A kind of preparation method of chitosan/graphene oxide/hydroxyapatite/polyacrylamide composite material

A technology of hydroxyapatite and polyacrylamide, which is used in medical science, prosthesis and other directions, can solve the problems of lack of energy dissipation mechanism, low mechanical strength, low ductility, etc., to overcome poor mechanical properties and mechanical properties. The effect of enhancing and enhancing the mechanical properties of compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

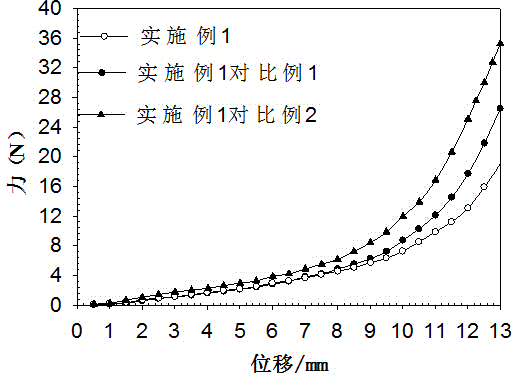

Embodiment 1

[0025] Example 1: Preparation method of chitosan / graphene oxide / hydroxyapatite / polyacrylamide composite material

[0026] (1) Prepare hydroxyapatite (HA) aqueous solution: Dissolve 0.1g of 12μm hydroxyapatite (HA) powder in 5mL of secondary water, and shake and stir to make it fully dissolved, that is, a concentration of 0.02g / mL is obtained Milky white HA solution;

[0027] (2) Preparation of chitosan (CS) aqueous solution: Dissolve 0.05g of chitosan (CS) powder in 5mL of secondary water, then add 0.2mL of acetic acid, and finally shake and stir to make it fully and quickly dissolved, that is, the concentration is 0.01 g / mL milky yellow CS solution;

[0028] (3) Preparation of graphene oxide (GO) aqueous solution: Dissolve 0.01g of graphene oxide (GO) powder in 5mL of secondary water, then shake and stir to make it fully and quickly dissolved, that is, a black and translucent GO with a concentration of 0.002g / mL is obtained Solution

[0029] (4) Preparation of cross-linking agent ...

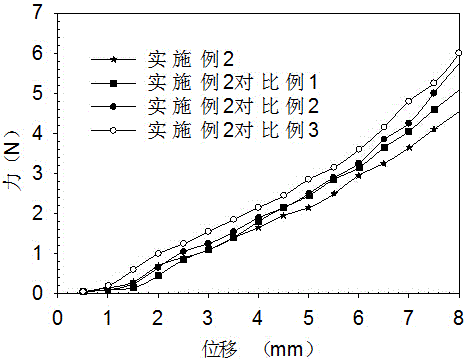

Embodiment 2

[0043] Example 2: Preparation method of chitosan / graphene oxide / hydroxyapatite / polyacrylamide composite material

[0044] (1) Prepare hydroxyapatite (HA) aqueous solution: Dissolve 0.2g of 12μm hydroxyapatite (HA) powder in 10mL of secondary water, and shake and stir to make it fully dissolved, that is, a concentration of 0.02g / mL is obtained. Milky white HA solution;

[0045] (2) Preparation of graphene oxide (GO) aqueous solution: Dissolve 0.02g of graphene oxide (GO) powder in 10mL of secondary water, then shake and stir to make it fully dissolved, then a black and translucent GO solution with a concentration of 0.002g / mL is obtained ;

[0046] (3) Preparation of chitosan (CS) aqueous solution: Dissolve 0.1g of chitosan (CS) powder in 10mL of secondary water, then add 0.2mL of acetic acid, and finally shake and stir to make it fully and quickly dissolved, that is, the concentration is 0.01 g / mL milky yellow CS solution;

[0047] (4) Preparation of cross-linking agent aqueous sol...

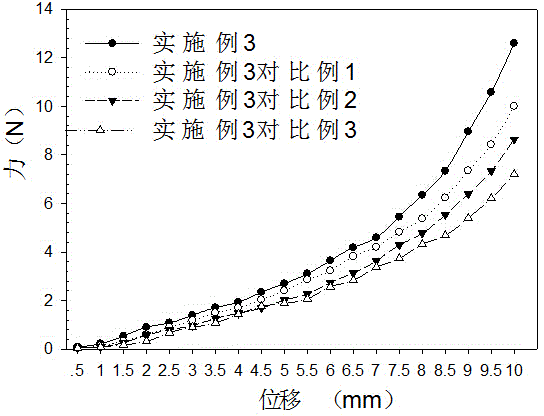

Embodiment 3

[0064] Example 3: Preparation method of chitosan / graphene oxide / hydroxyapatite / polyacrylamide composite material

[0065] (1) Prepare hydroxyapatite (HA) aqueous solution: Dissolve 0.4g hydroxyapatite (HA) powder of 12μm in 10mL of secondary water, and shake and stir to make it fully dissolved, that is, a concentration of 0.04g / mL is obtained Milky white HA solution;

[0066] (2) Preparation of graphene oxide (GO) aqueous solution: Dissolve 0.02g of graphene oxide (GO) powder in 10mL of secondary water, then shake and stir to make it fully dissolved, then a black and translucent GO solution with a concentration of 0.002g / mL is obtained ;

[0067] (3) Preparation of chitosan (CS) aqueous solution: Dissolve 0.1g of chitosan (CS) powder in 10mL of secondary water, then add 0.2mL of acetic acid, and finally shake and stir to make it fully and quickly dissolved, that is, the concentration is 0.01 g / mL milky yellow CS solution;

[0068] (4) Preparation of cross-linking agent aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com