No-alum potato starch product containing compound additive and preparation method thereof

A technology of compound additive and potato starch, which is applied in the field of food processing, can solve the problems of unsatisfactory use effect and processing technology of alum substitutes, and achieve the effects of enriching nutritional value and health care effect, convenient use and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

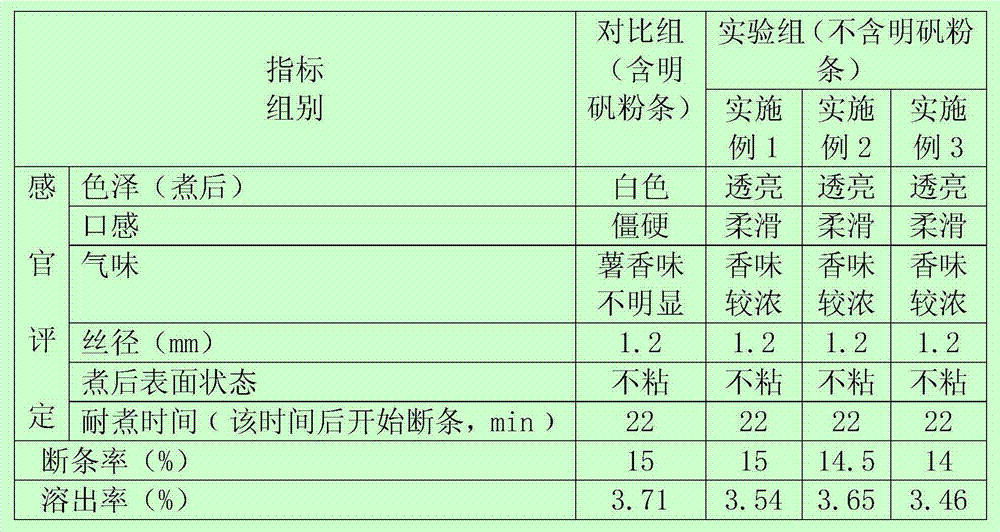

Embodiment 1

[0024] An alum-free potato vermicelli containing compound additives, comprising the following raw materials: 91 kg of tuber starch, 6 kg of chestnut starch, 3 kg of high amylose corn starch, and 0.5 kg of compound additives; the compound additive includes the following raw materials: thorny cloud gum 0.2 kg , Hollyhock gum 0.1kg, salt 0.1kg, potassium dihydrogen phosphate 0.06kg, calcium chloride 0.04kg.

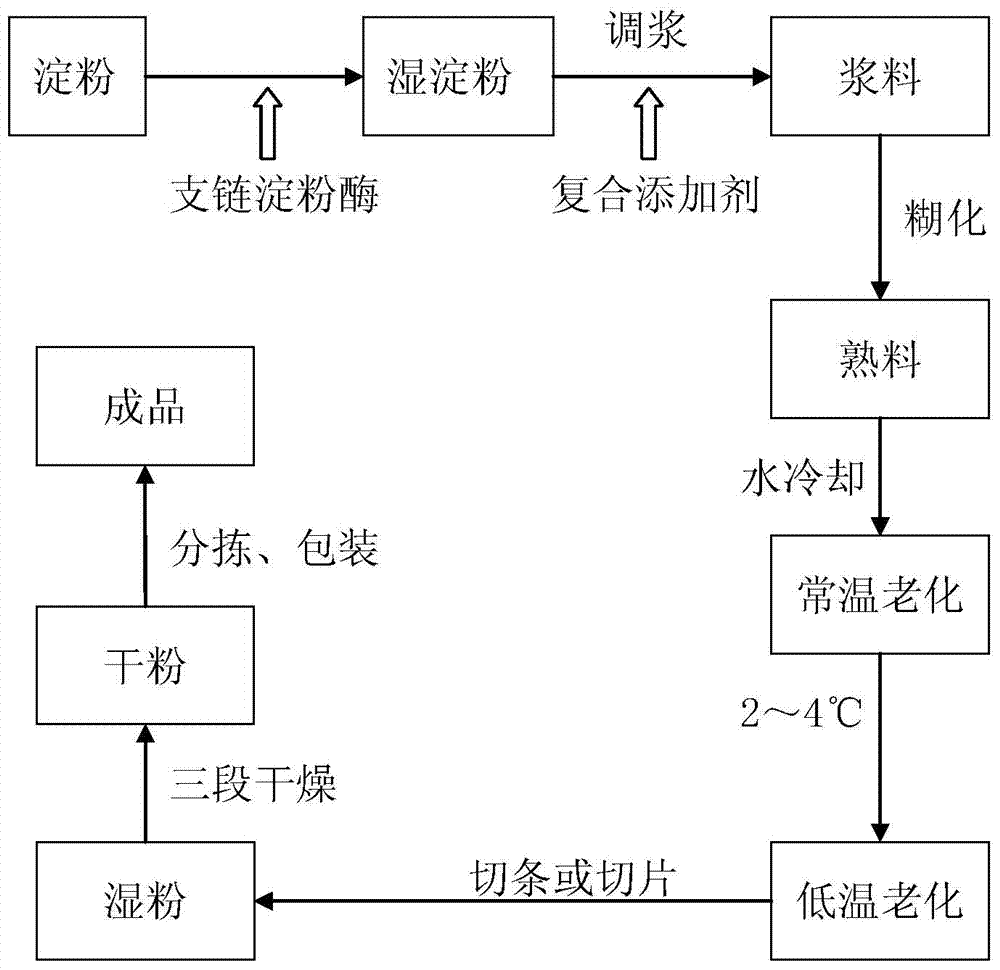

[0025] A method for preparing alum-free potato vermicelli containing compound additives includes the following specific steps:

[0026] ⑴Amylopectin degradation: Weigh the potato starch and chestnut starch according to the formula and mix them into mixed starch. Take 95% of the mixed starch, add 1.2 times the amount of water to it, and add pullulanase in the amount of 3.5mg / kg, enzymatically hydrolyzed at 40°C and pH6.5 for 35min, after stirring and clarification, the precipitated wet starch was taken out, and the wet starch contained 54% water;

[0027] ⑵Mixing and maturation: Ta...

Embodiment 2

[0030] An alum-free potato vermicelli containing compound additives, comprising the following raw materials: 96kg potato starch, 3kg chestnut starch, 1kg high amylose corn starch, and 0.3kg compound additives; the compound additive includes the following raw materials: thorny cloud gum 0.1kg, 0.1 kg of hollyhock gum, 0.05 kg of salt, 0.04 kg of potassium dihydrogen phosphate, and 0.01 kg of calcium chloride.

[0031] The preparation method of the composite additive-free potato vermicelli described in this example is the same as that of Example 1.

Embodiment 3

[0033] An alum-free potato vermicelli containing compound additives, comprising the following raw materials: 93kg potato starch, 5kg chestnut starch, 2kg high amylose corn starch, and 0.8kg compound additive; said compound additive includes the following raw materials: thorny cloud gum 0.2kg, 0.2 kg of hollyhock gum, 0.2 kg of salt, 0.15 kg of potassium dihydrogen phosphate, and 0.05 kg of calcium chloride.

[0034] The preparation method of the composite additive-free potato vermicelli described in this example is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com