Probiotics active soybean milk beverage and preparation method thereof

A technology for probiotics and soymilk, applied in dairy products, milk replacers, applications, etc., to achieve the effects of reducing pollution risks, good stability and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

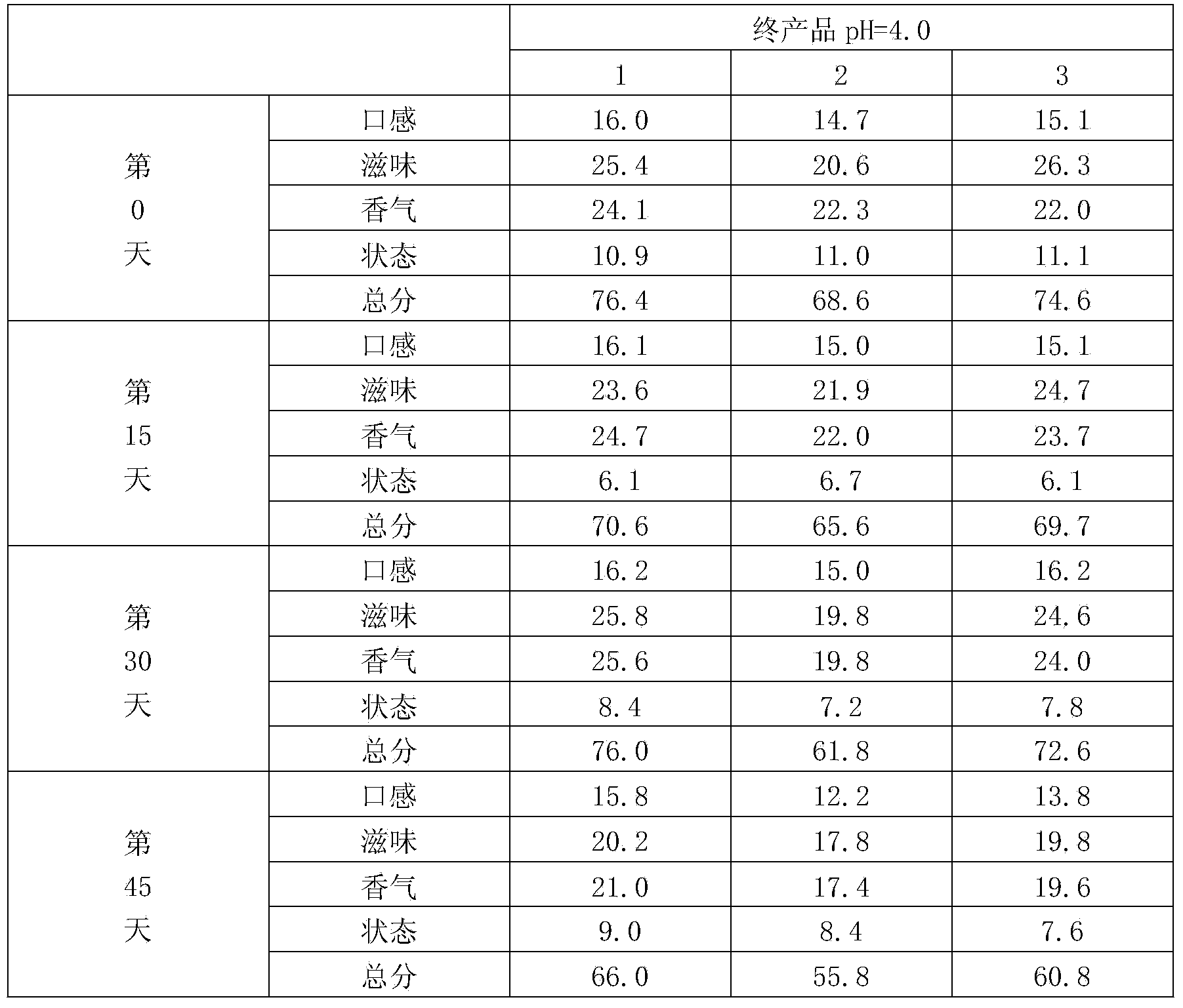

Embodiment 1

[0022] 1. Raw material formula (calculated in 1000 grams)

[0023] 15 grams of defatted soybean protein powder; 65 grams of fructose; 90 grams of soybean polysaccharide; 0.01 grams of Lactobacillus casei Zhang; 0.005 grams of Bifidobacterium lactis V9, and the balance of water.

[0024] 2. Preparation method

[0025] 1. Fermentation process

[0026] Dry mix soybean protein powder, fructose and soybean polysaccharide, dissolve in demineralized water at 55°C, hydrate for 30 minutes, homogenize at 30MPa, sterilize at 90°C for 8 minutes, cool to 37°C, add Lactobacillus casei Zhang and Bifidobacterium V9, Stir evenly, ferment at a constant temperature of 37°C for 24 hours, then stir and lower the temperature to 20°C and continue to ferment for 24 hours, when the pH value reaches 4.0, cool to stop fermentation, and set aside.

[0027] 2. Filling process

[0028] Cool the fermentation feed liquid to 8°C, homogenize it at 20 MPa under aseptic conditions, until it is aseptic to be f...

Embodiment 2

[0031] 1. Raw material formula (calculated in 1000 grams)

[0032] 15 grams of defatted soybean protein powder; 50 grams of fructose; 60 grams of soybean polysaccharide; 0.01 grams of Lactobacillus casei Zhang; 0.01 grams of Bifidobacterium lactis V9; the balance of water.

[0033] 2. Preparation method:

[0034] 1. Fermentation process

[0035] Dry mix soybean protein powder, fructose and soybean polysaccharide, dissolve in demineralized water at 55°C, hydrate for 35min, homogenize at 40MPa, sterilize at 95°C for 5min, cool to 37°C, add Lactobacillus casei Zhang and Bifidobacterium V9, Stir evenly, ferment at a constant temperature of 37°C for 24 hours, then stir and lower the temperature to 20°C and continue to ferment for 24 hours, when the pH value reaches 4.0, cool to stop fermentation, and set aside. 2. Filling process

[0036] Cool the fermentation feed liquid to 8°C, homogenize it at 18MPa under aseptic conditions, wait until it is aseptic to be filled in cans, and as...

Embodiment 3

[0038] 1. Raw material formula (calculated in 1000 grams)

[0039] 12 grams of defatted soybean protein powder; 50 grams of fructose; 60 grams of soybean polysaccharide; 0.005 grams of Lactobacillus casei Zhang; 0.01 grams of Bifidobacterium lactis V9; the balance of water.

[0040] 2. Preparation method:

[0041] 1. Fermentation process

[0042] Dry mix soybean protein powder, fructose and soybean polysaccharide, dissolve in demineralized water at 55°C, hydrate for 35min, homogenize at 40MPa, sterilize at 95°C for 5min, cool to 37°C, add Lactobacillus casei Zhang and Bifidobacterium V9, Stir evenly, ferment at a constant temperature of 37°C for 24 hours, then stir and lower the temperature to 20°C and continue to ferment for 24 hours, when the pH value reaches 4.0, cool to stop fermentation, and set aside. 2. Filling process

[0043] Cool the fermentation feed liquid to 8°C, homogenize it at 18MPa under aseptic conditions, wait until it is aseptic to be filled in cans, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com