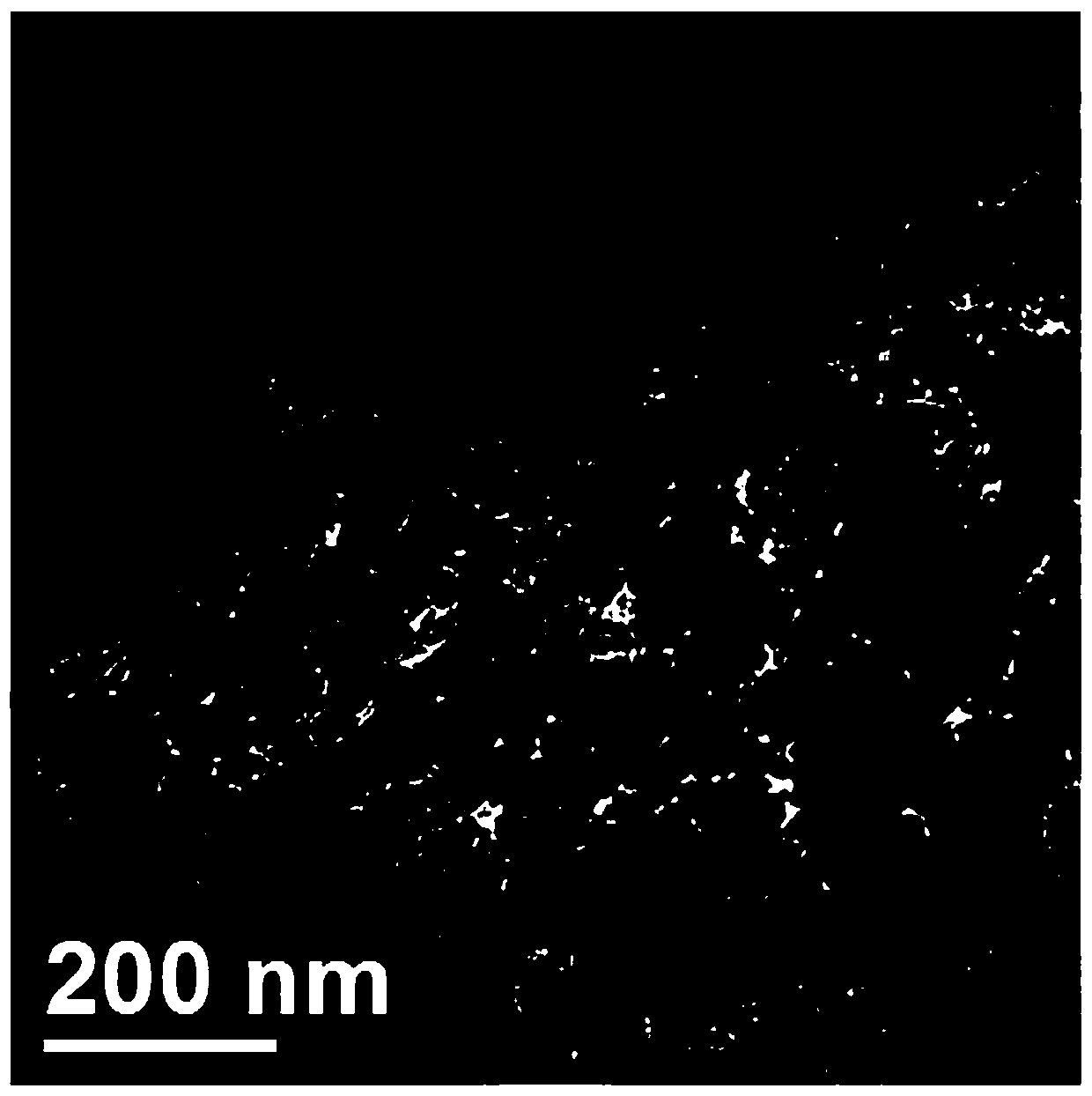

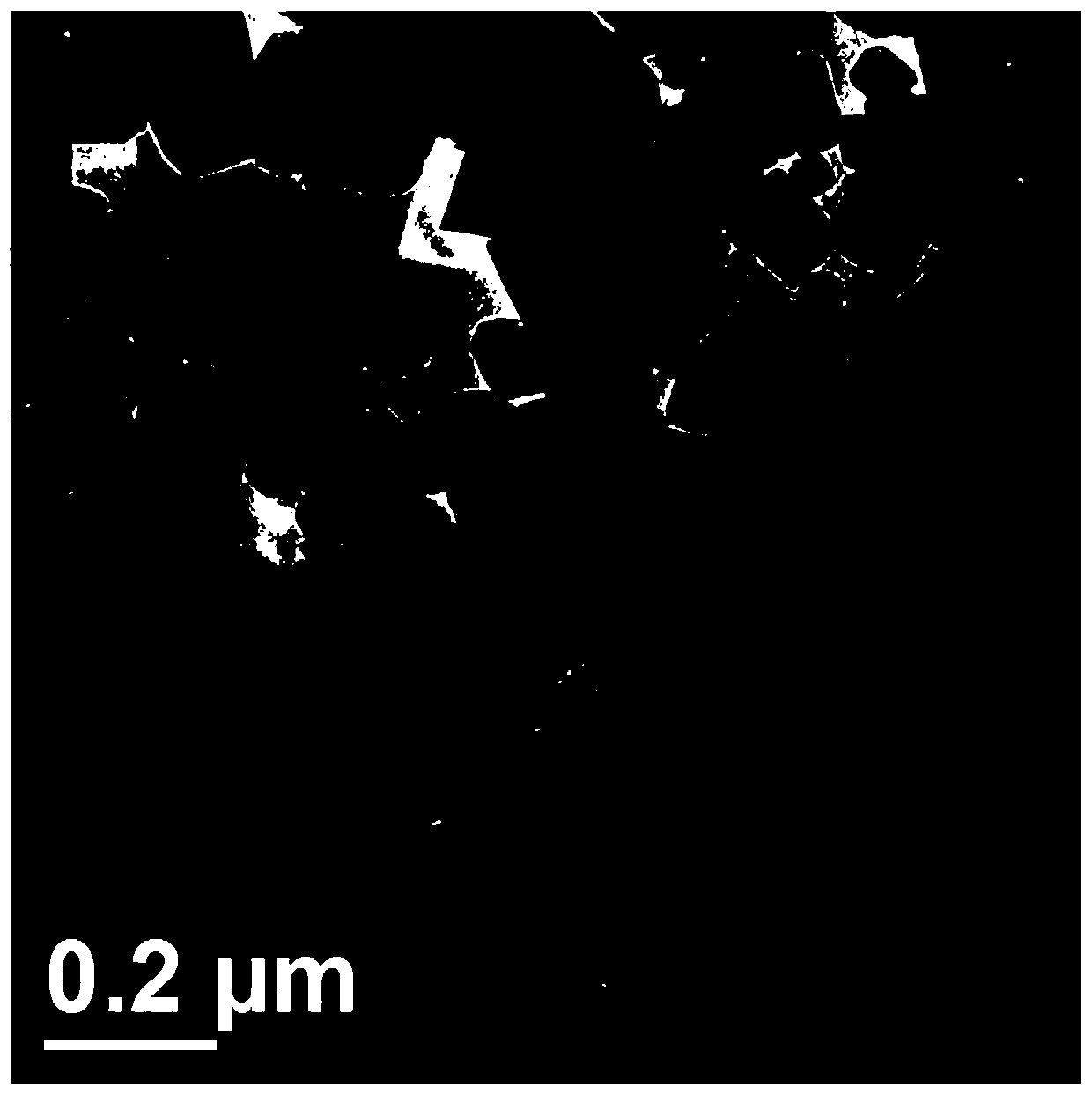

Graphene-supported ferroferric oxide magnetic powder particles and preparation method thereof

A technology of ferromagnetic tetroxide and graphene, applied in the direction of graphene, iron oxide/ferric hydroxide, ferrous oxide, etc., can solve the problem of reducing detection sensitivity, repeated utilization of magnetic powder, and easy agglomeration of nanoparticles. , increase the coercivity and remanence, etc., to achieve the effect of excellent suspension, good application prospects, and increased dispersion and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) After mixing 0.3 g of ferric chloride hexahydrate, 0.5 g of ferric dichloride tetrahydrate, 0.5 g of sodium hydroxide, and 10 ml of graphene oxide aqueous solution (containing 20 mg of graphene oxide) with a concentration of 2 mg / ml Ultrasonic treatment was carried out for 120 minutes to obtain a uniform mixed solution A;

[0029] (2) Put the mixed solution A under constant temperature reflux for reaction, the reaction temperature is 25°C, the generated ferric hydroxide and ferrous hydroxide gradually grow as nuclear particles, and the reaction time is 0.5h; then 1ml concentration is 10wt% Aqueous ammonia is added to the reaction system to obtain a mixed solution B;

[0030] (3) Continue to react the mixed solution B under constant temperature reflux, the reaction temperature is 75°C, and the reaction is completed after reflux for 2 hours, and the reaction solution is obtained;

[0031] (4) Centrifuge the reaction solution to obtain solid matter, and dry it in a va...

Embodiment 2

[0034] (1) After mixing 0.3 g of ferric chloride hexahydrate, 0.5 g of ferric dichloride tetrahydrate, 0.5 g of sodium hydroxide, and 5 ml of a graphene oxide aqueous solution (containing 10 mg of graphene oxide) with a concentration of 2 mg / ml Perform ultrasonic treatment for 60 minutes to obtain a uniform mixed solution A;

[0035] (2) Put the mixed solution A under constant temperature reflux for reaction, the reaction temperature is 40°C, the generated ferric hydroxide and ferrous hydroxide gradually grow as nuclear particles, and the reaction time is 1h; then add 2ml of 28wt% Add ammonia water to the reaction system to obtain mixed solution B;

[0036] (3) Continue to react the mixed solution B under constant temperature reflux, the reaction temperature is 100°C, and the reaction is completed after reflux for 3 hours to obtain the reaction solution;

[0037] (4) Centrifuge the reaction solution to obtain a solid, and dry it in a vacuum oven at 40°C after washing to obtai...

Embodiment 3

[0040](1) After mixing 0.3 g of ferric chloride hexahydrate, 0.5 g of ferric dichloride tetrahydrate, 0.5 g of sodium hydroxide, and 10 ml of a graphene oxide aqueous solution (containing 30 mg of graphene oxide) with a concentration of 3 mg / ml Ultrasonic treatment was carried out for 150 minutes to obtain a uniform mixed solution A;

[0041] (2) Put the mixed liquid A under constant temperature reflux for reaction, the reaction temperature is 30°C, the generated ferric hydroxide and ferrous hydroxide gradually grow as nuclear particles, and the reaction time is 0.75h; then 3ml concentration is 20wt% Aqueous ammonia is added to the reaction system to obtain a mixed solution B;

[0042] (3) Continue to react the mixed solution B under constant temperature reflux, the reaction temperature is 50°C, and the reaction is completed under reflux for 1 hour to obtain the reaction solution;

[0043] (4) Centrifuge the reaction solution to obtain a solid, and dry it in a vacuum oven at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com