Method for preparing biogas and soil conditioner by utilizing stevia rebaudiana processing waste

A soil conditioner, biogas technology, applied in waste fuels, chemical instruments and methods, soil conditioning materials, etc., can solve the problems of long-term stable operation, easy acidification, easy blockage, etc., to ensure long-term stable supply and solve easy problems. The effect of crusting and avoiding crusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

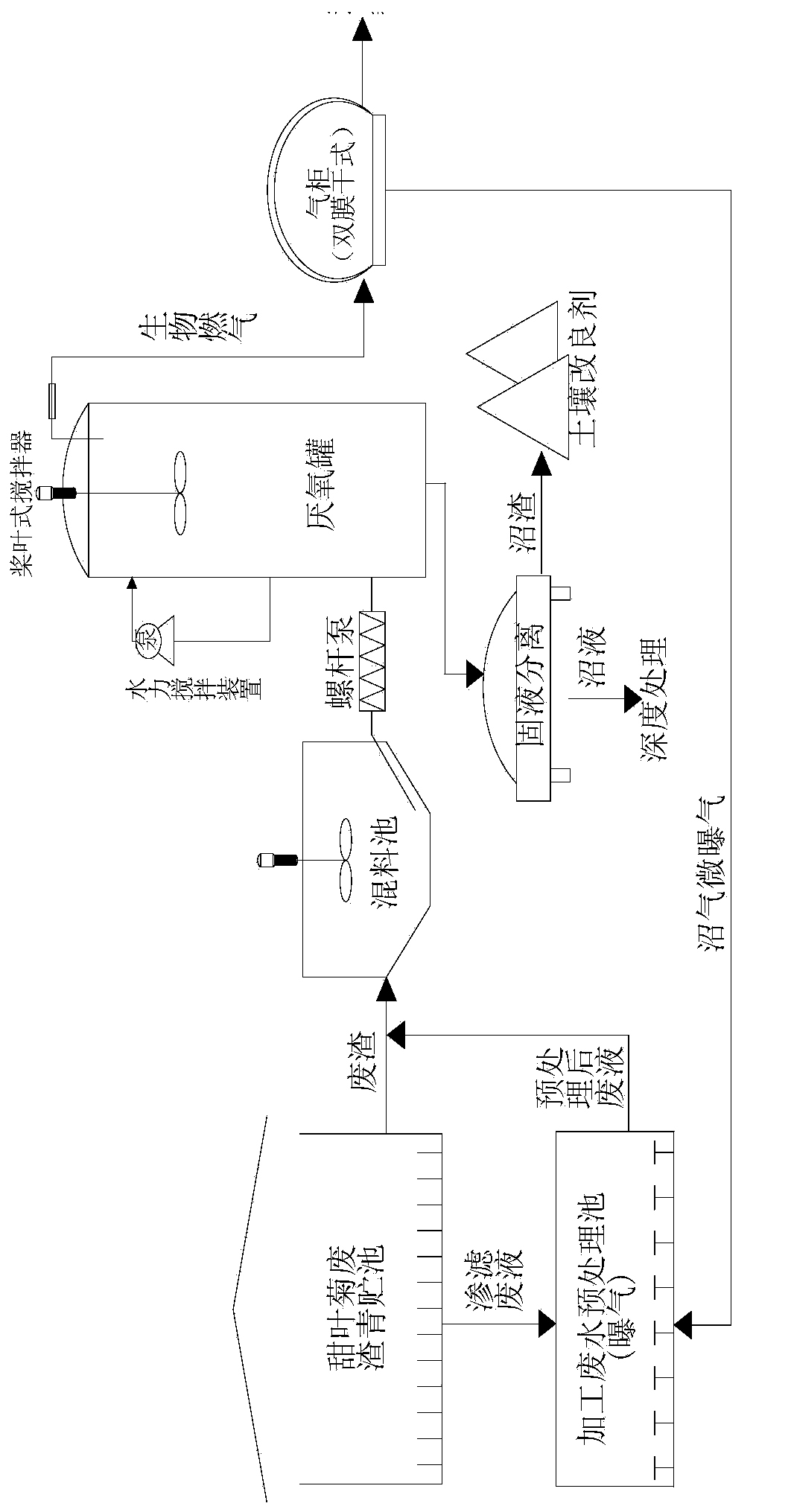

[0021] The technological process of this method Stevia rebaudiana processing waste treatment is as follows figure 1 Shown:

[0022] (1) Put the waste residue processed by stevia rebaudiana into a semi-closed waste residue silage tank for silage, and the bottom of the waste residue silage tank is provided with a leachate collection system, which can separate and flow out the waste liquid in the waste residue;

[0023] (2) There is a waste water pretreatment tank connected to the percolation collection system next to the waste silage tank, and the waste liquid separated from the waste silage process and the waste liquid produced in each processing step of stevia can be placed in the waste water pretreatment tank; The bottom of the wastewater pretreatment tank is equipped with an aeration device connected to the biogas tank. The wastewater is subjected to micro-aeration treatment and surface scum is removed through the aeration device. The treated wastewater and silage waste resi...

Embodiment 2

[0030] Stevia waste residue is stored in a semi-closed container for silage treatment, and the leachate is collected to the wastewater pretreatment tank; the stevia processing wastewater is placed in the wastewater pretreatment tank, and the wastewater in the wastewater pretreatment tank is treated with biogas in the gas cabinet. For aeration, the aeration rate is 1m 3 / (m 3 water d); then waste residue and pretreated waste water are put into the mixing tank for mixing, and the solid concentration is controlled to be 15%; the mixed raw materials are pumped into the fermenter for fermentation, and the fermentation temperature is controlled at 30°C, and the fermentation time For 25 days, the hydraulic agitation is started every 12 hours, 15 minutes each time; the produced gas enters the gas storage tank for cogeneration of heat and power; after the fermentation, the fermentation residue is separated from solid and liquid, dried, and the moisture content is controlled at 40% to ...

Embodiment 3

[0032] Stevia waste residue is stored in a semi-closed container for silage treatment, and the leachate is collected to the wastewater pretreatment tank; the stevia processing wastewater is placed in the wastewater pretreatment tank, and the wastewater in the wastewater pretreatment tank is treated with biogas in the gas cabinet. Aeration is carried out, the aeration rate is 3m 3 / (m 3 water d); then waste residue and waste water are put into the mixing tank for mixing, and the solid concentration is controlled to be 20%; the mixed raw materials are pumped into the fermentation tank for fermentation, the fermentation temperature is controlled at 55°C, and the fermentation time is 35 days. Stirring is started every 8 hours, each time for 30 minutes; the generated biogas enters the gas storage cabinet for the preparation of bio-natural gas; after the fermentation, the fermentation residue is separated from solid and liquid and dried, and the moisture content is controlled at 50%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com