated microbial growth, chemical instruments and methods, etc., can solve the problems of waste water treatment cost and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1. Pretreatment of sample

[0059] As a sample, the frozen skin of sea bass supplied from O Sung Fish Farm was used. After removing the perch muscle and scales remaining on a part of the inside, the fish skin is washed with ice water to remove impurities, and then finely cut to a size of 1.0cm×1.0cm. In order to completely remove the salt-soluble protein adhering to the fish skin, after adding 0.5M NaCl solution 20 times the weight of the fish skin, stir evenly and perform centrifugation at 6,000rpm for 10 minutes to remove the supernatant liquid. The above operations were repeated three times, and all operations were performed below 4°C. After the precipitate obtained by centrifugation was washed again with purified water stored at 4°C or less, cold ethanol about 20 times the weight of the precipitate was added to the precipitate, and it was degreased while stirring at 4°C for 24 hours to make it a purified sample. Refined samples are stored below -20°...

Embodiment 2

[0060] Example 2. Extraction of Collagen

[0061] 2-1. Extraction of collagen by ultrasonic treatment

[0062] After adding approximately 200 times the weight of 0.01 to 0.5 M acetic acid to the fish skin prepared in Example 1, ultrasonic treatment was performed at 4° C. under the conditions in Table 1 below. Pulse on / off is performed at 20sec / 20sec. After centrifuging the viscous solution obtained after ultrasonic treatment at 6,000 rpm for 10 minutes, the supernatant was separated, and NaCl was added to the supernatant so as to be 5 wt % to obtain a white precipitate. The white precipitate was centrifuged and dialyzed into purified water, and then freeze-dried to extract collagen.

[0063] Table 1

[0064]

[0065] 2-2. Extraction of acid-soluble collagen

[0066] Under the conditions of the following Table 2, acetic acid of 0 to 0.5 M was added 200 times with respect to the sample weight, and it extracted while stirring at 4 degreeC for 24 hours. After the vis...

Embodiment 3

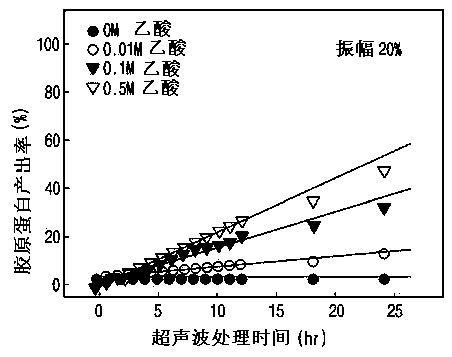

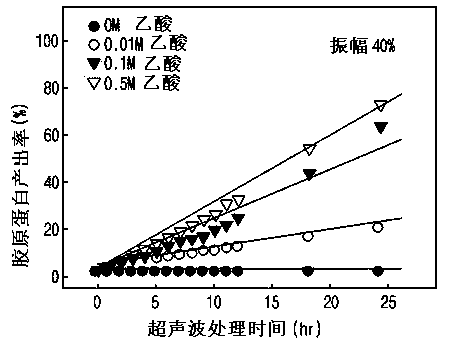

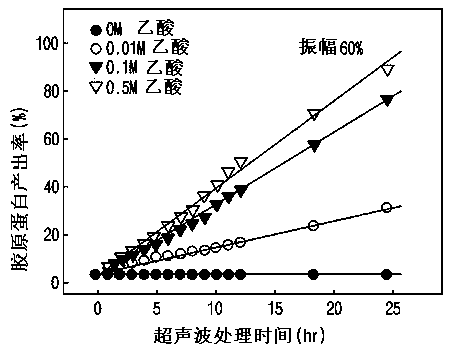

[0071] Example 3. Determination of Collagen Output Rate

[0072] Using the Biuret (biuret) method (Gornall, A, G. et al., 1949), the protein content was measured on the supernatant obtained in the above-mentioned Production Examples and Comparative Examples at 15,000 x g. The sample was obtained by centrifugation for 20 minutes. Collagen production rate was calculated according to the following formula as the ratio of protein content after ultrasonic treatment of total protein content.

[0073] Collagen production rate (%) = (protein concentration in supernatant / total protein concentration) × 100

[0074] The collagen production rate according to the treatment time is shown in Figure 1 to Figure 5 . Figures 1 to 4 Shows the production rate of collagen according to the concentration of acetic acid in Production Examples 1 to 4, Figure 5 The production rate of collagen according to the acid concentration of Comparative Examples 1 to 5 is shown. according to Figures 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com