Cobaltosic oxide-zinc oxide/grapheme ternary complex and preparation method thereof

A technology of tricobalt tetroxide and ternary composites, which is applied in the direction of cobalt oxide/cobalt hydroxide, zinc oxide/zinc hydroxide, and electrochemical variables of materials, which can solve the problem of reducing material performance, poor selectivity of specific gas response, and easy occurrence of nanoparticles Agglomeration and other problems, to achieve the effect of preventing agglomeration, excellent gas-sensing performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

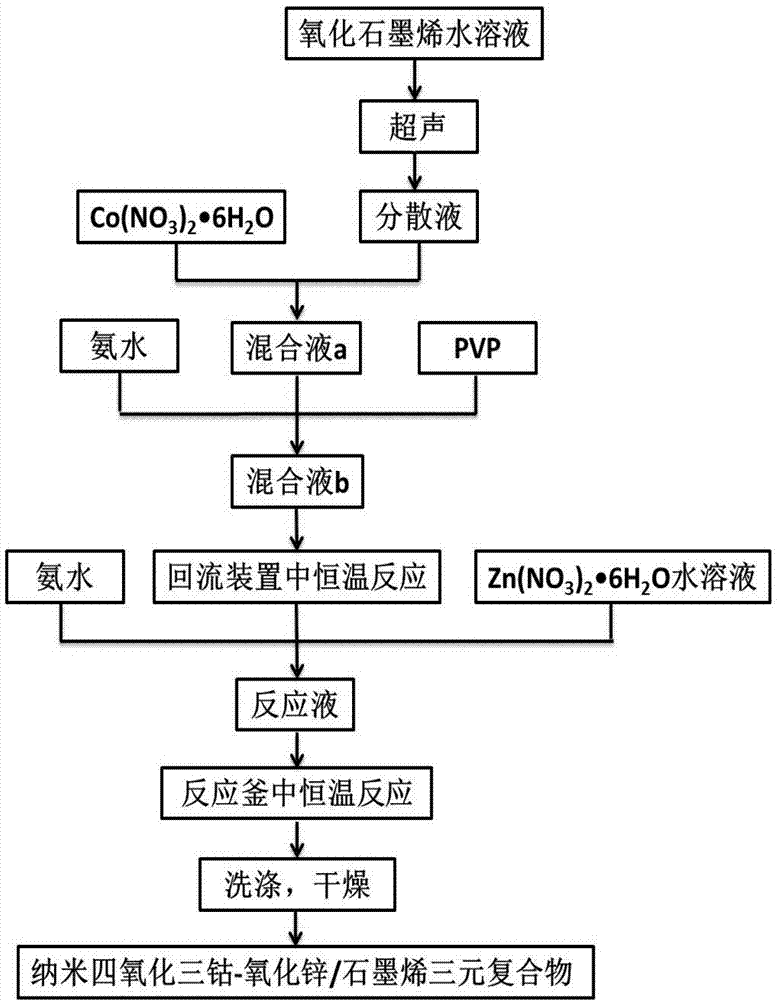

[0033] combine figure 1 , the preparation method of a kind of tricobalt tetroxide-zinc oxide / graphene ternary compound of the present invention, specifically comprises the following steps:

[0034] Step 1: ultrasonically treating the graphene oxide aqueous solution to obtain a uniform dispersion;

[0035]Step 2: Co(NO 3 ) 2 ·6H 2 O is added to the dispersion in step 1 to obtain a mixed solution a;

[0036] Step 3: adding ammonia water and surfactant PVP to the mixed solution a in step 2 to obtain the mixed solution b;

[0037] Step 4: reacting the mixed solution b in step 3 at a constant temperature in a reflux device;

[0038] Step 5: After the reflux reaction finishes, Zn(NO 3 ) 2 ·6H 2 O, ammoniacal liquor are mixed with step 4 mixed solution b to form a reaction solution;

[0039] Step 6: The above-mentioned reaction solution is reacted at a constant temperature in a closed reaction kettle; the product is washed and dried to obtain a nano-cobalt oxide-zinc oxide / g...

Embodiment 1

[0050] Step 1: 35ml of graphene oxide aqueous solution (0.2mg / ml) was ultrasonically treated for 60min to obtain a uniform dispersion;

[0051] Step 2: 0.875gCo(NO 3 ) 2 ·6H 2 O is added to the dispersion in step 1 to obtain a mixed solution a;

[0052] Step 3: Add 30ml of ammonia water (concentration: 28wt%) and 0.1g of PVP surfactant into the mixed solution a in step 2 to obtain the mixed solution b;

[0053] Step 4: React the mixed liquid b in step 3 at a constant temperature in a reflux device, the reaction temperature is 100°C, and the reaction time is 6h;

[0054] Step five: after the reflux reaction finishes, 0.301g Zn(NO 3 ) 2 ·6H 2 0, 5ml ammoniacal liquor (concentration is 28wt%) mixes with step 4 mixed solution b, forms reaction solution;

[0055] Step 6: The above-mentioned reaction solution was reacted at a constant temperature in a closed reaction kettle, the reaction temperature was 180° C., and the reaction time was 18 hours; the product was washed and d...

Embodiment 2

[0058] Step 1: 35ml of graphene oxide aqueous solution (1.5mg / ml) was ultrasonically treated for 10min to obtain a uniform dispersion;

[0059] Step 2: 0.525gCo(NO 3 ) 2 ·6H 2 O is added to the dispersion in step 1 to obtain a mixed solution a;

[0060] Step 3: Add 30ml of ammonia water (concentration: 20wt%) and 0.014g of PVP surfactant into the mixed solution a in step 2 to obtain mixed solution b;

[0061] Step 4: React the mixed liquid b in Step 3 at a constant temperature in a reflux device, the reaction temperature is 80°C, and the reaction time is 3h;

[0062] Step five: after the reflux reaction finishes, 1.3125gZn(NO 3 ) 2 ·6H 2 0, 5ml ammoniacal liquor (concentration is 20wt%) mixes with step 4 mixed solution b, forms reaction solution;

[0063] Step 6: The above-mentioned reaction solution was reacted at a constant temperature in a closed reaction kettle, the reaction temperature was 150° C., and the reaction time was 48 hours; the product was washed and drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com