Mechanical seal with two-stage staggered hydrodynamic grooves

A fluid dynamic pressure and mechanical sealing technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problem of not verifying the end face opening performance and sealing ability of the end face structure, not solving the wear of particles on the dynamic pressure groove, and not having good performance. The ability to excrete particles and other issues can enhance the effect of convective heat transfer, improve friction and lubrication, and enhance the dynamic pressure effect and pumping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The double-stage dynamic pressure groove and flow guide groove 3 in the present invention are all opened on the mechanical seal dynamic ring, and the end surface modification can be processed by electric spark, electrochemical corrosion, laser processing and other processes.

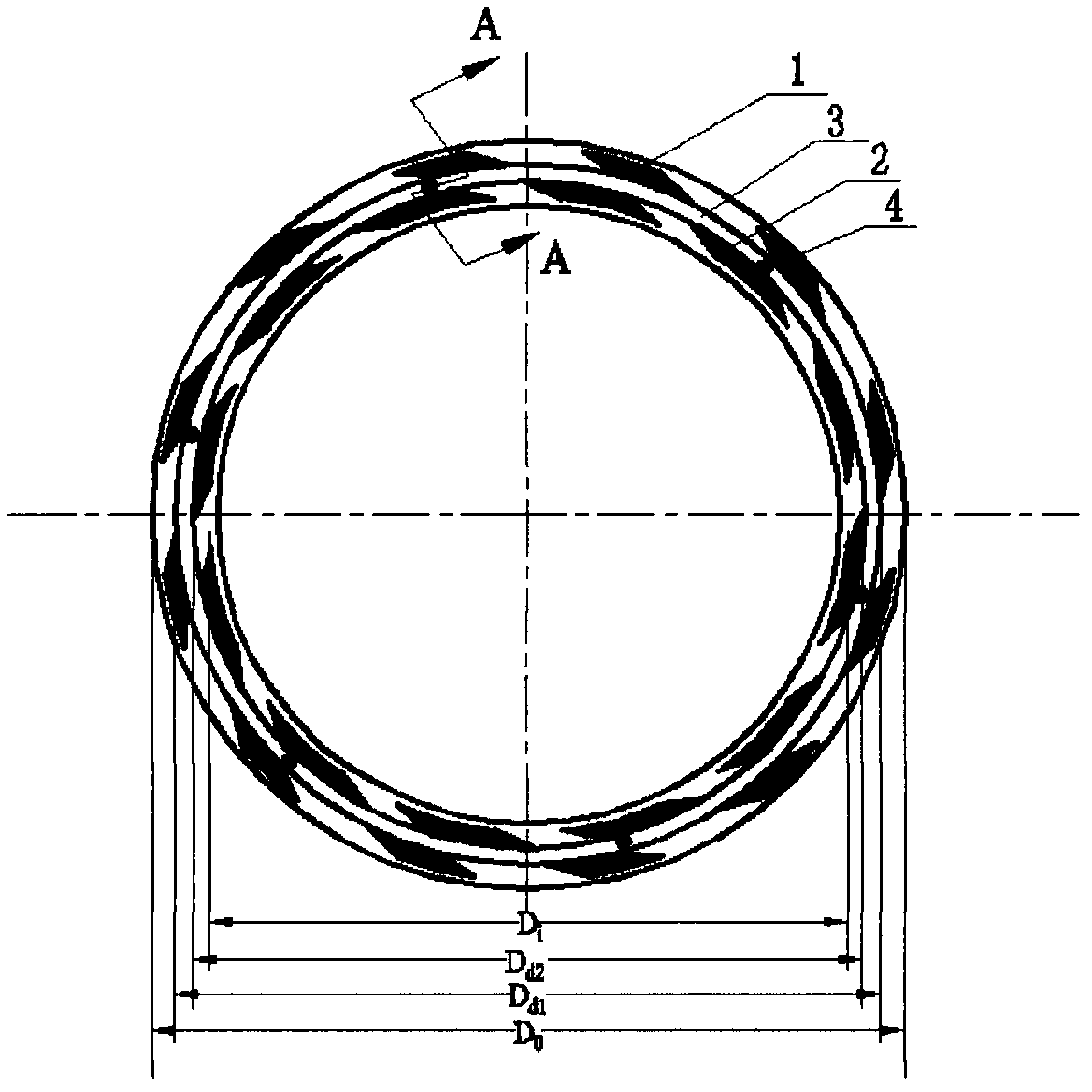

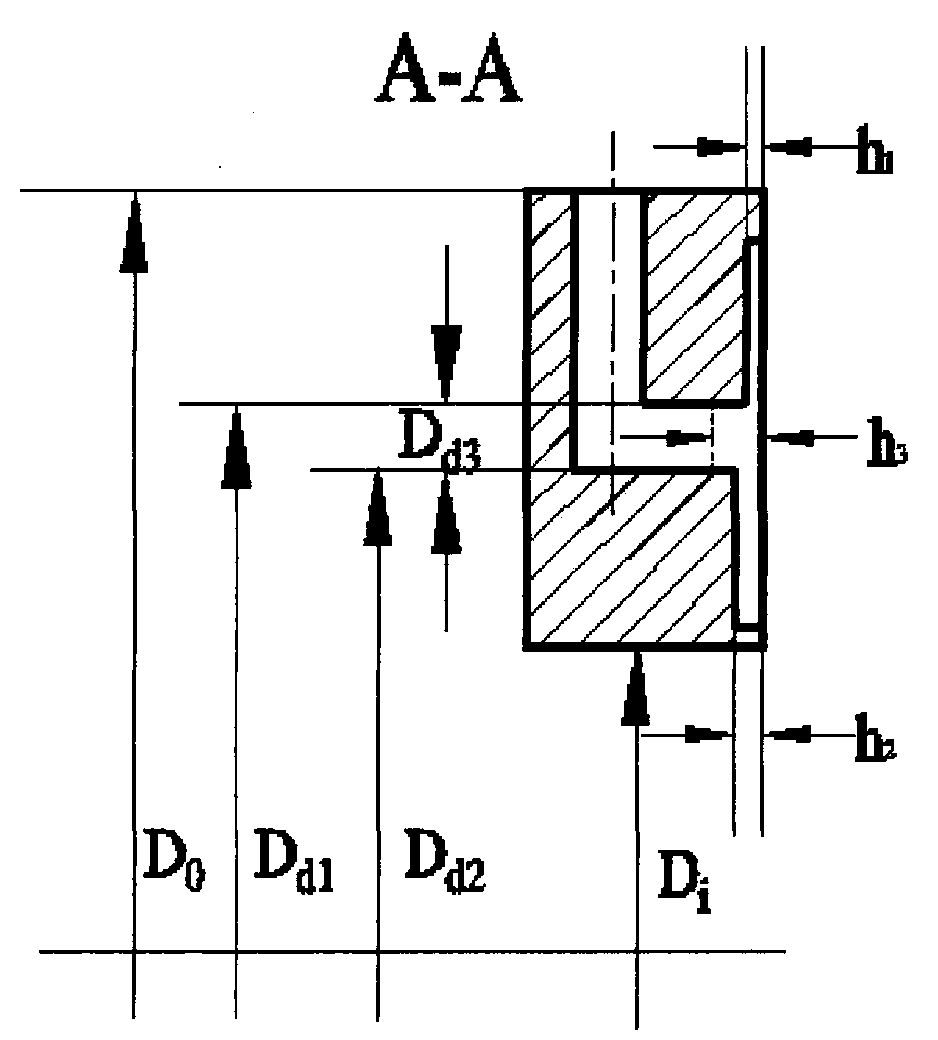

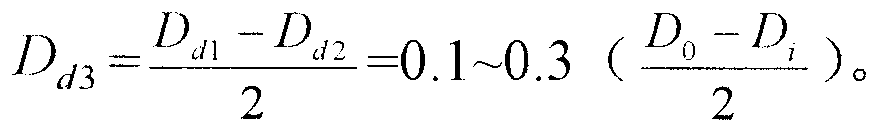

[0012] The first-stage dynamic pressure groove 1, the diversion groove 3 and the second-stage dynamic pressure groove 2, which are symmetrically distributed in the circumferential direction, are set up in the radial direction on the end face of the dynamic ring of the mechanical seal. The diversion groove 3 and the double-stage dynamic pressure groove are respectively connected connection, such as figure 1 As shown, the shape line of the two-stage dynamic pressure groove is a logarithmic helix, the helix angle θ=21°, the width ratio of the groove and weir γ=1.5, and the first-stage dynamic pressure groove is 1 groove deep h 1 =3μm, second stage dynamic pressure groove 2 groove depth h 2 =5μm, gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com