High-toughness ultrafine-grain composite titanium alloy and application and preparation method thereof

A composite structure and titanium alloy technology, which is applied in the field of high-strength and toughness ultra-fine grain composite structure titanium alloy and its preparation, can solve the problem that there is no research report on high-strength and tough ultra-fine grain composite structure titanium alloy, narrow composition range and limited cooling rate. and other problems, to achieve the effect of saving raw materials, simple processing and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

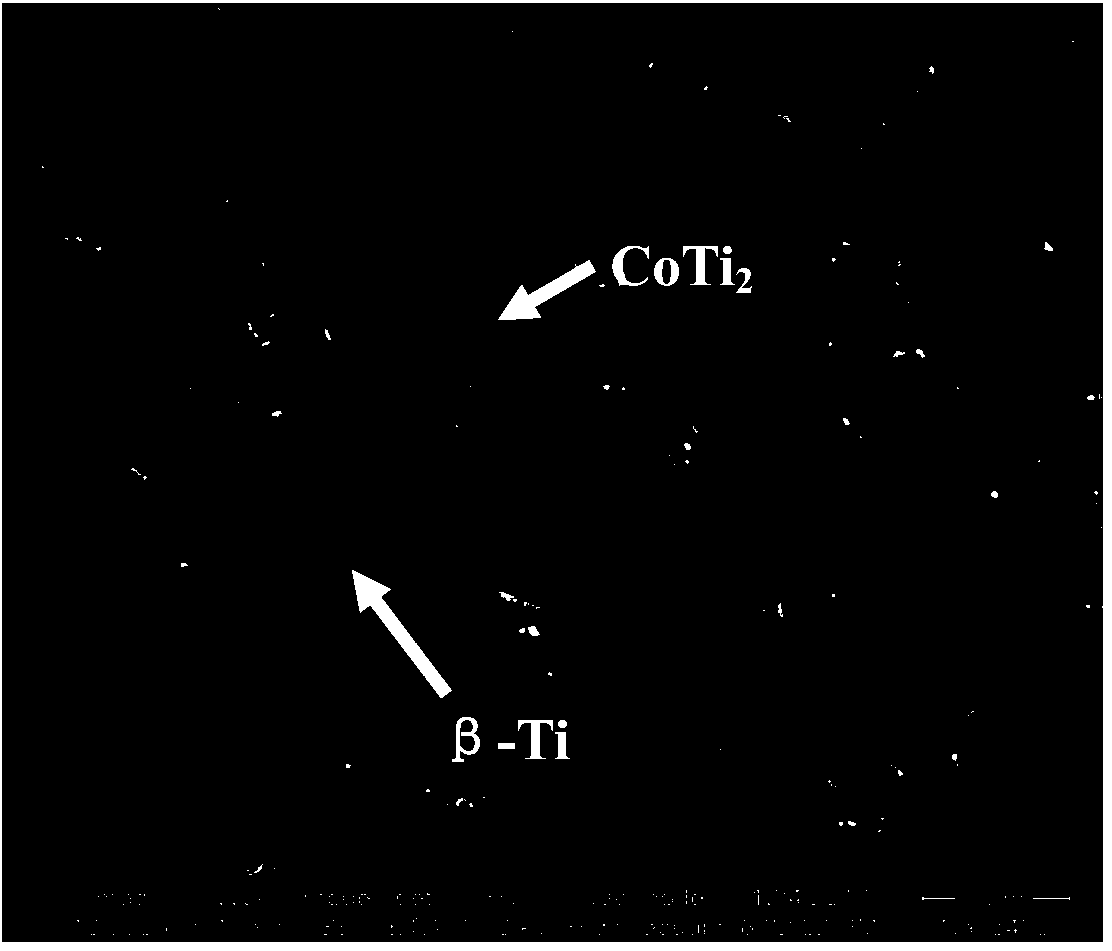

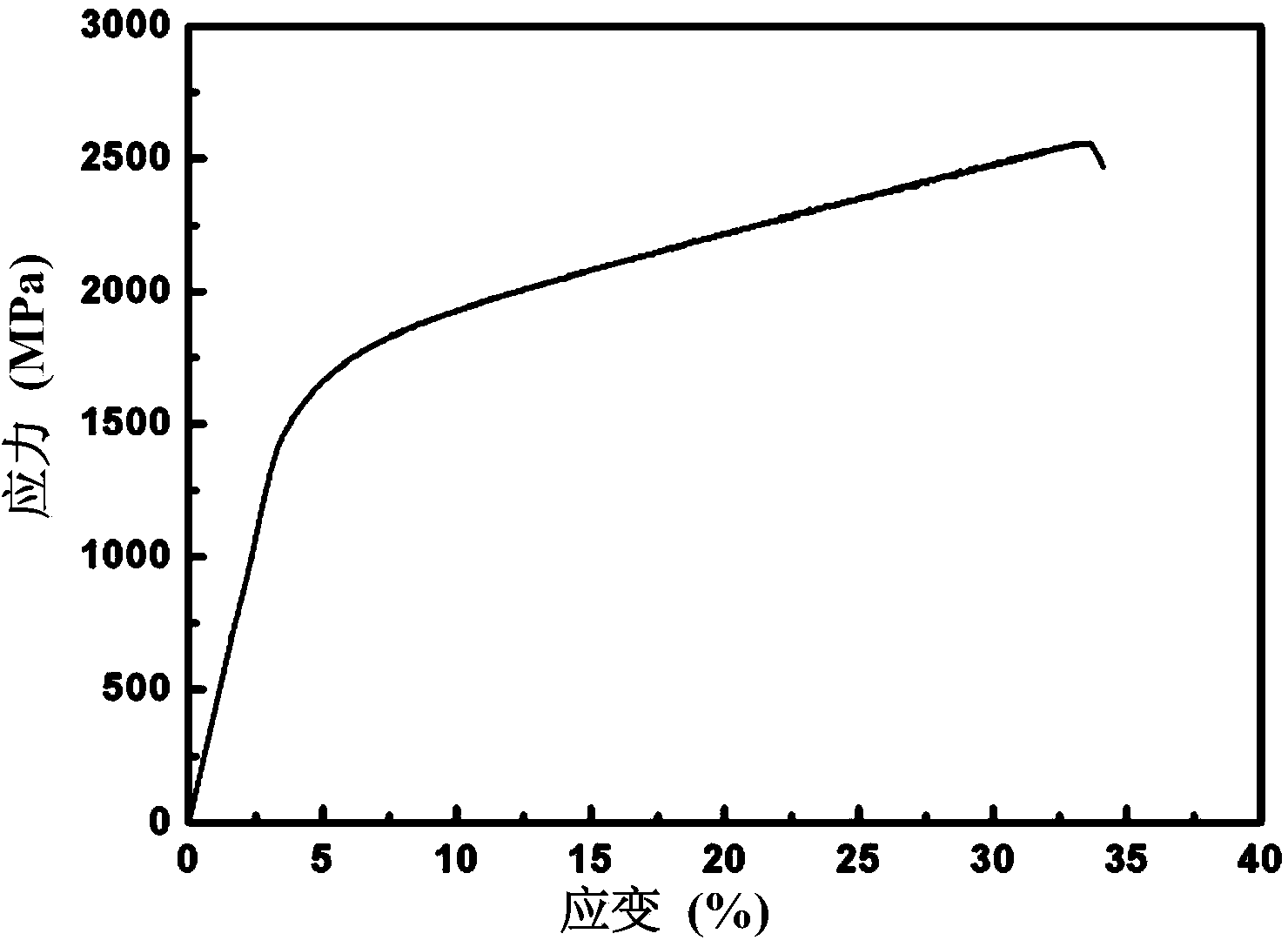

[0040] A high-strength and toughness ultra-fine-grain composite structure titanium alloy of this embodiment is prepared from the following components in mass percentage: Ti 58.70%, Nb 22.44%, Fe 8.33%, Co 7.45%, Al 3.15%.

[0041] The preparation method of the above-mentioned high-strength and tough ultrafine-grain composite structure titanium alloy, the specific operation steps are as follows:

[0042] (1) mixed powder

[0043] Mix the elemental powders with mass percentages of Ti 58.70%, Nb22.44%, Fe 8.33%, Co 7.45%, and Al 3.15% in a powder mixer, wherein the average particle size of each elemental powder is 75 μm;

[0044] (2) Preparation of amorphous alloy powder by high energy ball milling

[0045] Put the evenly mixed powder into a planetary ball mill (QM-2SP20) for high-energy ball milling. The ball milling media such as the tank body and ball materials are all stainless steel, and the diameters of the balls are 15mm, 10mm, and 6mm respectively. The weight of the three ...

Embodiment 2

[0056] A high-strength and toughness ultra-fine-grain composite structure titanium alloy of this embodiment is prepared from the following components in mass percentage: Ti 55%, Nb 15%, Fe 16%, Co 12%, Al 2%.

[0057] The preparation method of the above-mentioned high-strength and tough ultrafine-grain composite structure titanium alloy, the specific operation steps are as follows:

[0058] (1) mixed powder

[0059] Mix the elemental powders with mass percentages of Ti 55%, Nb15%, Fe 16%, Co 12%, and Al 2% in a powder mixer, wherein the average particle size of each elemental powder is 75 μm;

[0060] (2) Preparation of amorphous alloy powder by high energy ball milling

[0061] Put the evenly mixed powder into a planetary ball mill (QM-2SP20) for high-energy ball milling. The ball milling media such as the tank body and ball materials are all stainless steel, and the diameters of the balls are 15mm, 10mm, and 6mm respectively. The weight of the three balls The ratio is 1:3:...

Embodiment 3

[0072] A high-strength and toughness ultrafine-grain composite structure titanium alloy in this embodiment is prepared from the following components in mass percentage: Ti 62%, Nb 24%, Fe 6%, Co 2%, Al 6%.

[0073] The preparation method of the above-mentioned high-strength and tough ultrafine-grain composite structure titanium alloy, the specific operation steps are as follows:

[0074] (1) mixed powder

[0075] Mix the elemental powders with mass percentages of Ti 62%, Nb24%, Fe 6%, Co 2%, and Al 6% in a powder mixer, wherein the average particle size of each elemental powder is 75 μm;

[0076] (2) Preparation of amorphous alloy powder by high energy ball milling

[0077] Put the evenly mixed powder into a planetary ball mill (QM-2SP20) for high-energy ball milling. The ball milling media such as the tank body and ball materials are all stainless steel, and the diameters of the balls are 15mm, 10mm, and 6mm respectively. The weight of the three balls The ratio is 1:3:1. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com