Optical sheet

An optical sheet, a mathematical technology, applied in the field of optical sheets, which can solve problems such as being susceptible to external impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

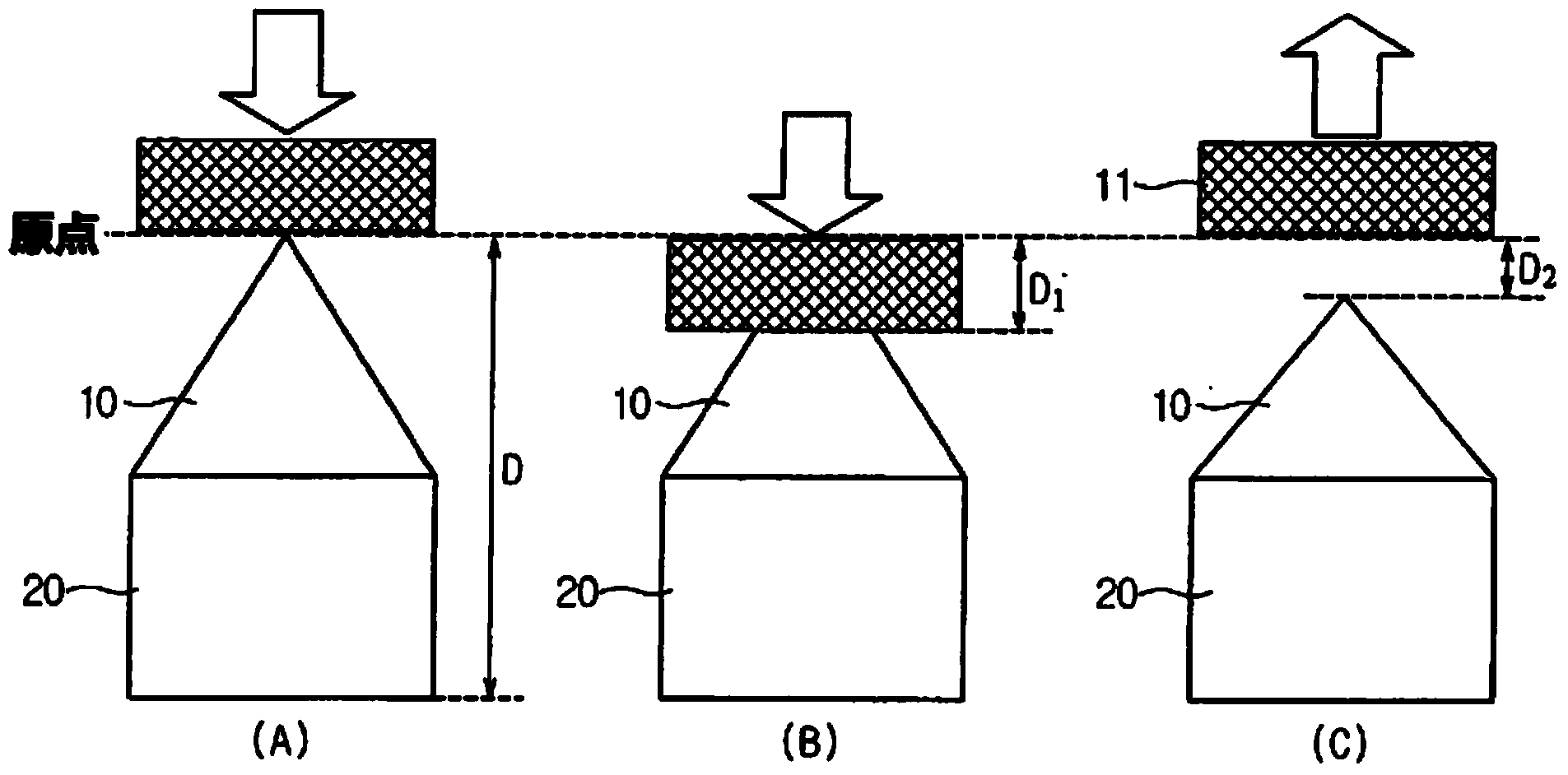

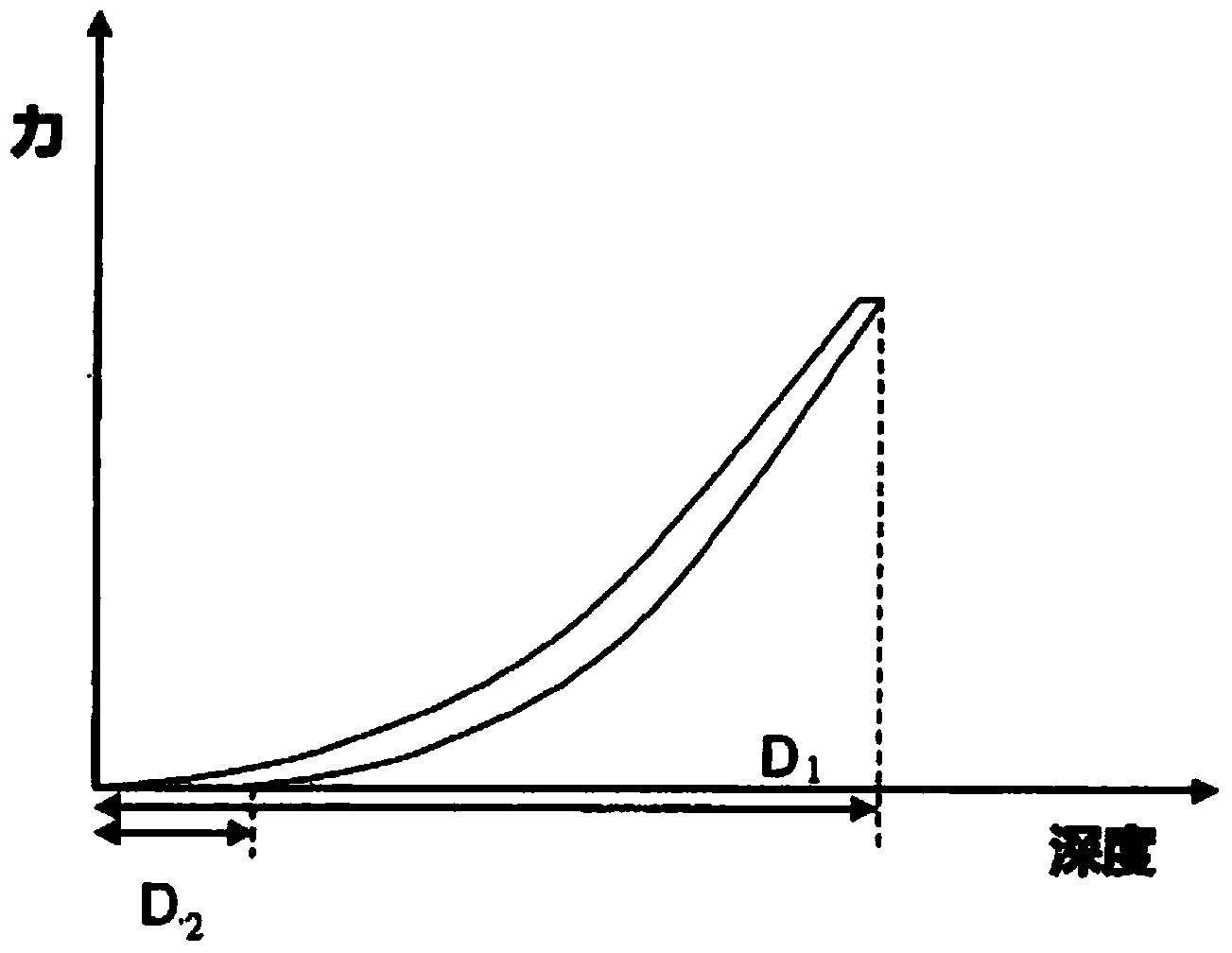

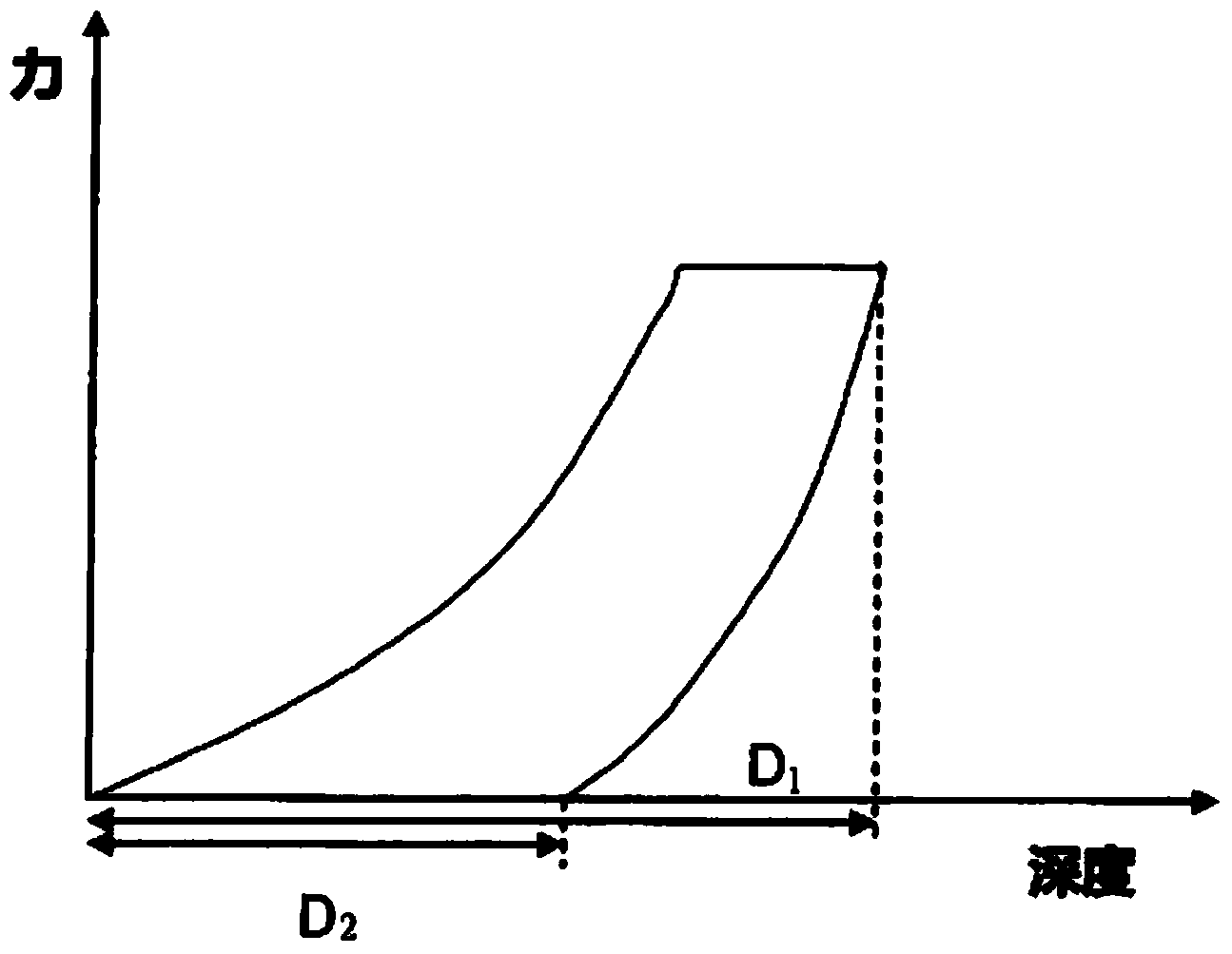

Method used

Image

Examples

Embodiment approach

[0132] Examples of the present invention will be described in detail below, but the present invention is not limited to the following examples.

[0133] Manufacture of Acrylate Oligomers

Synthetic example 1

[0135] Add toluene 500g, triethylamine 14ml, bisphenol A bischloroformate (Aldrich company) 39.3g (0.1 mole) and polyethylene glycol acrylate (Aldrich company, number average molecular weight 375) in the reflux reactor that is full of nitrogen. ) 75.0g (0.2 moles), reacted at 50°C for 24 hours, then separated the generated salt by centrifugation, and then removed the solvent and unreacted substances by distillation under reduced pressure, thereby producing acrylic acid represented by chemical formula 1 Ester oligomer, wherein n=2; R is H; x=2; y=z=0; a is 9; b=c=0; 2 and R 8 for-OCH 2 -, and R 5 , R 11 for CH 3 , the rest of R(R 1 , R 3 , R 4 , R 6 , R 7 , R 9 , R 10 , R 12 ) is H.

Synthetic example 2

[0137] After adding 200 g of toluene, 9.4 g of phenol (Aldrich Company), 28.8 g of butylene oxide (Aldrich Company) and 0.05 g of benzyltriethylammonium chloride in a nitrogen-filled reflux reactor, react at 90° C. for 24 hours 15.51 g of isocyanoethyl methacrylate (Aldrich Company) was added in the product obtained, and 0.05 g of dibutyltin dilaurate (Aldrich Company) was added as a catalyst, and then reacted at 60° C. for 24 hours, and the Removing unreacted matter and solvent by distillation, thereby producing the acrylate oligomer represented by Chemical Formula 1, wherein n=1; R is CH 3 ; x=4; y=z=0; a=4; b=c=0; Y is R in chemical formula 3 1 for -CH 2 NHC(=O)-, and the rest R 2 to R 6 for H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com