A cylinder-type molecular sieve compression system for a medical oxygen generator and its application method

A molecular sieve and cylinder-type technology, which is applied in the field of cylinder-type molecular sieve compression system for medical oxygen generators, can solve problems such as high working noise, high equipment purchase costs, and insufficient flow, so as to prevent violent movement, ensure stability, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

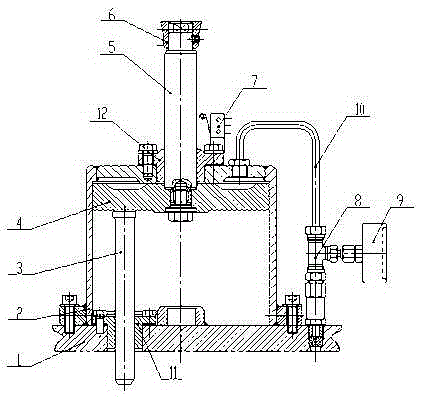

[0019] refer to figure 1 Shown: a cylinder-type molecular sieve compression system for a medical oxygen generator main engine, including an adsorption tower flange cover 1, a cylinder body 2, a piston 4 and a one-way stop valve 8, and the adsorption tower flange cover 1 is fixed to the cylinder body 2 connection, the flange cover 1 of the adsorption tower is provided with a transmission rod 3, and a piston 4 is provided above the inner side of the cylinder body 2, and the transmission rod 3 and the piston 4 are connected in a transmission manner. When in use, the transmission rod 3 will generate The power is transmitted to the piston 4, and the cylinder block 2 is provided with a piston rod 5 and a vent pipe 10, and the compressed oxygen generated is sent out through the vent pipe 10, and is connected to the piston 4 through the piston rod 5, and the piston rod 5 A limit block 6 is arranged on the top, and a one-way stop valve 8 is connected to the ventilation pipe 10. When in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com