Method for preparing sulphur-supported porous carbon lithium battery electrode material by using waste polyurethane plastic

A technology of electrode material and porous carbon, which is applied in the field of preparation of electrode materials for lithium-ion power batteries, can solve problems such as harsh experimental conditions, failure to realize large-scale commercial production, and complicated preparation methods, and achieve mild experimental conditions and excellent preparation methods. The effect of simplicity and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention are described below.

[0021] A method for preparing a porous carbon-loaded lithium battery electrode material with waste polyurethane plastics, which has the following process and steps: take 10 g of pulverized waste polyurethane plastics and 30 g of potassium carbonate powder, mix them well, and put them into a porcelain crucible Inside, cover the porcelain crucible, put the crucible into the muffle furnace heated to 800 ℃ in advance, take out the porcelain crucible after reacting for 60 minutes, pour the solid in the porcelain crucible into the boiling water prepared in advance, and boil for 10 minutes . Suction filtration with Buchner funnel, the obtained solid product was repeatedly washed with deionized water until neutral, and dried in an oven for 24 h. Finally, the dried powder was ground into a uniform powder with an agate mortar for later use.

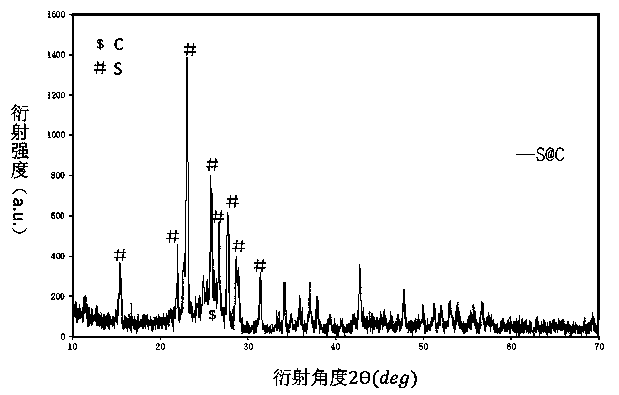

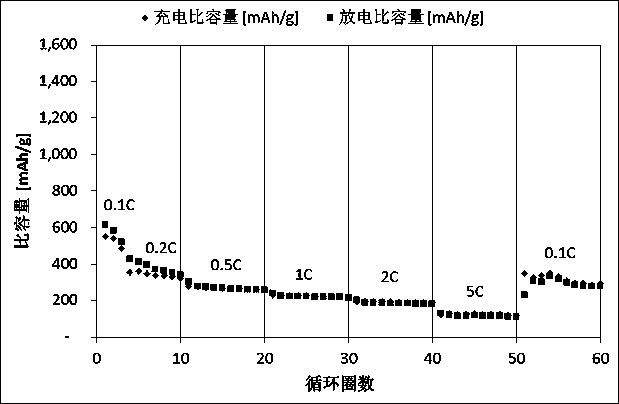

[0022] Take 6 g of sublimated sulfur and 1.5 g of the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com