Analytical method for measuring contents of iron, manganese, aluminum, titanium, nickel, calcium and magnesium in silica powder

A technology of magnesium and silicon powder, used in the analysis of titanium, nickel, magnesium, aluminum, calcium, determination of iron and manganese in silicon powder, can solve the technical conditions and safety requirements for increasing magnesium detection and not suitable for scientific research and production And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

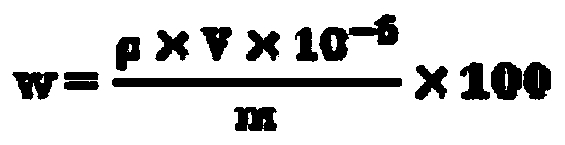

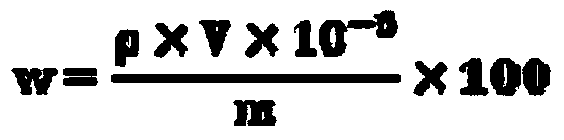

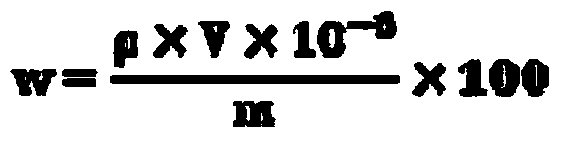

Image

Examples

Embodiment 1

[0066] To measure the content of iron, manganese, aluminum, titanium, nickel, calcium and magnesium in silicon powder, an inductively coupled plasma emission spectrometer (French JY170) is used. The working conditions and analysis lines of the instrument are as follows: high frequency frequency: 40.68MHz ;Incidental power: 0.95Kw; Reflected power: <15W; Cooling air flow: 15L / min; Sheath air flow: 0.2L / min; Mn: 257.610nm; Al: 396.152nm; Ti: 334.941nm; Ni: 231.604nm; Ca: 315.887nm; Mg: 285.213nm.

[0067] The reagents used in the assay process are as follows:

[0068] Hydrochloric acid, ρ1.19g / mL; superior grade;

[0069] Hydrochloric acid, 1+1;

[0070] Hydrofluoric acid, ρ1.14g / mL; superior grade;

[0071] Nitric acid, ρ1.42g / mL; superior grade;

[0072] Nitric acid, 1+1;

[0073] Sulfuric acid, ρ1.84g / mL; superior grade;

[0074] Sulfuric acid, 1+1;

[0075] Iron standard solution A: the mass-volume concentration is 1.00mg / mL, the preparation method is to weigh 0.5000g...

Embodiment 2

[0107] To measure the content of iron, manganese, aluminum, titanium, nickel, calcium and magnesium in silicon powder, an inductively coupled plasma emission spectrometer (French JY170) is used. The working conditions and analysis lines of the instrument are as follows: high frequency frequency: 40.68MHz ; Incident power: 1.0Kw; Reflected power: <15W; Cooling air flow: 18L / min; Sheath air flow: 0.4L / min; Sample lift: 1.2mL / min; Integration time: 8s; Elemental analysis line: Fe Mn: 257.610nm; Al: 396.152nm; Ti: 334.941nm; Ni: 231.604nm; Ca: 315.887nm; Mg: 279.553nm.

[0108] The reagents used in the assay process are as follows:

[0109] Hydrochloric acid, ρ1.19g / mL; superior grade;

[0110] Hydrochloric acid, 1+1;

[0111] Hydrofluoric acid, ρ1.14g / mL; superior grade;

[0112] Nitric acid, ρ1.42g / mL; superior grade;

[0113] Nitric acid, 1+1;

[0114] Sulfuric acid, ρ1.84g / mL; superior grade;

[0115] Sulfuric acid, 1+1;

[0116] Iron standard solution A: the mass-volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com