High-Voltage Cascode Diodes with High Electron Mobility Transistors and Monolithically Integrated Semiconductor Diodes

A diode and semiconductor technology, applied in the field of high-voltage diodes, can solve the problems of reducing the parasitic inductance and capacitance of cascaded circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

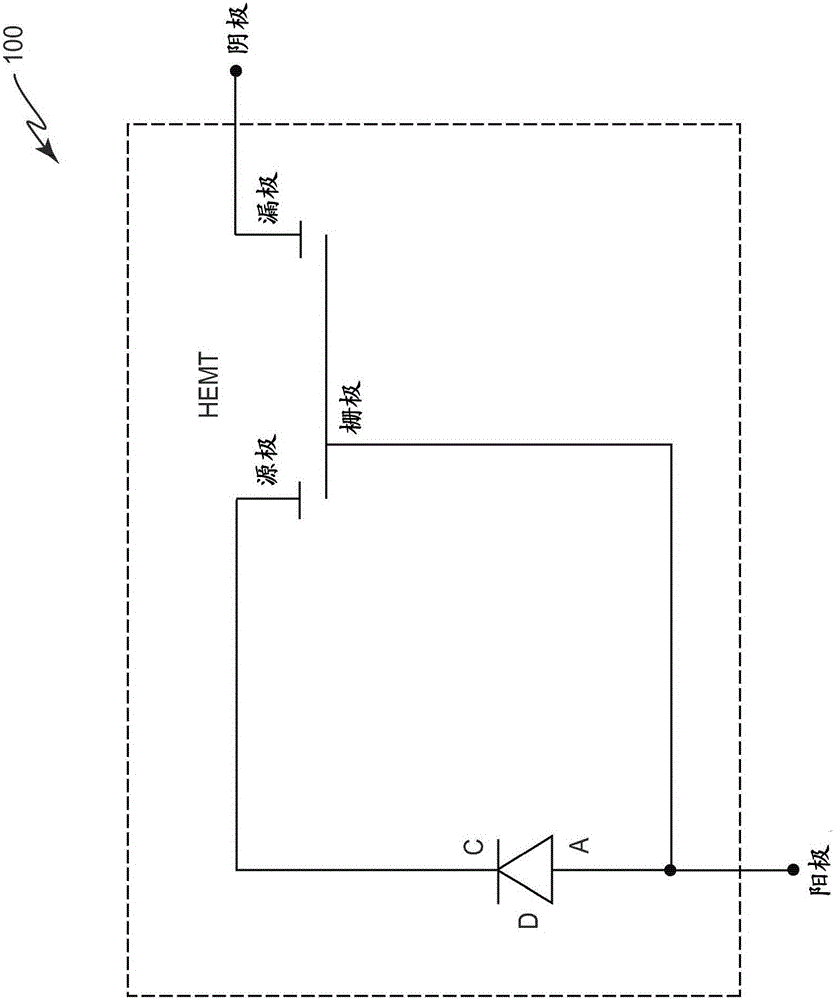

[0019] figure 1 A schematic diagram of a cascaded diode 100 is shown. Such as figure 1 As indicated by the dashed box in , the cascode diode 100 includes a HEMT and a semiconductor diode (D) monolithically integrated with the HEMT on the same die. The cathode (C) of the semiconductor diode is connected to the source (S) of the HEMT and the anode (A) of the semiconductor diode is connected to the gate (G) of the HEMT. The anode of the semiconductor diode forms the anode (“anode”) of the cascode diode 100 and the drain (D) of the HEMT forms the cathode (“cathode”) of the cascode diode 100 . Such monolithically integrated configurations result in cascode diode 100 with the advantages of low threshold voltage of semiconductor diodes and the advantages of high current density and high breakdown voltage of HEMTs, while eliminating undesired Parasitic package inductance and capacitance.

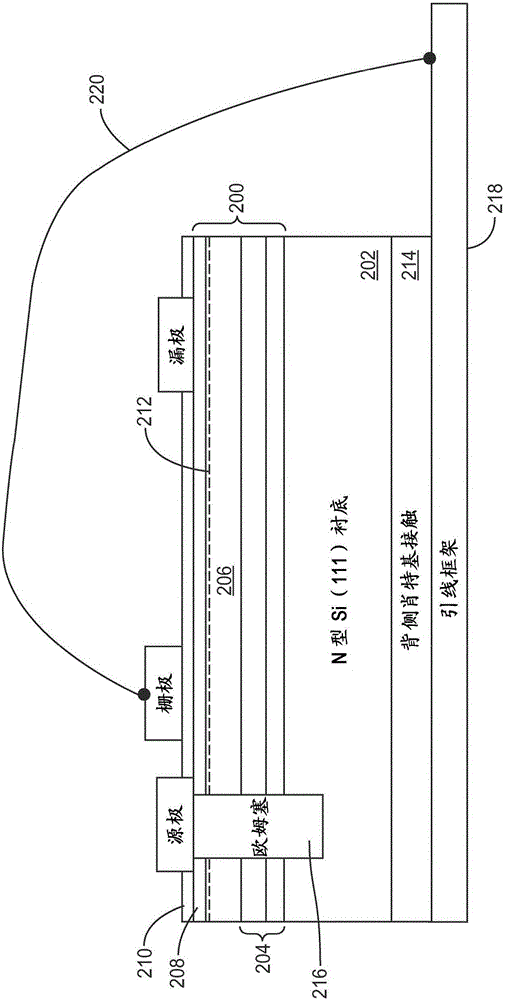

[0020] In general, HEMTs can be implemented using any suitable Ill-nitride technology, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com