Two-staged turbocharging system testing device and testing method

A technology of turbocharging system and testing device, which is applied in the direction of internal combustion engine testing, machine/engine, internal combustion piston engine, etc., and can solve the problem of single supercharging control means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

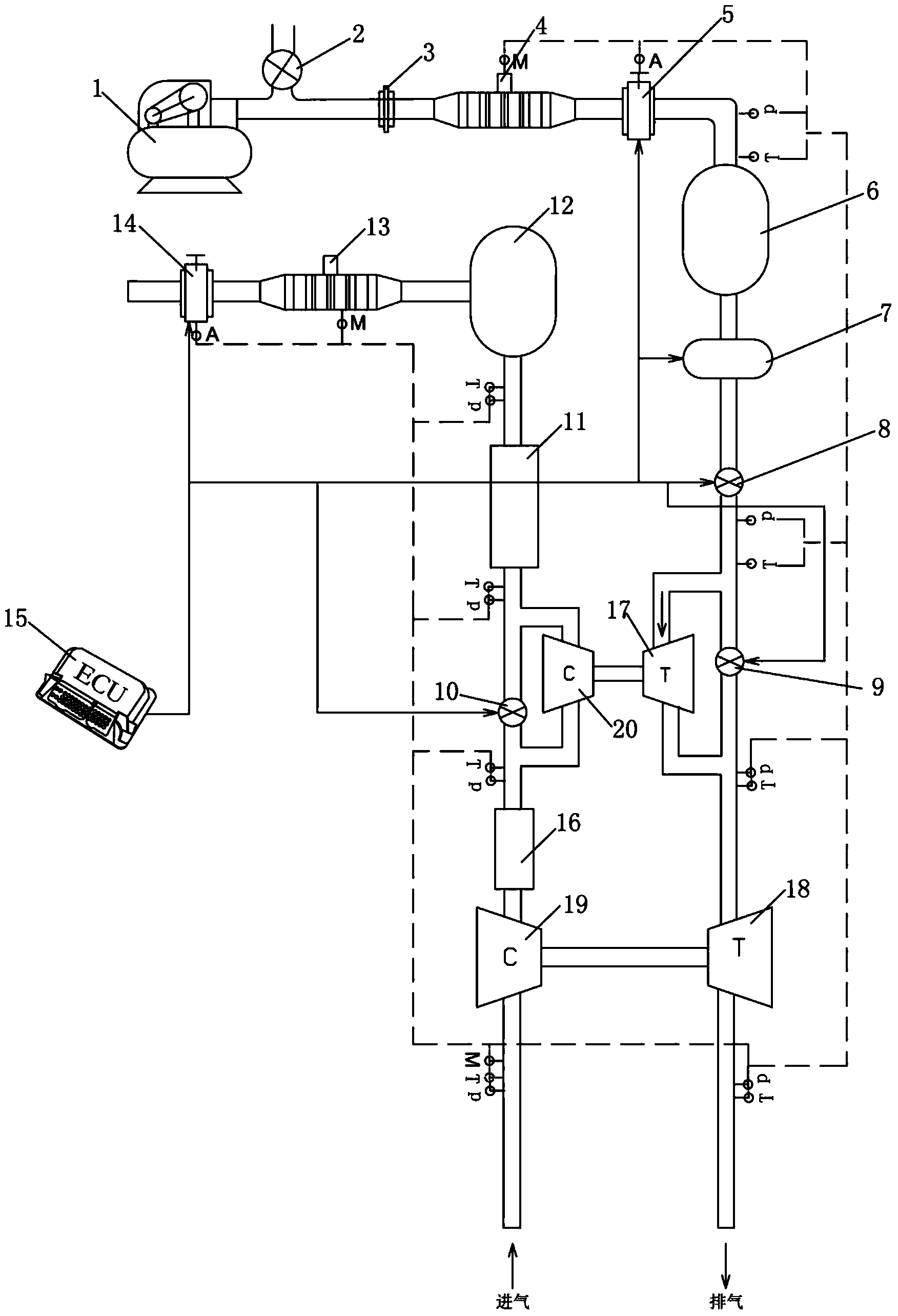

[0016] The special platform for the two-stage supercharging system developed by this device is mainly divided into three parts: the analog supercharging system, the electronic control system 15, and the data acquisition system. Among them, the simulated supercharging system mainly includes air compressor, air release valve, filter tank, intake regulating valve, pressure regulator tank, intake pressure regulating valve, back pressure regulating valve, heater (using electric heater), Compressor and intercooler, pressure side bypass channel and bypass valve, vortex end bypass channel and bypass valve, and sensors such as rotation angle sensors, laminar flow meters, transient temperature sensors, and transient pressures that meet precision requirements are installed on the platform ; The data acquisition and analysis system developed by the platform is implemented by Labview software, which meets the needs of platform development, acquisition, testing and analysis. Various valves o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com