Homotropic conductive adhesive film and preparation method thereof

A conductive adhesive film and isotropic technology, applied in the field of conductive adhesive, can solve the problems of low bonding strength and poor heat resistance, and achieve the effects of low initial viscosity, excellent heat resistance and stable mechanical energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

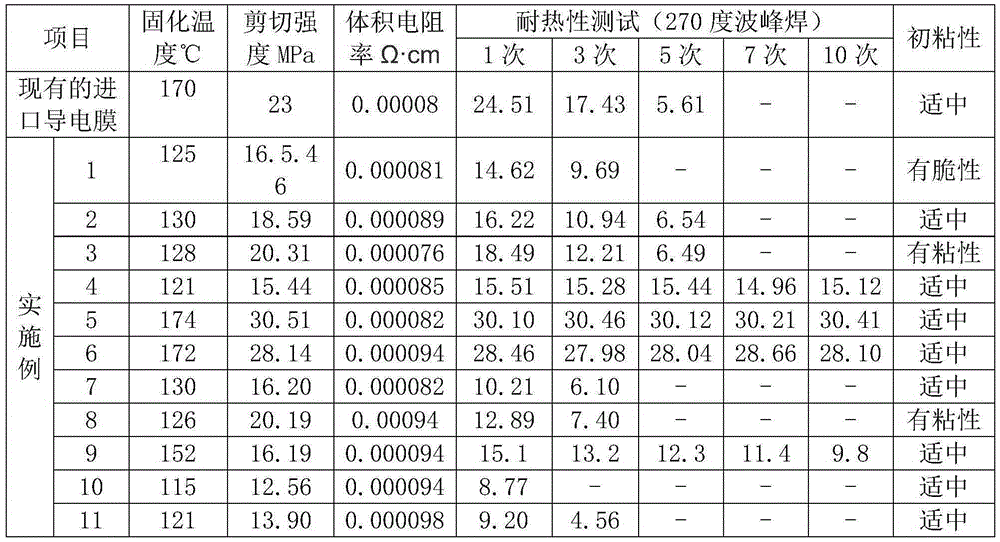

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned homotropic conductive adhesive film has the following steps:

[0024] (1) Preparation of glue

[0025] Mix 3-7 parts of liquid epoxy resin, 8-20 parts of solid epoxy resin with 50% solid content, 0-4 parts of modified epoxy resin and 0.5 parts of γ-(2,3-glycidoxy) propyl Mix trimethoxysilane evenly, then add 15 parts of butyl acetate, then add 83 parts of flaky silver powder (diameter 6-9um), disperse the above mixture evenly at high speed, finally add 1-4 parts of curing agent, stir evenly, and make a glue liquid.

[0026] (2) Coating film formation

[0027] Coat the glue solution in the above examples on the PET release film by a coating machine. After coating, cut the PET release film into slices and bake in a 60-80°C oven for 10-30 minutes. Minutes, that is, to complete the isotropic conductive adhesive film of the present embodiment by baking.

Embodiment 1

[0030] The homotropic conductive adhesive film of embodiment 1 is made from the raw material of following parts by weight: 83 parts of flaky silver powder (diameter 6-9um), the solid epoxy resin of 20 parts of 50% solid content, 15 parts of butyl acetate, 0.5 Parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 3 parts of liquid epoxy resin, 4 parts of rubber-modified epoxy resin, 1 part of amine curing agent, and 0.4 parts of imidazole curing agent.

[0031] The preparation method of the above-mentioned homotropic conductive adhesive film has the following steps:

[0032] (1) Preparation of glue

[0033] First add 4 parts of rubber-modified epoxy resin to 3 parts of liquid epoxy resin, then add 0.5 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane, heat and stir to mix, dissolve and cool , then add 20 parts of solid epoxy resin with 50% solid content, then add 15 parts of butyl acetate, stir and mix evenly, then add 83 parts of flaky silver powder (diameter 6-9um), stir and m...

Embodiment 2

[0037] The homotropic conductive adhesive film of embodiment 2 is made from the raw material of following parts by weight: 83 parts of flaky silver powder (diameter 6-9um), the solid epoxy resin of 16 parts of 50% solid content, 15 parts of butyl acetate, 0.5 Parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 5 parts of liquid epoxy resin, 4 parts of rubber-modified epoxy resin, 1 part of amine curing agent, and 0.4 parts of imidazole curing agent.

[0038] The preparation method of the above-mentioned homotropic conductive adhesive film has the following steps:

[0039] (1) Preparation of glue

[0040] First add 4 parts of rubber modified epoxy resin to 5 parts of liquid epoxy resin, then add 0.5 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, heat and stir to mix, dissolve and cool , then add 16 parts of solid epoxy resin with 50% solid content, then add 15 parts of butyl acetate, stir and mix evenly, then add 83 parts of flaky silver powder (diameter 6-9um), stir an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com