Preparation method of flame-retardant borate-intercalated hydrotalcite-polypropylene compound

A borate intercalation and hydrotalcite technology, which is applied in the field of flame retardant polypropylene composites, can solve the problems of poor compatibility with polymer materials, poor compatibility, easy precipitation, etc., and achieves good compatibility, uniform dispersion, and improved dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

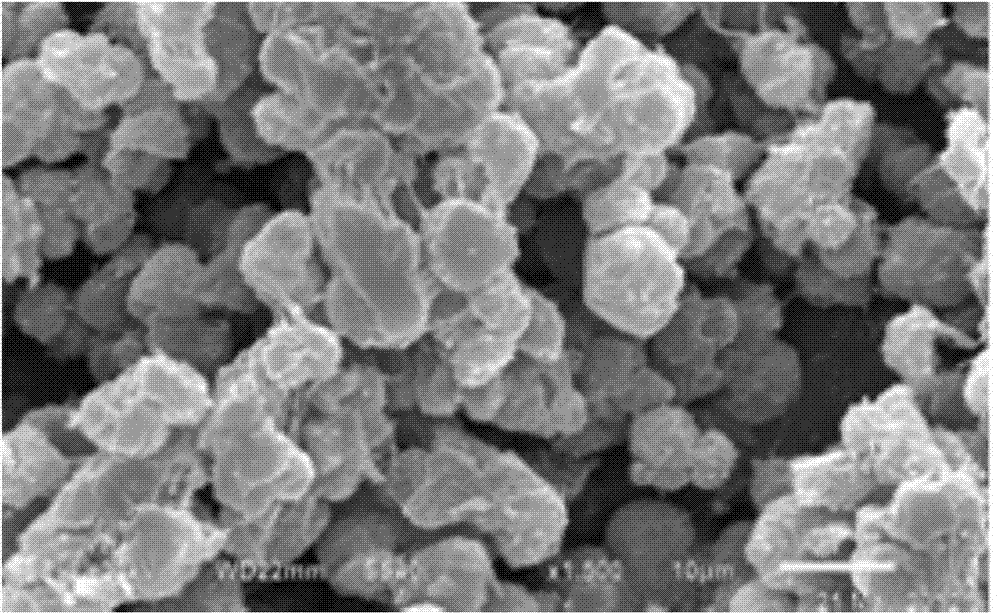

[0045] Preparation of borate intercalated hydrotalcite: weigh 11.14g (0.0375mol) of Zn(NO 3 ) 2 ·6H 2 O and 7.025g (0.0187mol) of Al(NO 3 ) 3 9H 2O was dissolved in 50ml of water to prepare zinc-aluminum metal salt solution A; weigh 5.225g (0.085mol) of H 3 BO 3 , prepare boric acid solution B; under the condition of constant stirring, drop solution B into solution A, and control the pH value at about 8.3 by adding 1mol / L NaOH solution dropwise, the whole reaction process is carried out under nitrogen protection, and the reaction After the end, wash and filter to neutrality to obtain borate intercalated hydrotalcite.

[0046] (1) Disperse the above-prepared borate intercalated hydrotalcite in 100ml of acetone, stir at room temperature for 1h, and then dry at 65°C for 12h.

[0047] (2) 0.3 g of hydrotalcite treated in step (1) and 4.7 g of polypropylene were added into 100 ml of xylene, and the mixture was stirred and refluxed at 140° C. for 2 h until the polypropylene w...

Embodiment 2

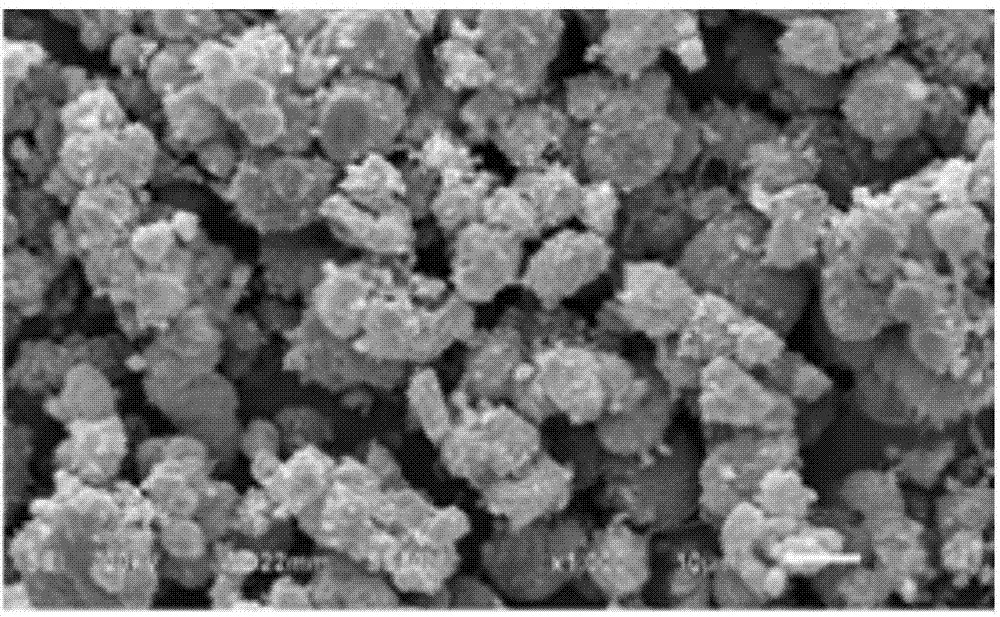

[0050] Preparation of borate intercalated hydrotalcite: weigh 11.14g (0.0375mol) of Zn(NO 3 ) 2 ·6H 2 O and 7.025g (0.0187mol) of Al(NO 3 ) 3 9H 2 O was dissolved in 50ml of water to prepare zinc-aluminum metal salt solution A; weigh 5.225g (0.085mol) of H 3 BO 3 , prepare boric acid solution B; under the condition of constant stirring, solution B is added dropwise in solution A, and by dropping 1M NaOH, the pH value is controlled at about 8.3, and the whole reaction process is under N 2 Carried out under protection, after the reaction, washing and suction filtering to neutrality to obtain borate intercalated hydrotalcite.

[0051] (1) Disperse the prepared hydrotalcite in 100ml of acetone, stir at room temperature for 1h, and then dry at 65°C for 12h.

[0052] (2) 0.75 g of hydrotalcite treated in step (1) and 4.25 g of polypropylene were added into 100 ml of xylene, and the mixture was stirred and refluxed at 140° C. for 2 h until the polypropylene was completely diss...

Embodiment 3

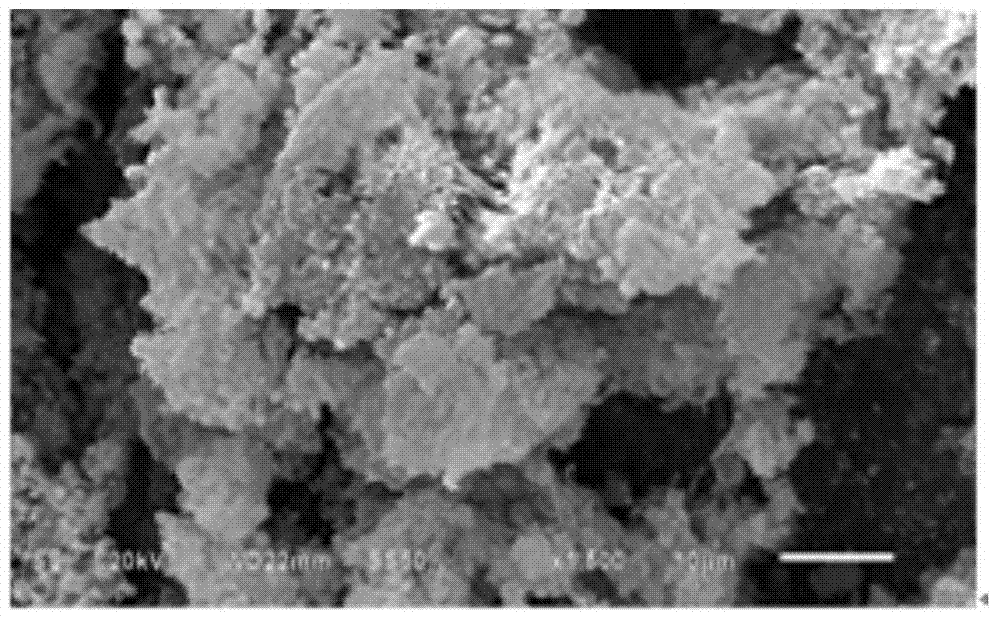

[0055] Preparation of borate intercalated hydrotalcite: weigh 11.14g (0.0375mol) of Zn(NO 3 ) 2 ·6H 2 O and 7.025g (0.0187mol) of Al(NO 3 ) 3 9H 2 O was dissolved in 50ml of water to prepare zinc-aluminum metal salt solution A; weigh 5.225g (0.085mol) of H 3 BO 3 , prepare boric acid solution B; under the condition of constant stirring, solution B is added dropwise in solution A, and by dropping 1M NaOH, the pH value is controlled at about 8.3, and the whole reaction process is under N 2 Carried out under protection, after the reaction, washing and suction filtering to neutrality to obtain borate intercalated hydrotalcite.

[0056] (1) Disperse the hydrotalcite prepared above in 100 ml of acetone, stir at room temperature for 1 h, and then dry at 65° C. for 12 h.

[0057] (2) 1.5 g of hydrotalcite treated in step (1) and 3.5 g of polypropylene were added into 100 ml of xylene, and the mixture was stirred at 140° C. for 2 hours until the polypropylene was completely diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com