System and method for detecting CO gas based on quartz tuning fork enhanced photoacoustic spectrometry technology

A gas detection system, quartz tuning fork technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problem of low detection accuracy, avoid wavelength drift, improve quality factor, and enhance resistance to environmental low-frequency noise interference effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

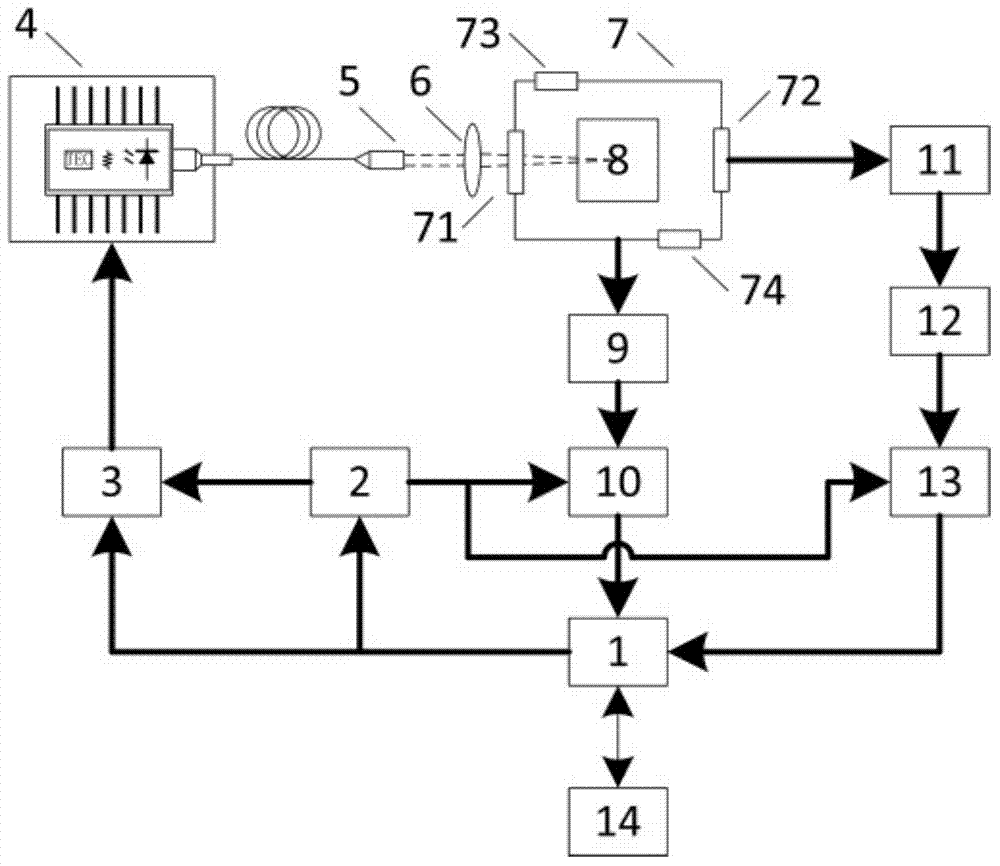

[0034] Specific embodiments 1. A CO gas detection system based on quartz tuning fork enhanced photoacoustic spectroscopy technology, including a data processing module, a laser source module and a photoacoustic signal detection module,

[0035] Data processing module comprises preamplifier 9, the first lock-in amplifier 10, the second lock-in amplifier 13, data acquisition card 1 and computer 14;

[0036] The laser source module includes a function generator 2, a laser controller 3, a laser 4, an optical fiber collimator package 5 and a focusing lens 6;

[0037]The photoacoustic signal detection module includes a gas chamber 7, a quartz tuning fork 8, a reference gas chamber 11 and a photodetector 12; the quartz tuning fork 8 is located in the gas chamber 7, and the gas chamber 7 is filled with CO gas; the reference gas chamber 11 Filled with CO gas;

[0038] The data acquisition card 1 connects the current control signal output end with the current control signal input end o...

specific Embodiment approach 2

[0057] Embodiment 2. The difference of the CO gas detection system based on quartz tuning fork enhanced photoacoustic spectroscopy according to Embodiment 1 is that the optical fiber collimation package 5 and the focusing lens 6 are located on the same optical path.

specific Embodiment approach 3

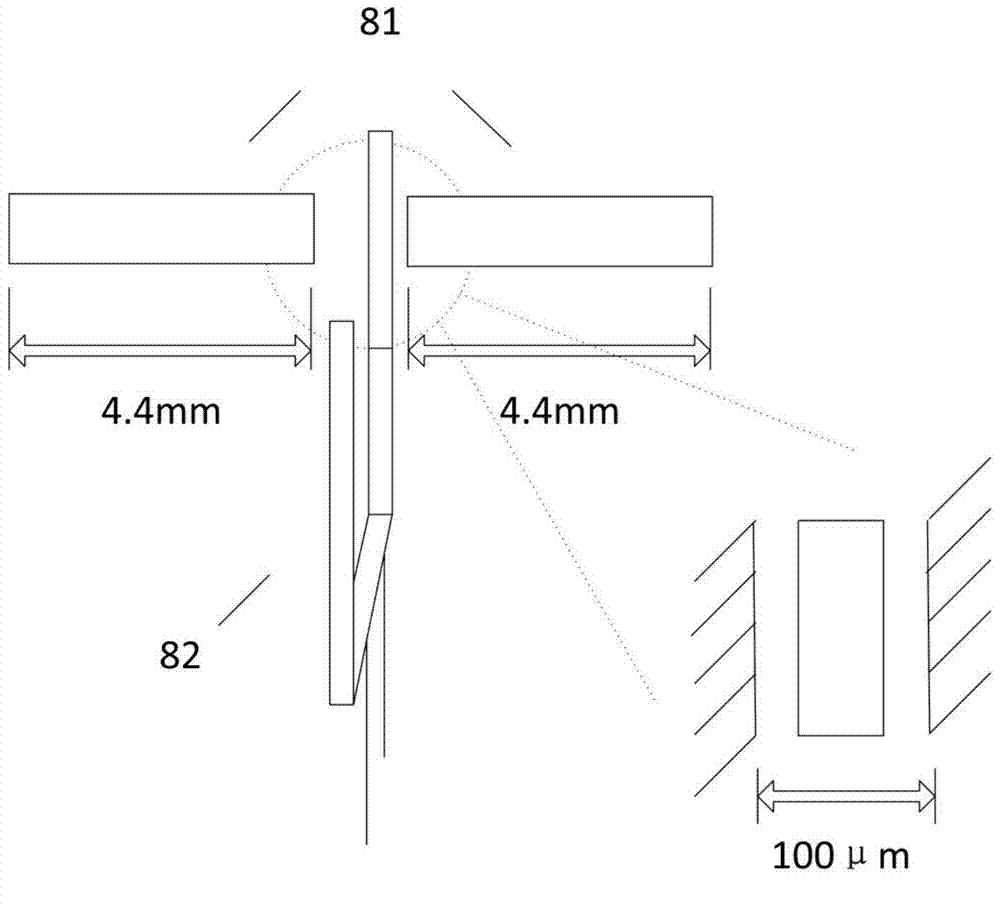

[0058] Embodiment 3. According to Embodiment 2, the difference of the CO gas detection system based on quartz tuning fork enhanced photoacoustic spectroscopy technology is that the reference gas chamber 7 is a cuboid structure;

[0059] Its left side wall and right side wall are respectively provided with laser incident window 71 and laser exit window 72, and the upper end of laser incident window 71 and the upper end of laser exit window 72 are both inclined to the air chamber, and are all in line with the vertical direction. The angles formed are all 5°~7°; the incident window 71 and the exit window 72 are on the optical path described in claim 2;

[0060] An air inlet 73 and an air outlet 74 are respectively opened on the upper surface and the lower surface of the reference air chamber 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com