Organic-silicon water-repellent agent, preparation and application thereof

An organosilicon cross-linking agent, organosilicon technology, applied in textile and papermaking, fiber processing, liquid/gas/vapor textile processing, etc., can solve problems such as danger, high price, poor durability, etc. Resilience, wide application value and prospect, effect of plump hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

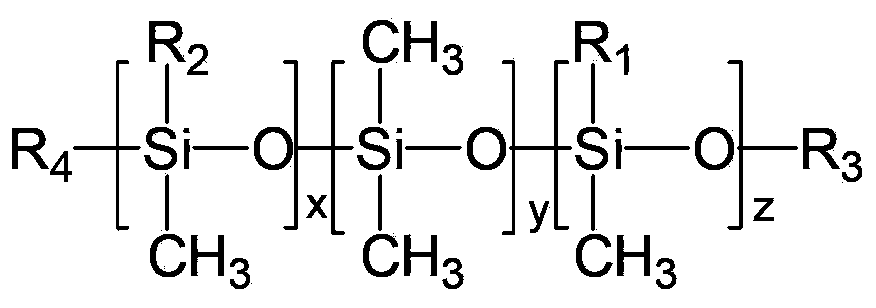

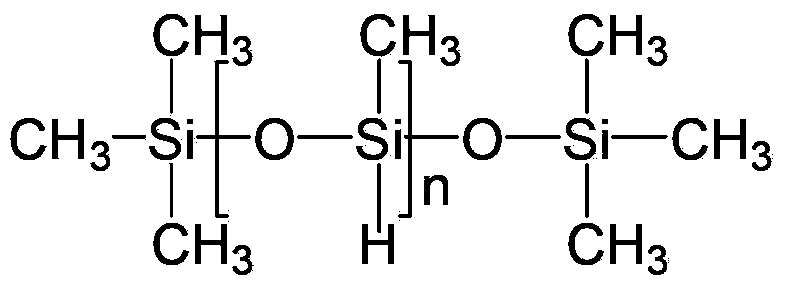

Method used

Image

Examples

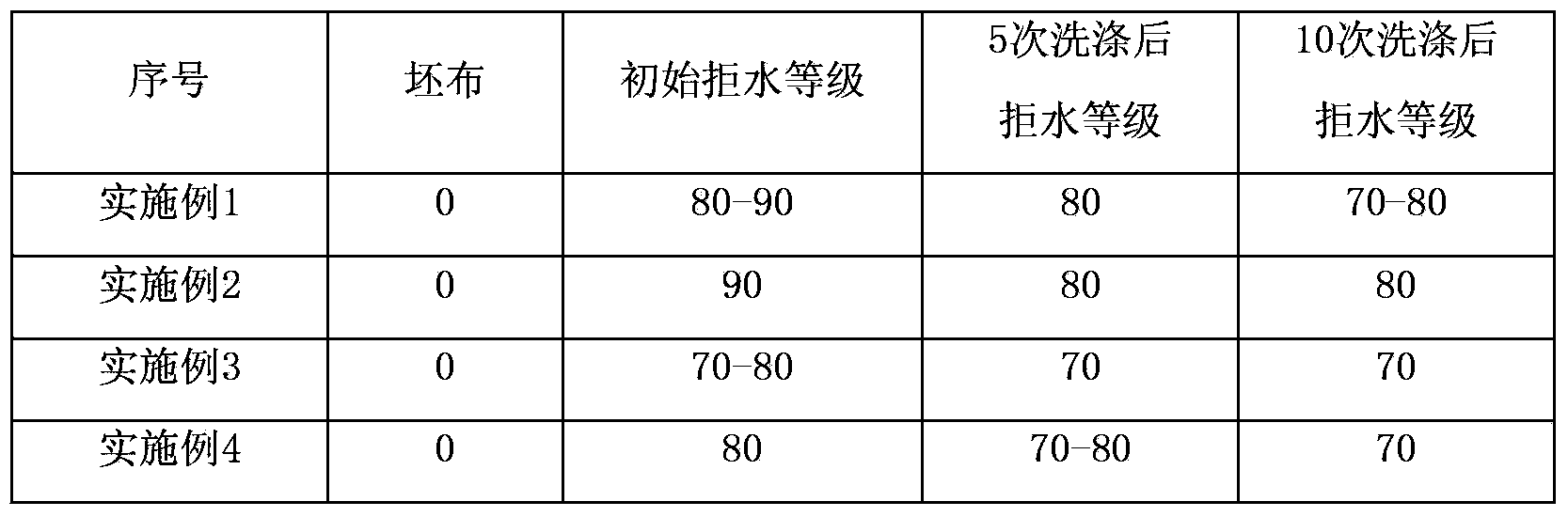

Embodiment 1

[0036] Mix 60 g of self-crosslinking silicone finishing agent, 12 g of silicone crosslinking agent, and 0.04 g of sodium hydroxide, add deionized water at room temperature, stir evenly and set the volume to 1 L to prepare silicone water repellent.

[0037] The process parameters of water-repellent finishing are: the fabric used is white poplin, the liquid carrying rate of the fabric is 70%, the baking temperature is 170°C, and the baking time is 60s.

Embodiment 2

[0039] Mix 80 g of self-crosslinking silicone finishing agent, 20 g of silicone crosslinking agent, and 0.1 g of sodium carbonate, add deionized water at room temperature, stir evenly and set the volume to 1 L to prepare silicone water repellent.

[0040]The process parameters of water-repellent finishing are: the fabric used is polyester taffeta, the liquid carrying rate of the fabric is 30%, the baking temperature is 160°C, and the baking time is 120s.

Embodiment 3

[0042] Mix 40 g of self-crosslinking silicone finishing agent, 7 g of silicone crosslinking agent, and 0.01 g of ammonia water, add deionized water at room temperature, stir evenly and set the volume to 1 L to prepare silicone water repellent agent.

[0043] The process parameters of water-repellent finishing are: the fabric used is nylon, the liquid carrying rate of the fabric is 30%, the baking temperature is 190°C, and the baking time is 25s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com