Catalyst for hydrogenation of oxalate to ethylene glycol and preparation method thereof

A technology of catalyst and oxalate, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, and preparation of organic compounds, etc., can solve the problems of uneven distribution of catalyst particles and low activity, and achieve difficult aggregation and sintering, high catalytic activity, The effect of catalyst performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

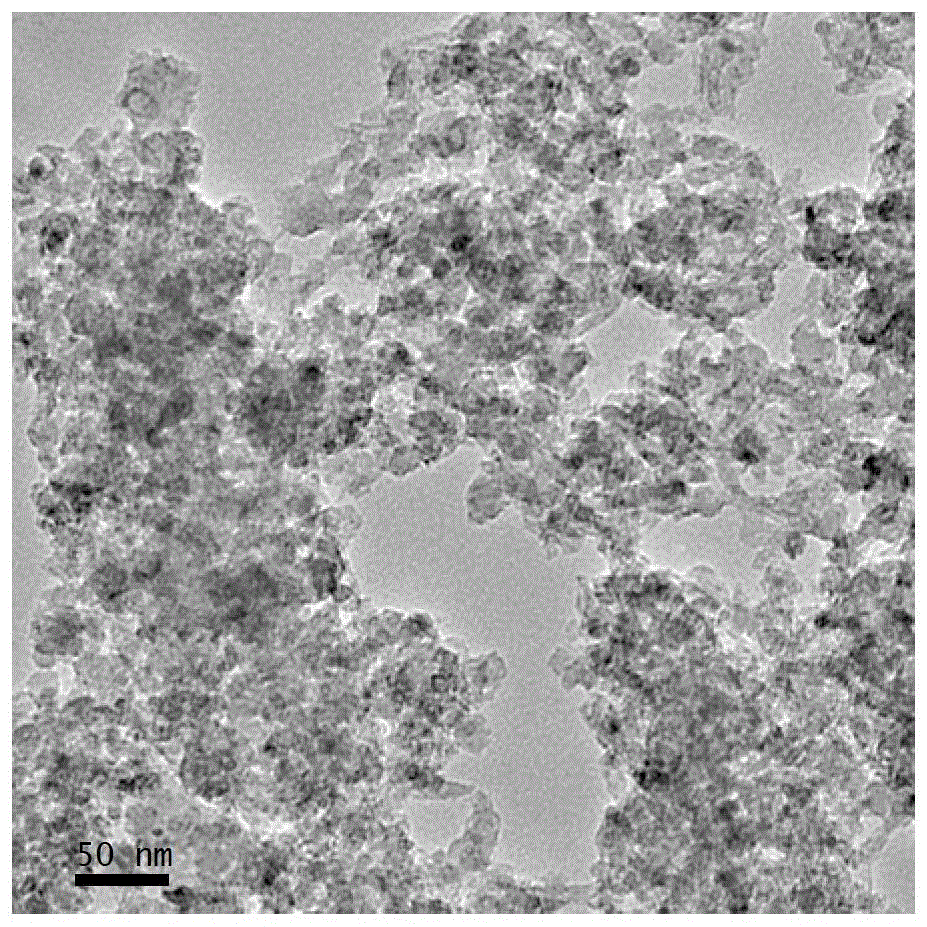

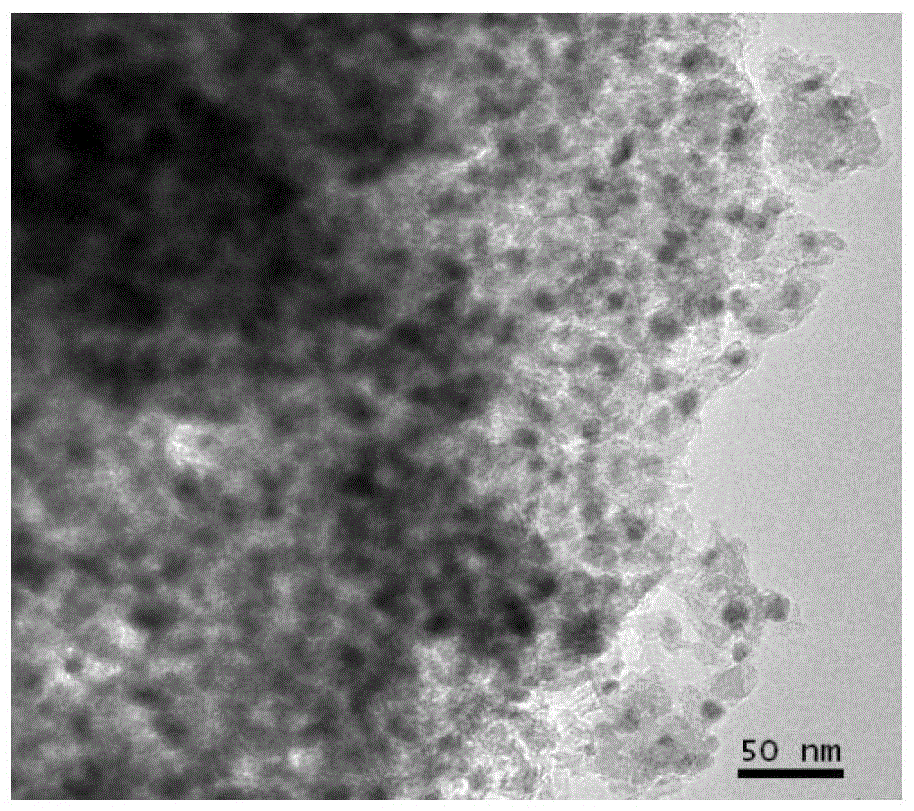

Image

Examples

Embodiment 1

[0050] To 600ml copper nitrate solution (molar concentration is 0.39mol / L), add 150g alkaline silica sol (silicon dioxide content is 30wt%), stir evenly, directly add 25% ammonia water until the pH value of the solution is 11.5, stir After 5 hours, heat to 80°C for reflux reaction until the pH of the solution is 6.0, then filter, wash with water until neutral, and wash with ethanol, then dry the obtained filter cake at 120°C, and roast at 450°C for 5 hours to obtain the catalyst.

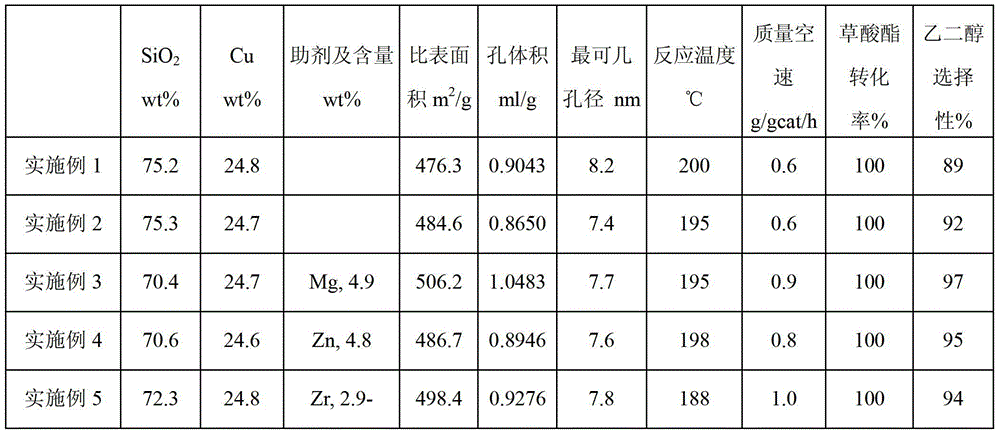

[0051] After the catalyst precursor is pretreated by reduction in a hydrogen-containing atmosphere, the oxalate ester solution (mass fraction 15%) was vaporized and then contacted with a copper-containing catalyst to generate an effluent containing ethylene glycol. The hydrogenation data are shown in Table 1. The reaction result is: the conversion rate of oxalate is 100%, and the selectivity of ethylene glycol is 89%.

Embodiment 2

[0053] The preparation of the catalyst was the same as in Example 1, except that the pH value of the solution was adjusted to 12.

[0054] Catalyst evaluation is the same as in Example 1, except that the reaction temperature is 195° C., and the hydrogenation data are shown in Table 1. The reaction result is: the conversion rate of oxalate is 100%, and the ethanol selectivity is 92%.

Embodiment 3

[0056] To 600ml copper nitrate and magnesium nitrate solution (molar concentration is 0.39mol / L and 0.22mol / L respectively), add 150g alkaline silica sol (silicon dioxide content is 30wt%), stir evenly, slowly add 25% Ammonia water until the pH value of the solution reaches 12, after stirring for 5 hours, heat to 80°C for reflux reaction until the pH value of the solution is 6.0, then filter, wash with water until neutral, and wash with ethanol, and then bake the obtained filter cake at 120°C Dry, and calcined at 450°C for 5h to obtain a hydrogenation catalyst.

[0057] The catalyst evaluation was the same as in Example 1, except that the reaction temperature was 195° C., the mass space velocity was 0.9 g / gcat / h, and the hydrogenation data were shown in Table 1. The reaction result is: the conversion rate of oxalate is 100%, and the selectivity of ethylene glycol is 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com