a kind of sio 2 -al 2 o 3 Preparation method of composite carrier

A technology of composite carrier and mixed solution, applied in catalyst carriers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of catalyst activity decline, catalyst surface texture damage, loss of active components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

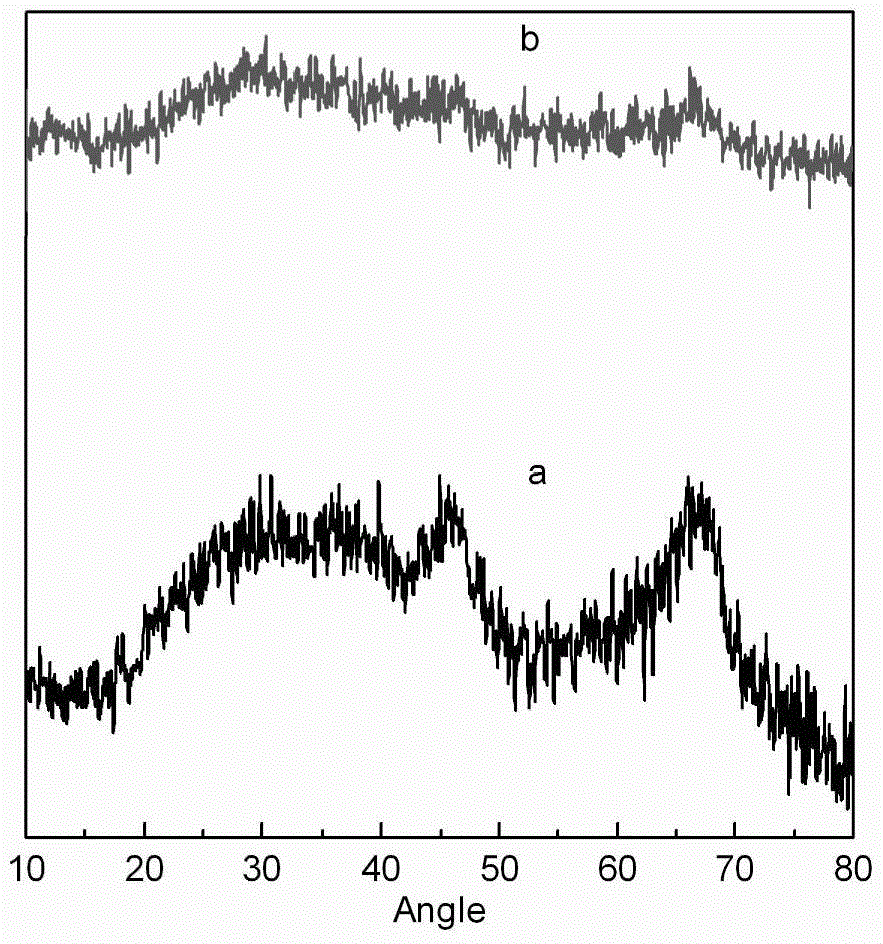

Image

Examples

Embodiment 1

[0016] Weigh 30g of pseudo-boehmite and 100g of water, and beat at room temperature for 3h.

[0017] Prepare the following solution:

[0018] Orthoethyl silicate (TEOS): absolute ethanol: deionized water: concentrated nitric acid = 1:9:2:0.3 (molar ratio) Beaker A: 12.5ml orthoethyl silicate (TEOS) + 15ml absolute ethanol ( The order of writing is the order of addition) Beaker B; 15ml of absolute ethanol + 2ml of deionized water + 1ml of concentrated nitric acid (the order of writing is the order of addition) (the absolute ethanol in beaker A and beaker B are both the required total amount of ethanol half)

[0019] Add the solution in beaker B dropwise to beaker A at a rate of 20ml / min to form a sol, and immediately pour the prepared sol into the beating solution of pseudo-boehmite, stir rapidly for 60min, take it out and put it on a clean watch glass 24h in the air, dried in an oven at 120°C for 3h, and baked in a muffle furnace at 500°C for 4h to obtain a composite carrier...

Embodiment 2

[0023] Only change the composition of the beating liquid, and replace the pseudo-boehmite with γ-Al 2 o 3 , 30g γ-Al 2 o 3 Mix with 100g of water and beat for 3h, the rest of the process is the same as the preparation process of catalyst A, SiO in the composite carrier 2 The mass fraction accounts for 10% of the composite carrier mass fraction, and the preparation of Ni 2 Catalyst Ni with 20% P loading 2 P / SiO 2 -10-γ-Al 2 o 3 , denoted as D.

Embodiment 3

[0025] Change nitric acid into ammonia water, and the rest of the process is the same as the preparation process of catalyst A, and the SiO in the composite carrier 2 The mass fraction accounts for 10% of the composite carrier mass fraction, and the preparation of Ni 2 Catalyst Ni with 20% P loading 2 P / SiO 2 -10-Al 2 o 3 , denoted as E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com